-

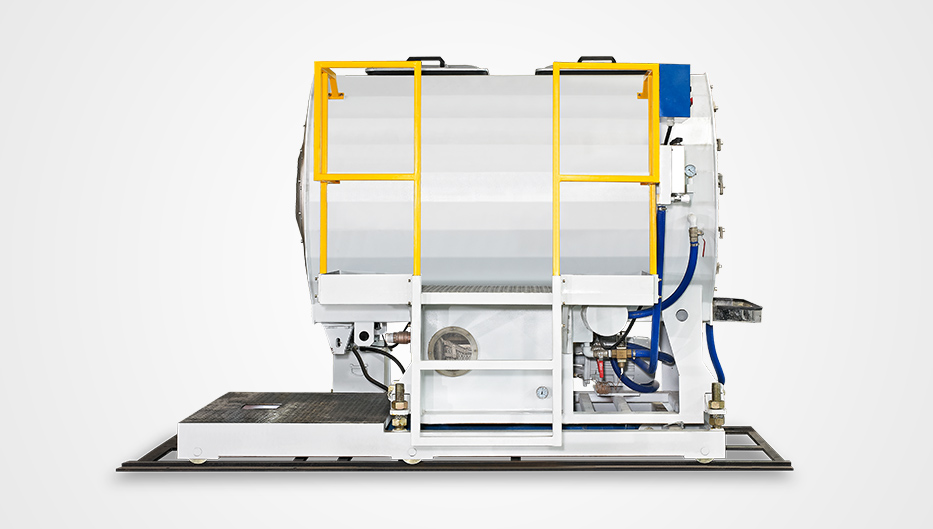

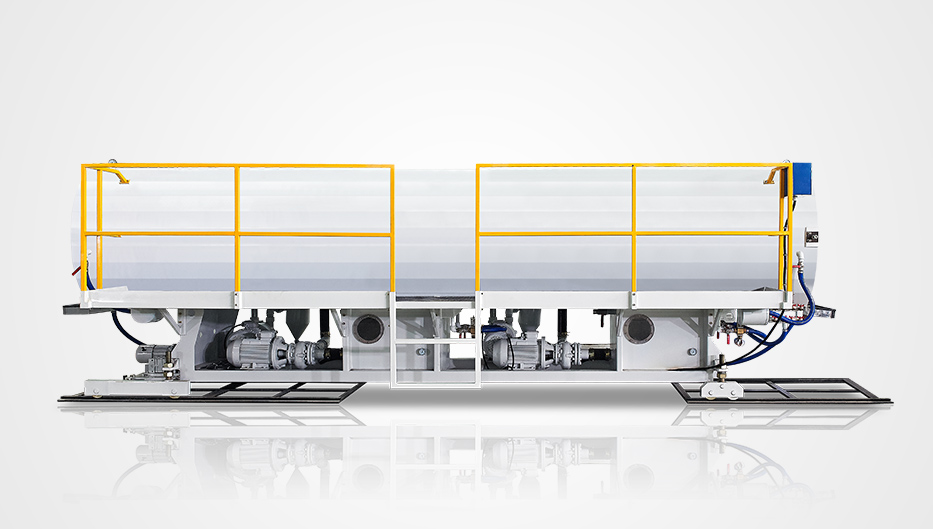

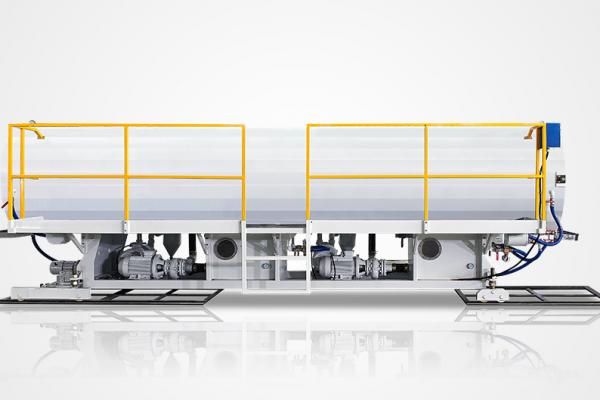

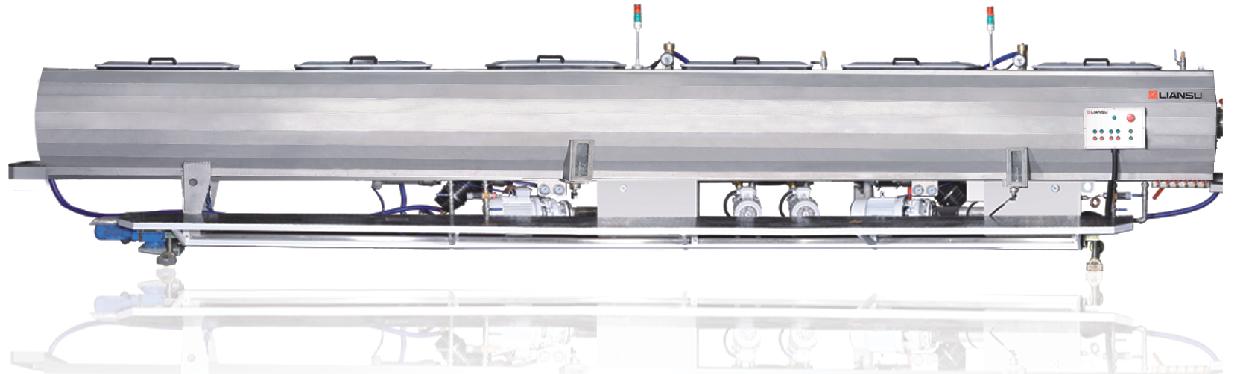

- Bath material - stainless steel, waterproof electrical cabinet, the ability to move back and forth.

- Водный фильтр большой емкости позволяет не проводить чистку в течение длительного времени.

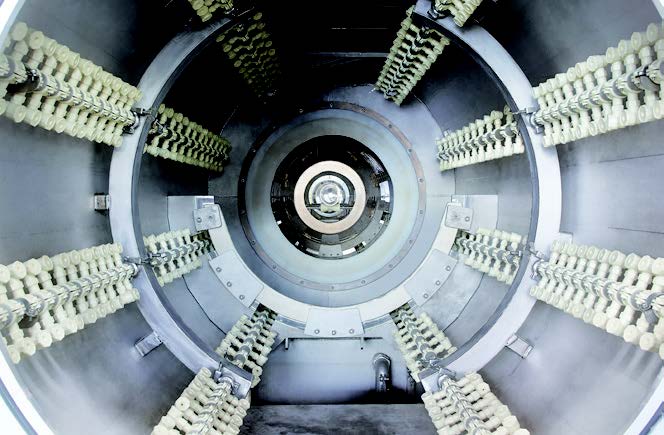

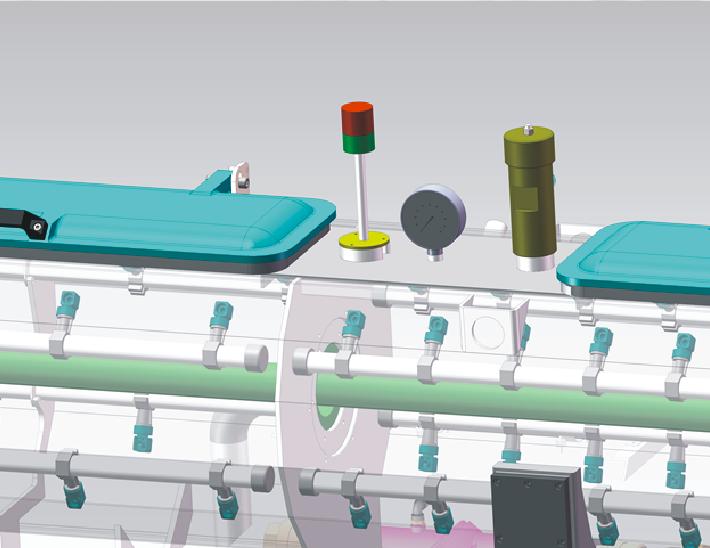

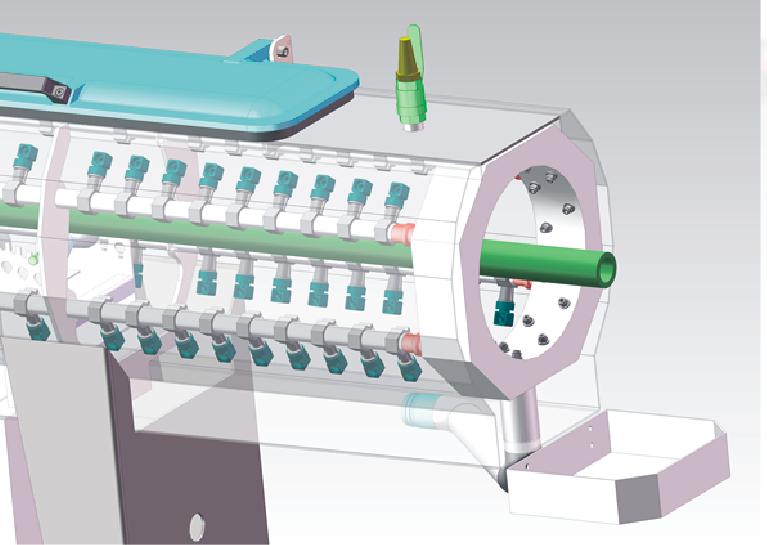

- The annular arrangement of the high-pressure nozzles allows fast cooling of any pipe size.

- Automatic control of the liquid level by a pneumatic valve; water temperature control high degree of automation maintains level and temperature at set values.

- The vacuum valve, which regulates the degree of vacuum, maintains it at the desired level.

- The piping is fitted with stainless steel bends to reduce pump water pressure losses.

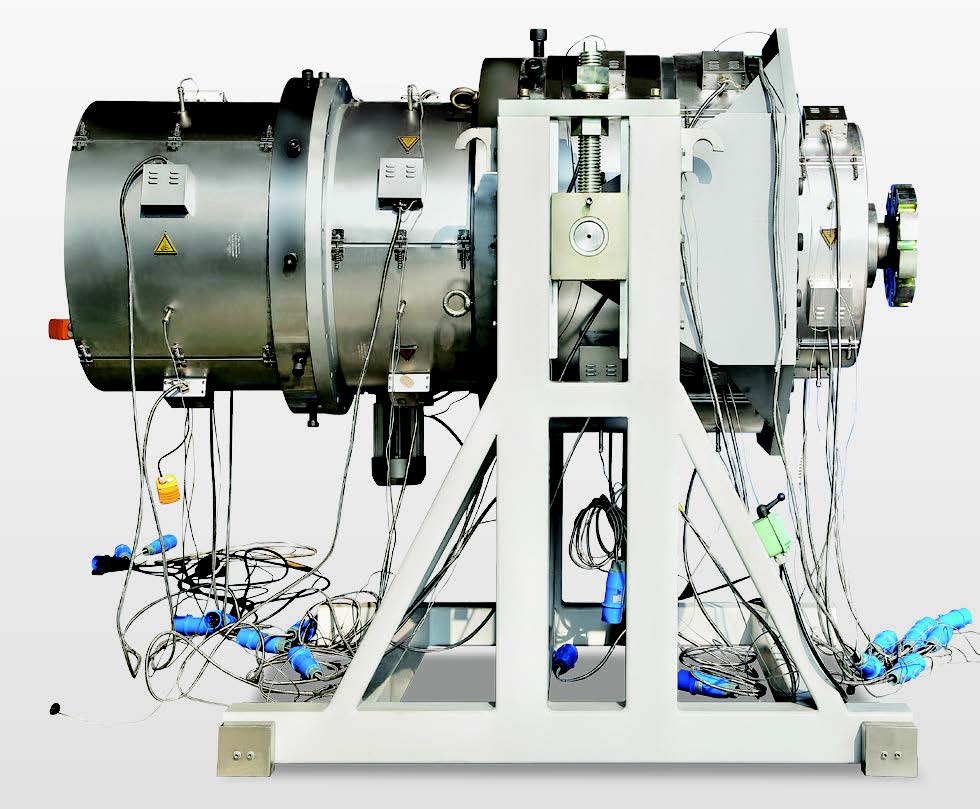

- Equipped with an ovality adjustment device, which allows to restore the round shape of oval pipes.

- A short first vacuum calibration bath for large diameter pipes reduces line start-up scrap.

- It is possible to manufacture bathtubs of various lengths.

-

- Model

- LSPZ-160-9

- LSPZ-250-9

- LSPZ-450-9

- LSPZ-630-10

- Pipes, mm

- 20 — 160

- 50 — 250

- 110 — 450

- 160 — 630

- Vacuum, kw

- 2.2 + 3

- 4 + 4

- 3 + 4

- 5.5 + 5.5

- Length, m

- 2 + 7

- 2 + 7

- 2 + 7

- 2 + 8

* Test and accept based on Liansu standard formula

- Model

- Pipe Range (mm)

- Length (m)

- Vacuum Pump (kw)

- LSPZ-160-9

- 20 — 160

- 2 + 7

- 2.2 + 3

- LSPZ-250-9

- 50 — 250

- 2 + 7

- 4 + 4

- LSPZ-450-9

- 110 — 450

- 2 + 7

- 3 + 4

- LSPZ-630-10

- 160 — 630

- 2 + 8

- 5.5 + 5.5

* Test and accept based on Liansu standard formula

-

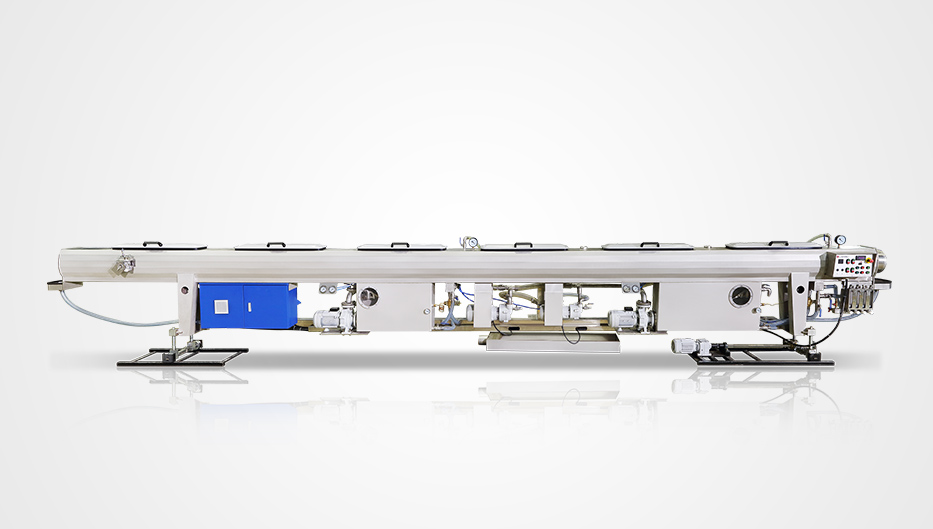

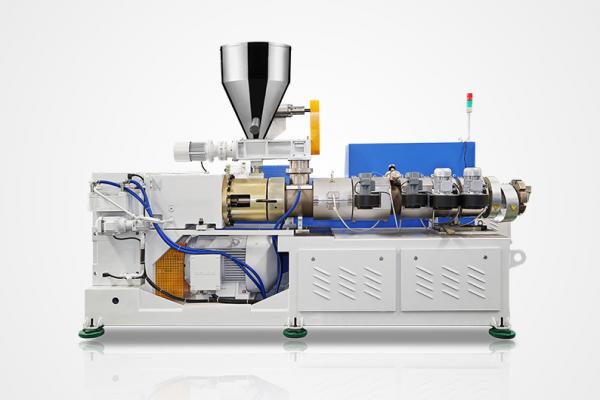

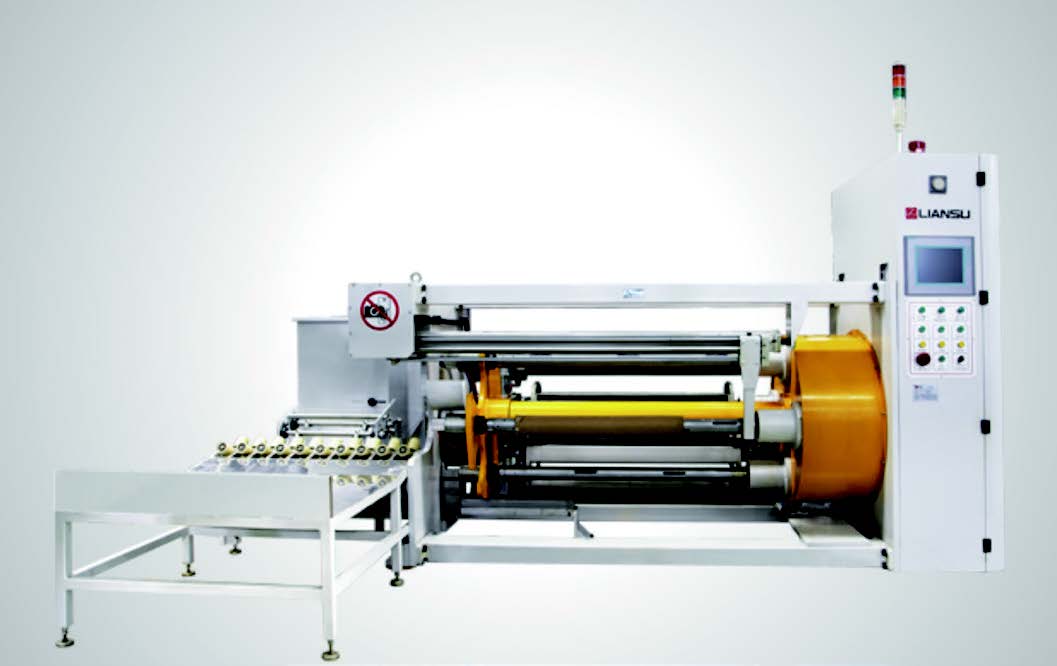

LS-Tank

16-1600

SUITABLE PIPE SIZE RANGE (mm)

2-10

TANK LENGTH (m)

304 STAINLESS

TANK MATERIAL

LS-Tank

16-1600

SUITABLE PIPE SIZE RANGE(mm)

2-10

TANK LENGTH(m)

304 STAINLESS

TANK MATERIAL

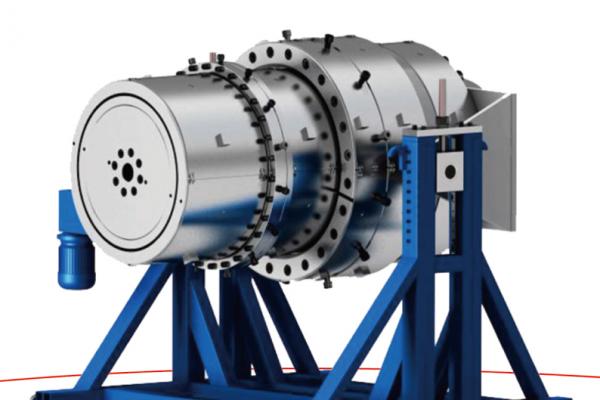

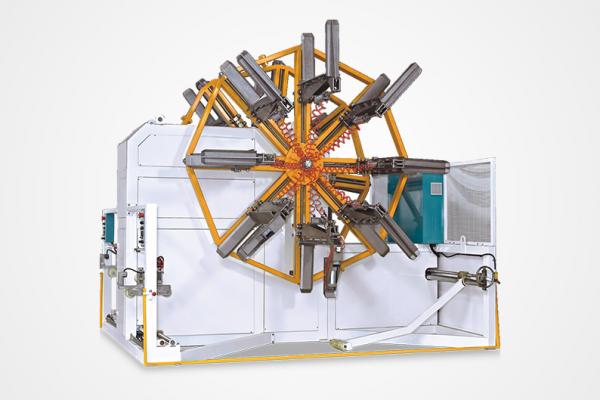

Vacuum adopts negative pressure closed-loop to automatically adjust the vacuum degree, improve the quality of pipe production, reduce noise by more than 30dB, and save energy by 30 ~ 85%.

It adopts vacuum negative pressure closed-loop control, HMI sets the pressure required for pipe sizing, starts the vacuum pump to send signals to inverter through the negative pressure sensor, automatically adjusts the speed of the vacuum pump, quickly achieves the constant negative pressure without manual pressure relief, achieves the energy-saving effect and improves the production stability.

Vacuum adopts negative pressure closed-loop to automatically adjust the vacuum degree, improve the quality of pipe production, reduce noise by more than 30dB, and save energy by 30 ~ 85%.

It adopts vacuum negative pressure closed-loop control, HMI sets the pressure required for pipe sizing, starts the vacuum pump to send signals to inverter through the negative pressure sensor, automatically adjusts the speed of the vacuum pump, quickly achieves the constant negative pressure without manual pressure relief, achieves the energy-saving effect and improves the production stability.

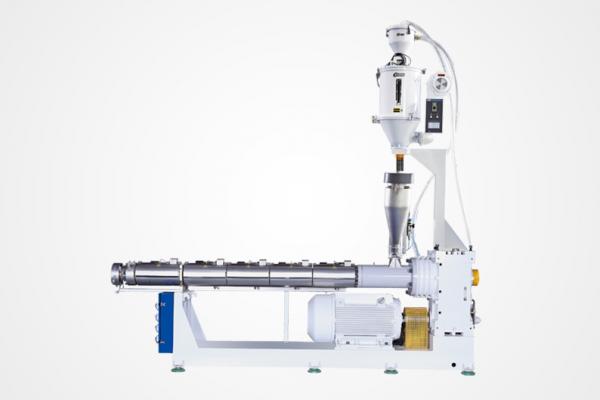

Durability

The whole tank is made of 304 stainless steel, durable and reliable.

Durability

The whole tank is made of 304 stainless steel, durable and reliable.SPRAY TANK

SPRAY TANK

Moscow, Russia