Volokolamskoye shosse 89 bld 1,

Moscow, Russia

-

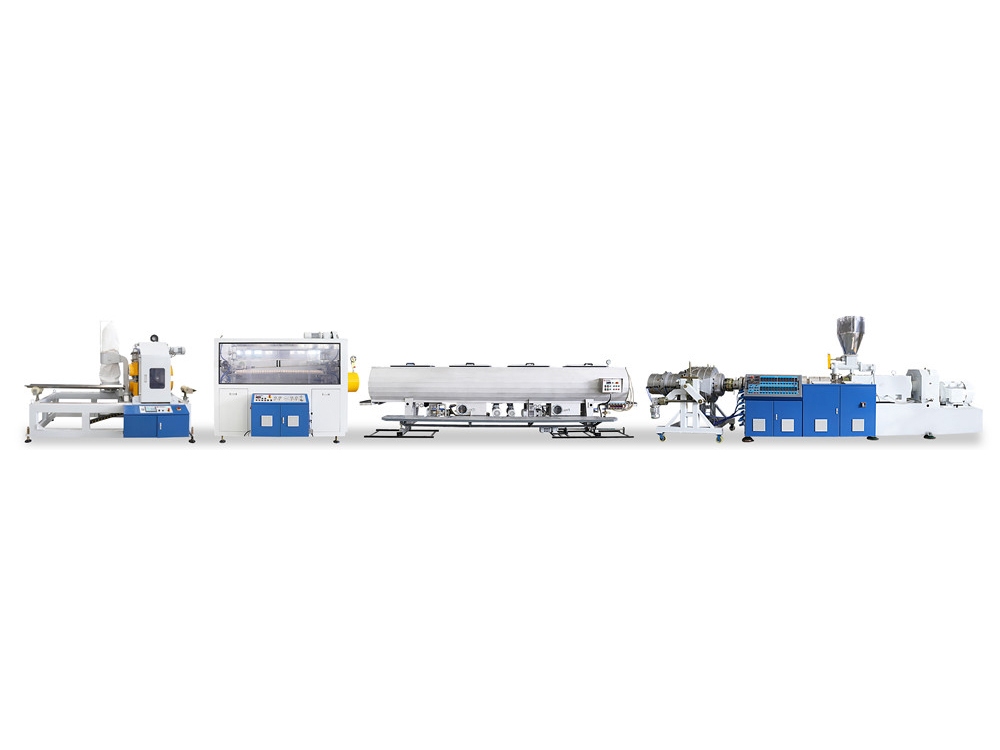

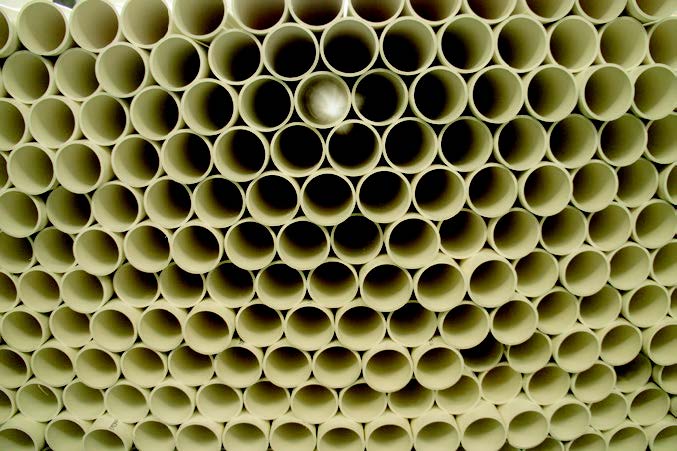

- Extruder with high output more than 1000 kg/h;

- Precise and customized die head design;

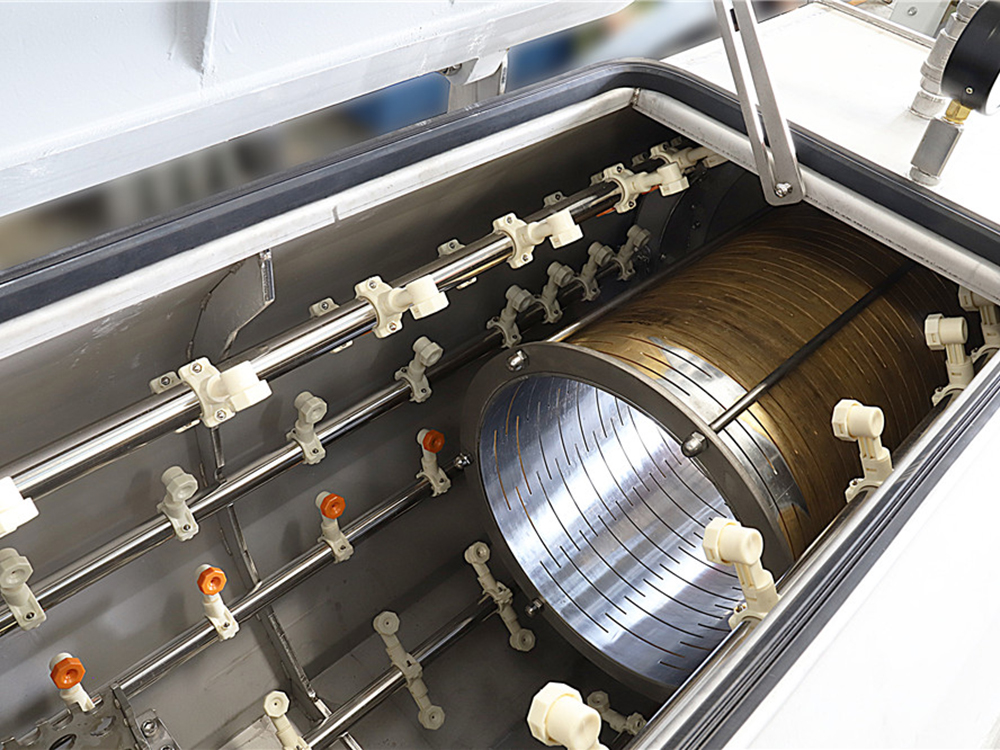

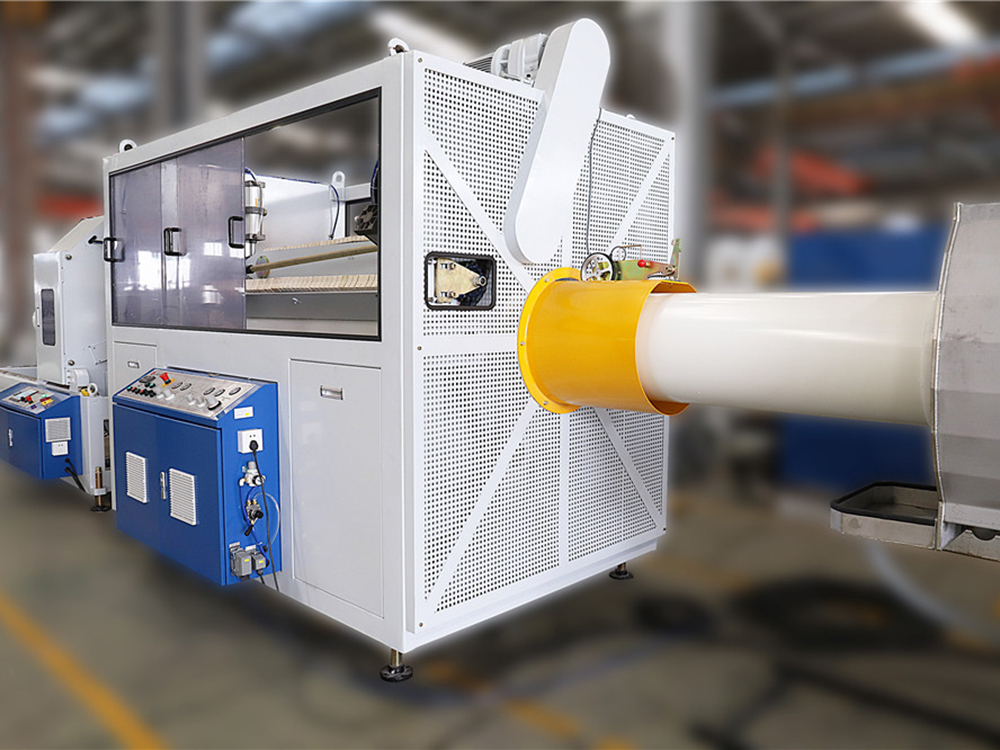

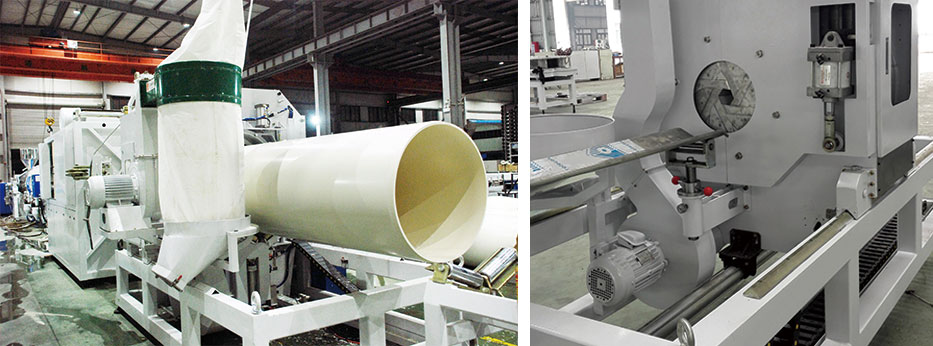

- Double chamber vacuum tank with arc supporter for large diameter pipe,improving pipe formation quality;

- Eight-caterpillar haul-off unit. When producing small pipes, only need to apply four caterpillars to clamp which is energy saving. Optional to use winching machine to reduce the cost of the hauling pipe;

- Planetary cutting, uniform chamfer;

- Optional to use with on-line socketing machine.

-

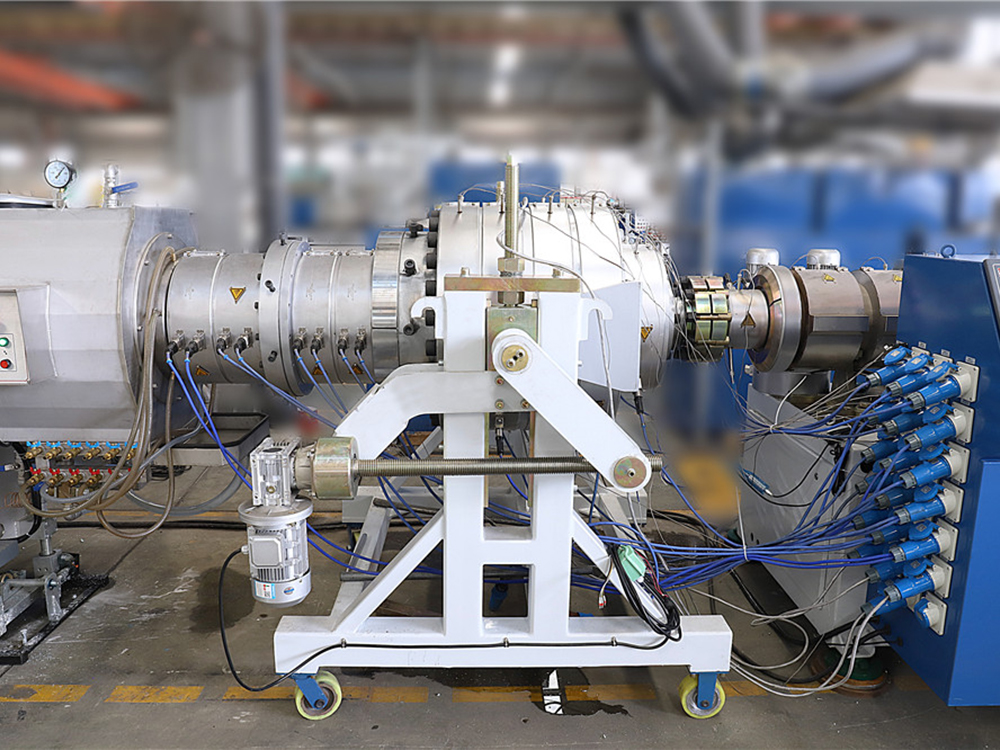

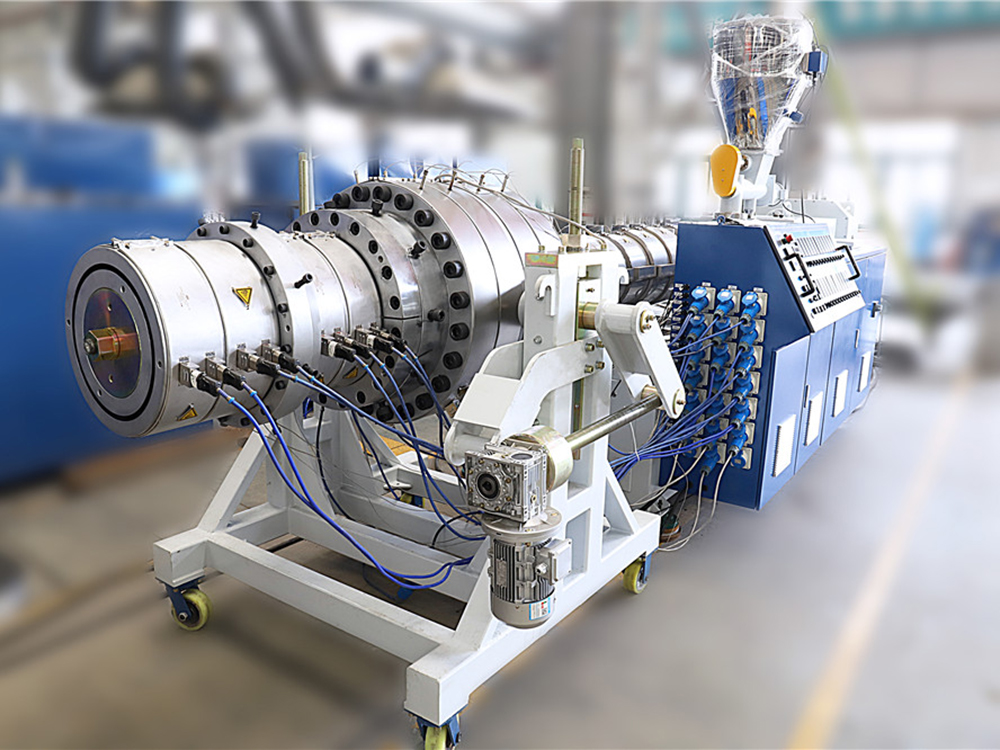

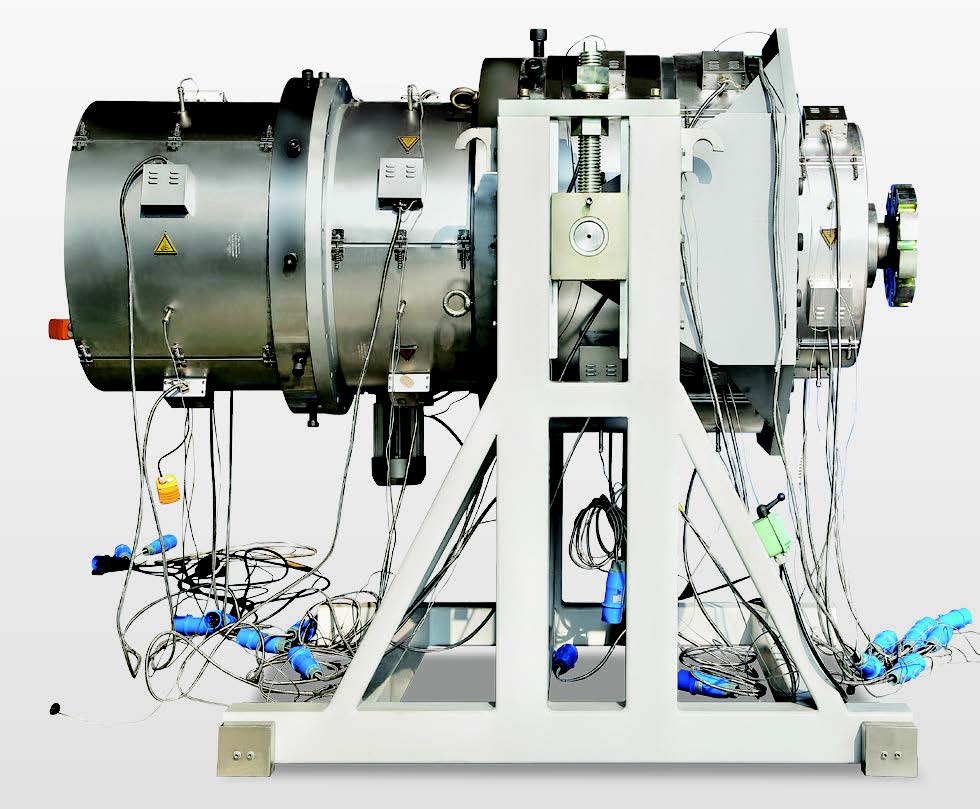

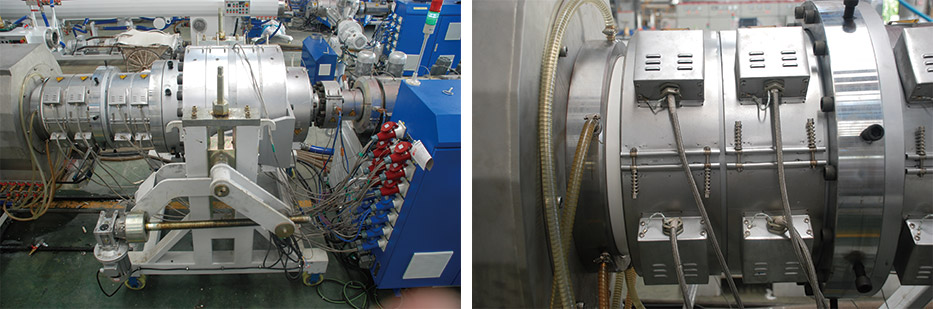

DIE HEAD

- Spacious flow channel design to guarantee high extrusion capacity and good melt.

- Mould structure with positioning bolts, mould can be assembled and disassembled fast and accurately.

- Optimized temperatue control and flow channel design, precise melt temperature control

VACUUM TANK

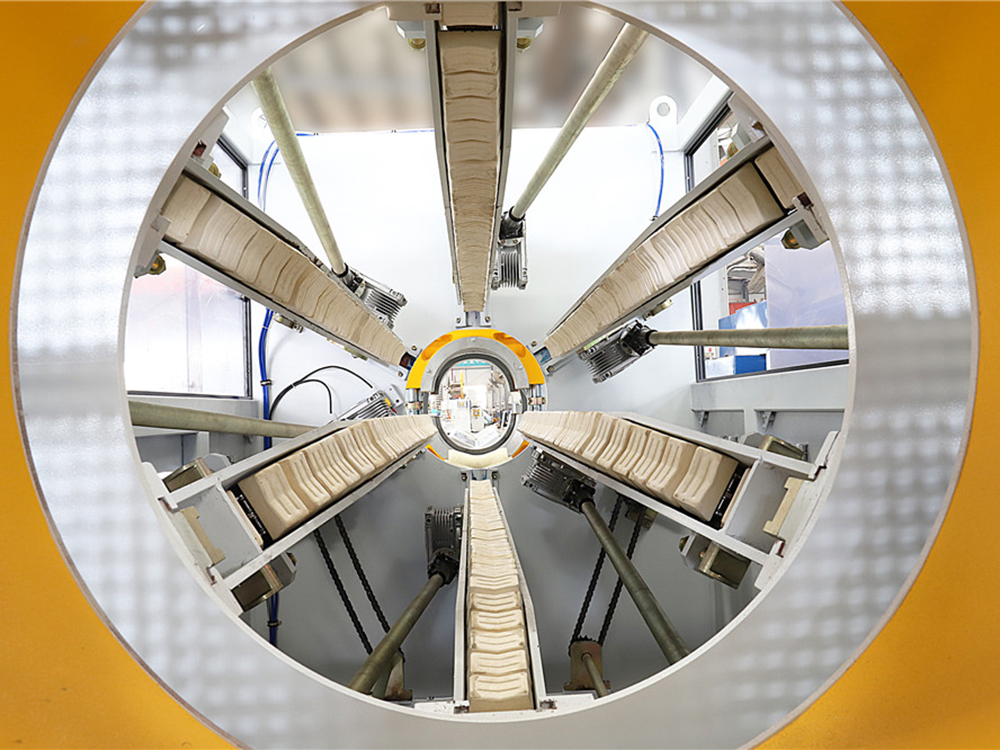

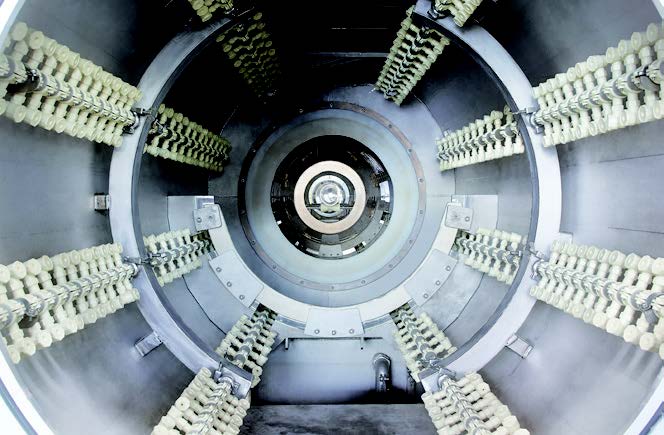

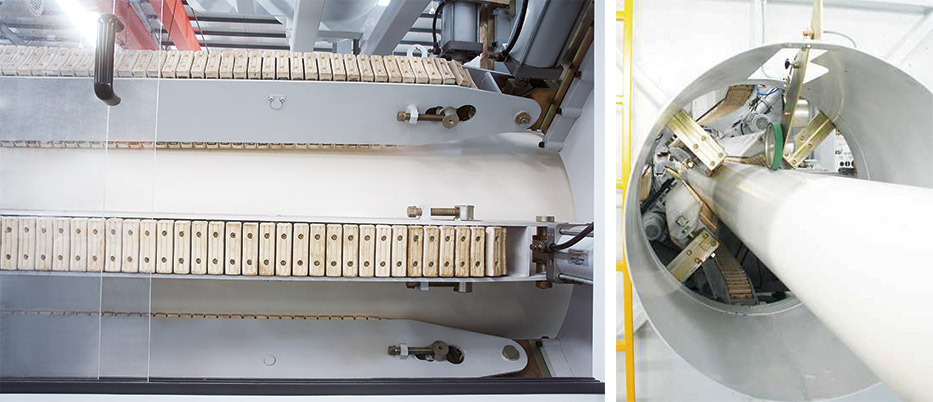

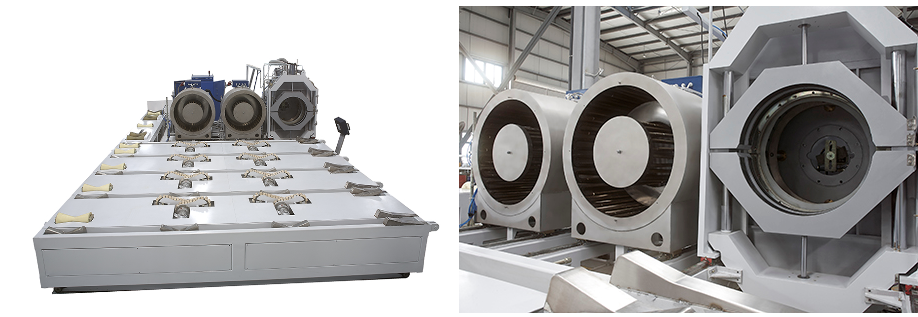

HAUL - OFF UNIT

CUTTER

- New model of planetary cutting design, endurable, dustcollecting efficiently, and quiet.

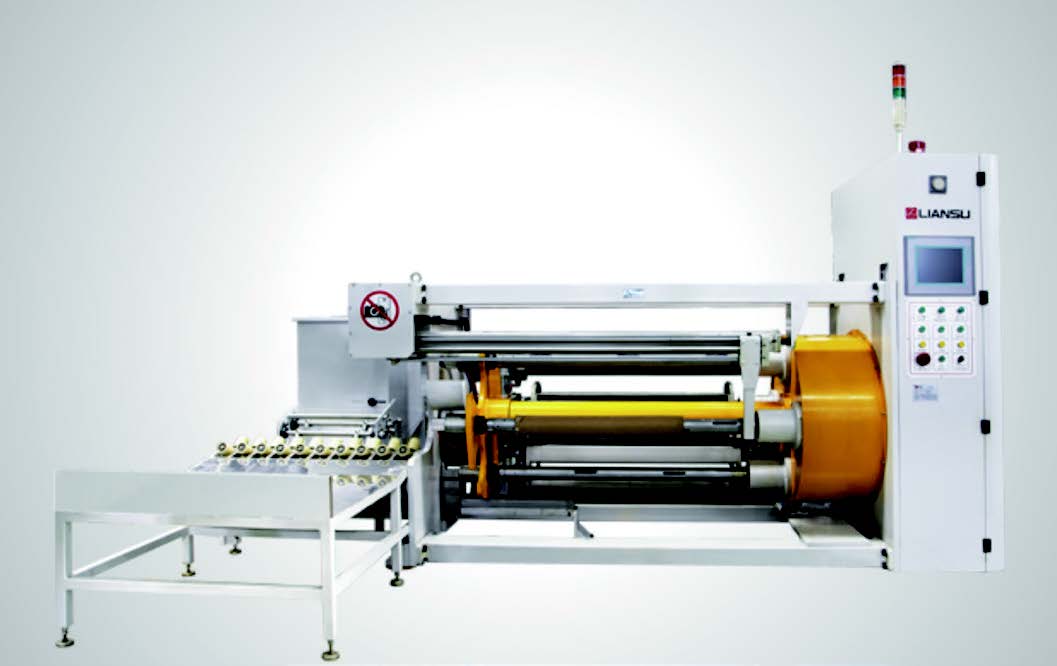

SOCKETING PIPE

- Provide enough and even heating power inside and outside the pipe to make sure best socketing performance.

-

- Model

- Diameter, mm

- Extruder

- Output, kg/h

- Speed, m/min

- Power, kW

- Length, m

- 63PVC

- Ø16-Ø63

- LSE-55

- 180

- 16

- 90

- 24

- 110PVCⅠ

- Ø20-Ø110

- LSE-65

- 280

- 12

- 110

- 24

- 110PVCⅡ

- Ø63-Ø110

- LSE-80

- 450

- 8

- 180

- 25

- Model

- Diameter, mm

- Extruder

- Output, kg/h

- Speed, m/min

- Power, kW

- Length, m

- 160PVC

- Ø63-Ø160

- LSE-80

- 450

- 8

- 175

- 25

- 250PVCⅡ

- Ø63-Ø250

- LSE-80

- 480

- 8

- 195

- 25

- 400PVC

- Ø110-Ø400

- LSE-92

- 750

- 2.4

- 290

- 32

- Model

- Diameter, mm

- Extruder

- Output, kg/h

- Speed, m/min

- Power, kW

- Length, m

- 630PVC

- Ø160-Ø630

- LSE-92

- 750

- 1.6

- 330

- 33

- 800PVC

- Ø280-Ø800

- LSE-95

- 1000

- 1.6

- 380

- 46

- 1000PVC

- Ø630-Ø1000

- LSE-95

- 1000

- 0.6

- 540

- 50

* Test and accept based on Liansu standard formula

- Model

- Pipe Range, mm

- Extruder Model

- Max Output, kg/h

- Max Hauling Speed, m/min

- Total Installed Power, kW

- Line Length, m

- LSP-63PVC

- Ø16 - Ø63

- LSE-55

- 180

- 16

- 90

- 24

- LSP-110PVC Ⅰ

- Ø20 - Ø110

- LSE-65

- 280

- 12

- 110

- 24

- LSP-110PVC Ⅱ

- Ø63 - Ø110

- LSE-80

- 450

- 8

- 180

- 25

- LSP-160PVC

- Ø63 - Ø160

- LSE-80

- 450

- 8

- 175

- 25

- LSP-250PVC Ⅱ

- Ø63 - Ø250

- LSE-80

- 480

- 8

- 195

- 25

- LSP-400PVC

- Ø110 - Ø400

- LSE-92

- 750

- 2.4

- 290

- 32

- LSP-630PVC

- Ø160 - Ø630

- LSE-92

- 750

- 1.6

- 330

- 33

- LSP-800PVC

- Ø280 - Ø800

- LSE-95

- 1000

- 1.6

- 380

- 46

- LSP-1000PVC

- Ø630 - Ø1000

- LSE-95

- 1000

- 0.6

- 540

- 50

* Test and accept based on Liansu standard formula

-

LSP-400PVC-U Pressure Pipe Line