Volokolamskoye shosse 89 bld 1,

Moscow, Russia

- You are here:

-

Home

-

Products

-

Lines

-

Pipeline Extrusion

-

Plumbing & Heating

- HDPE Multilayer

-

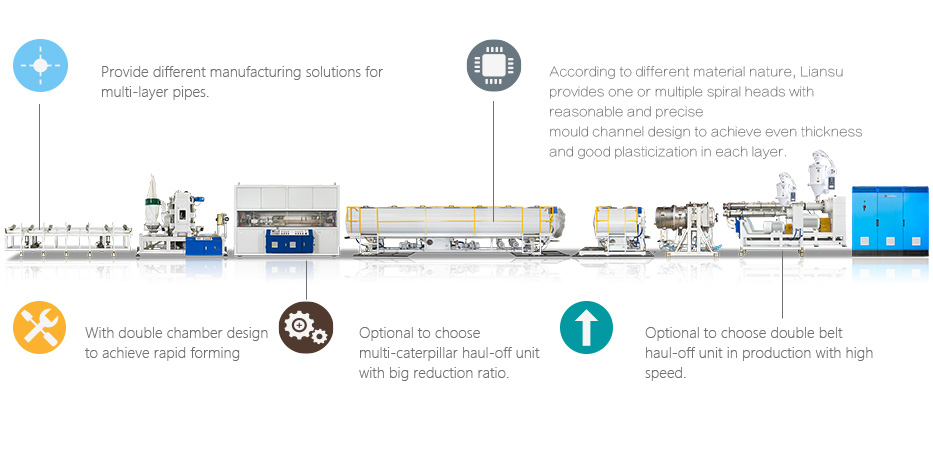

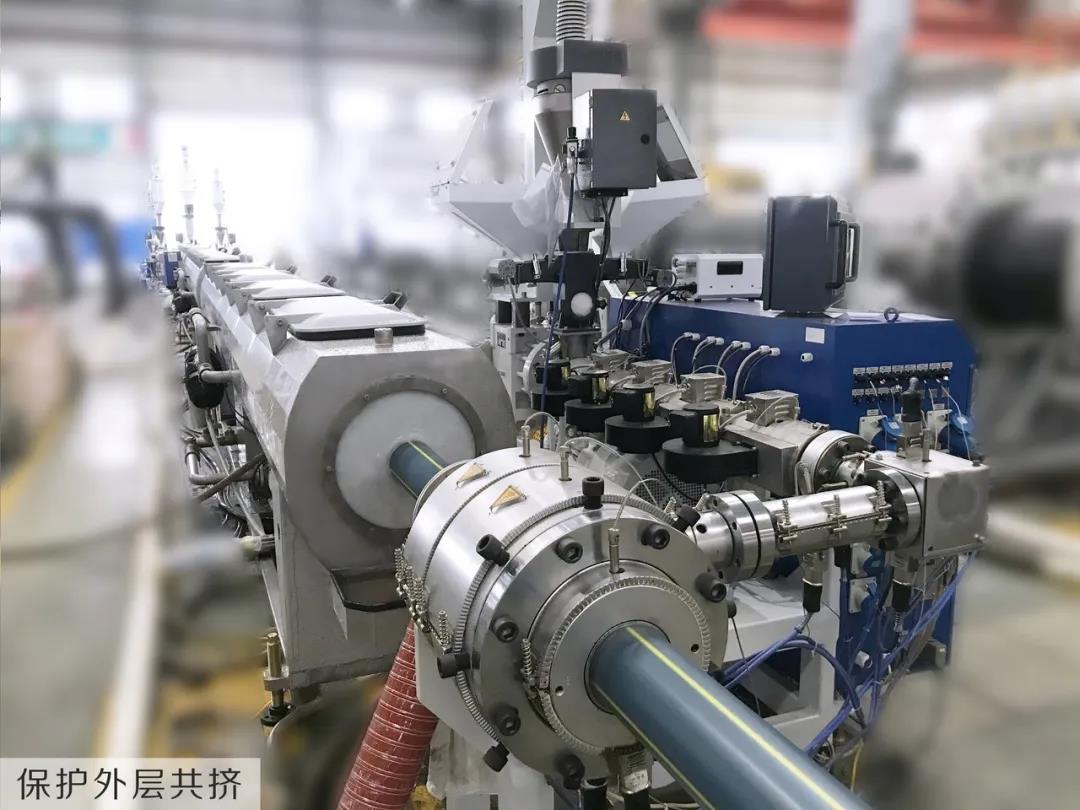

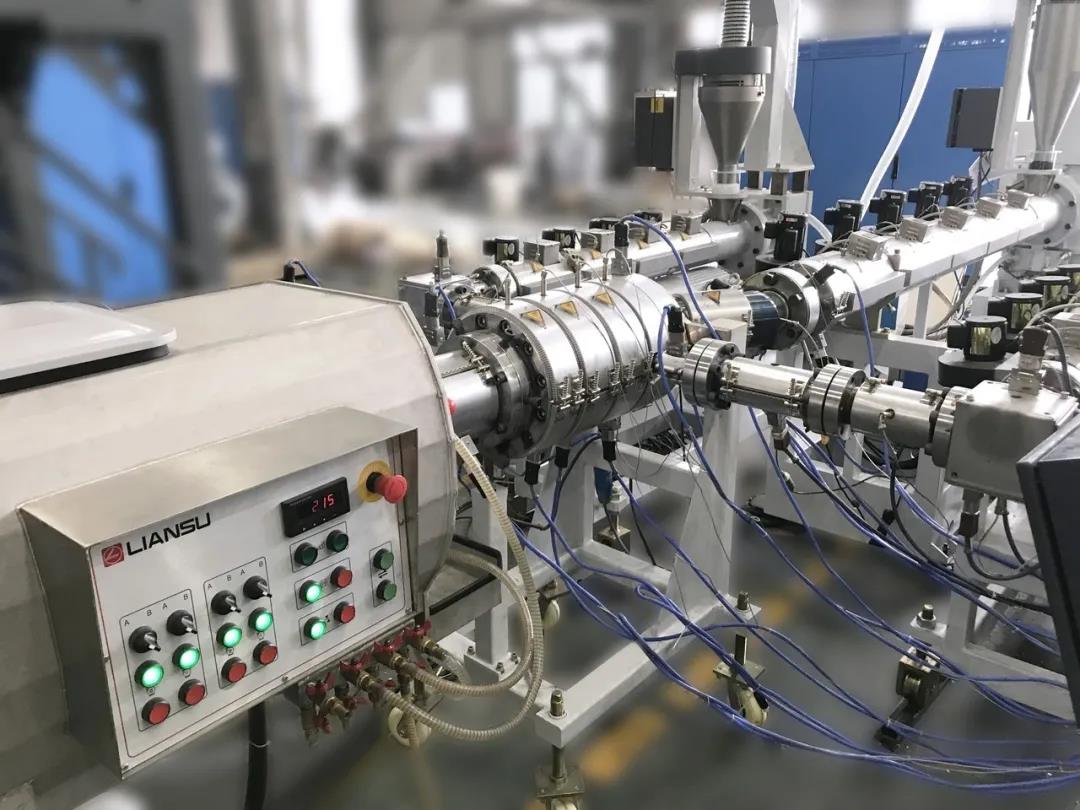

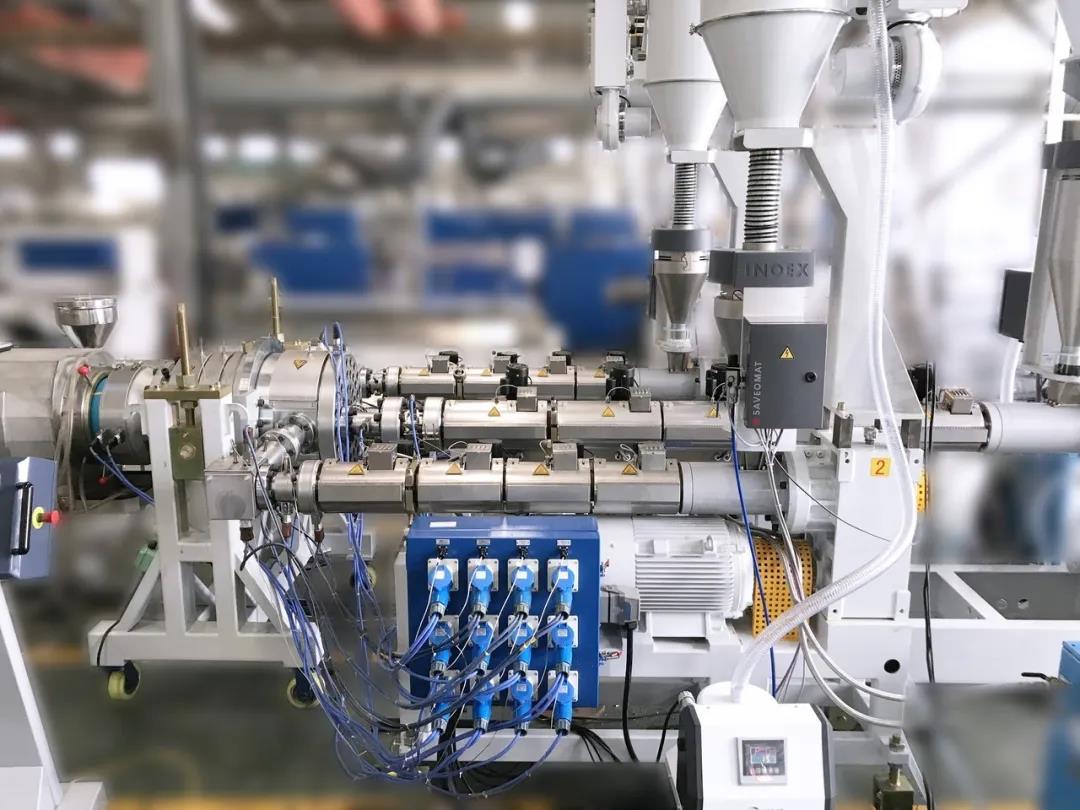

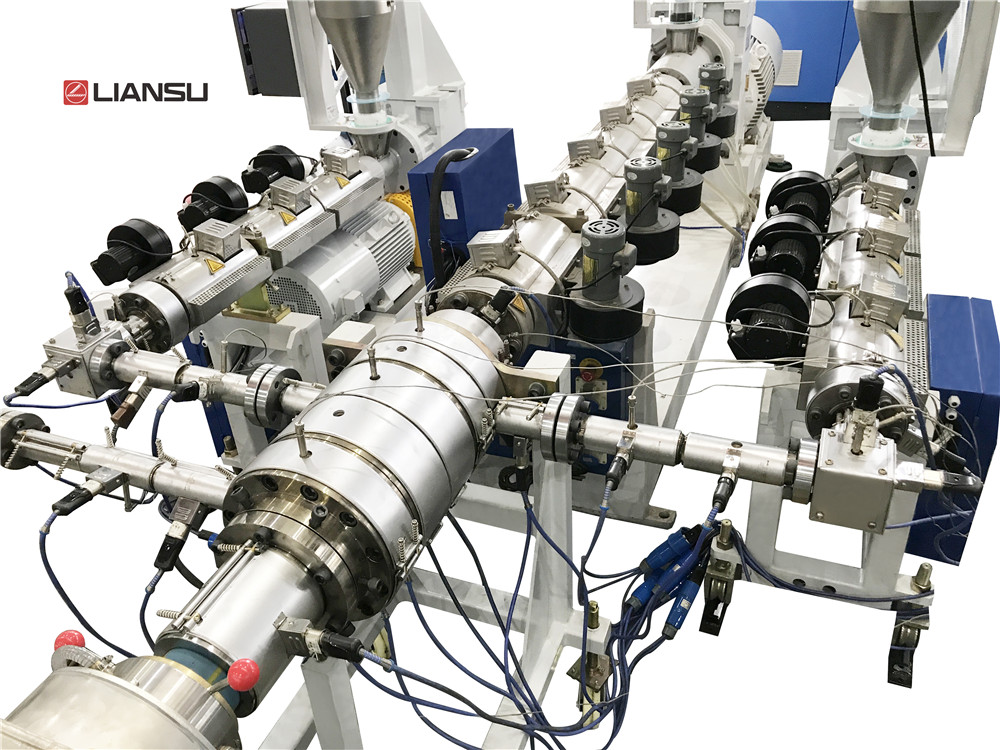

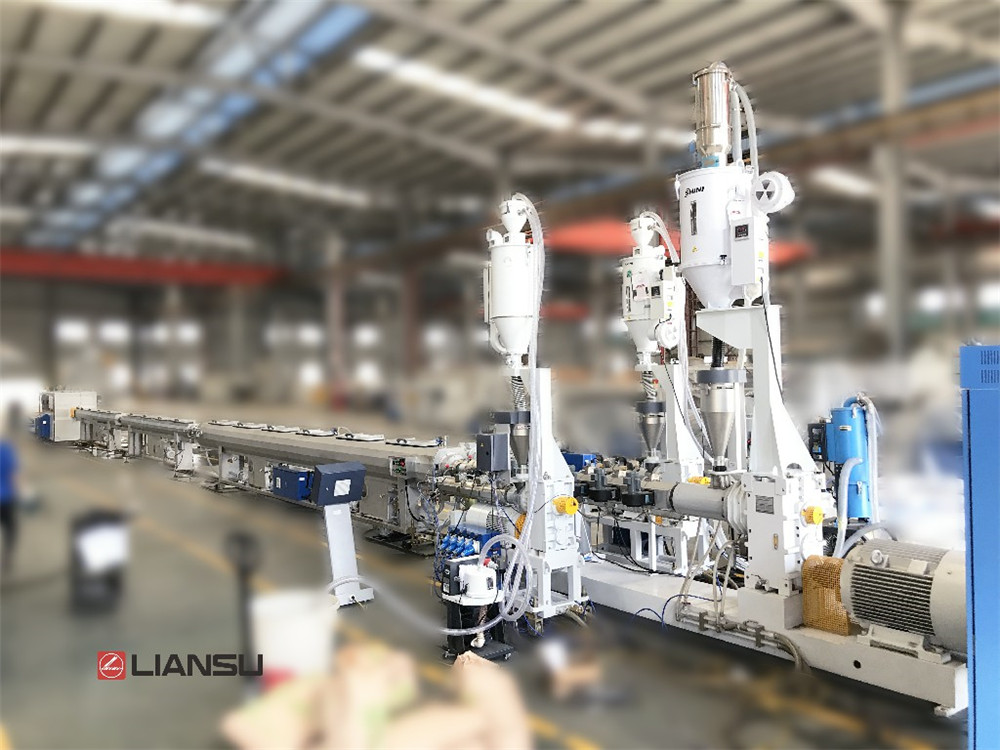

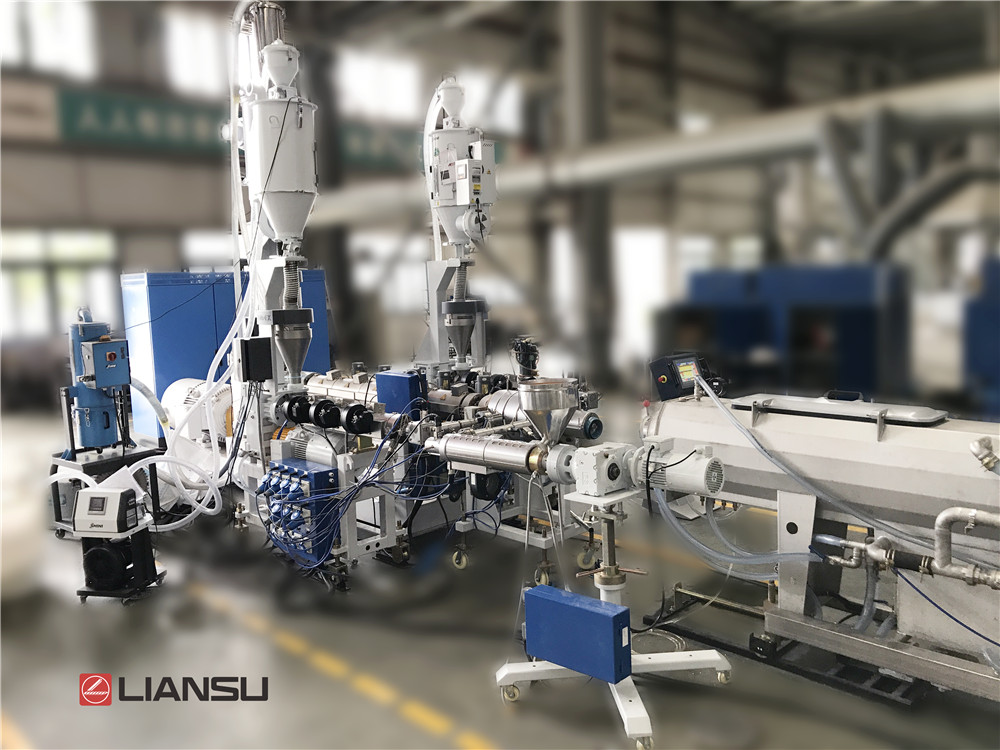

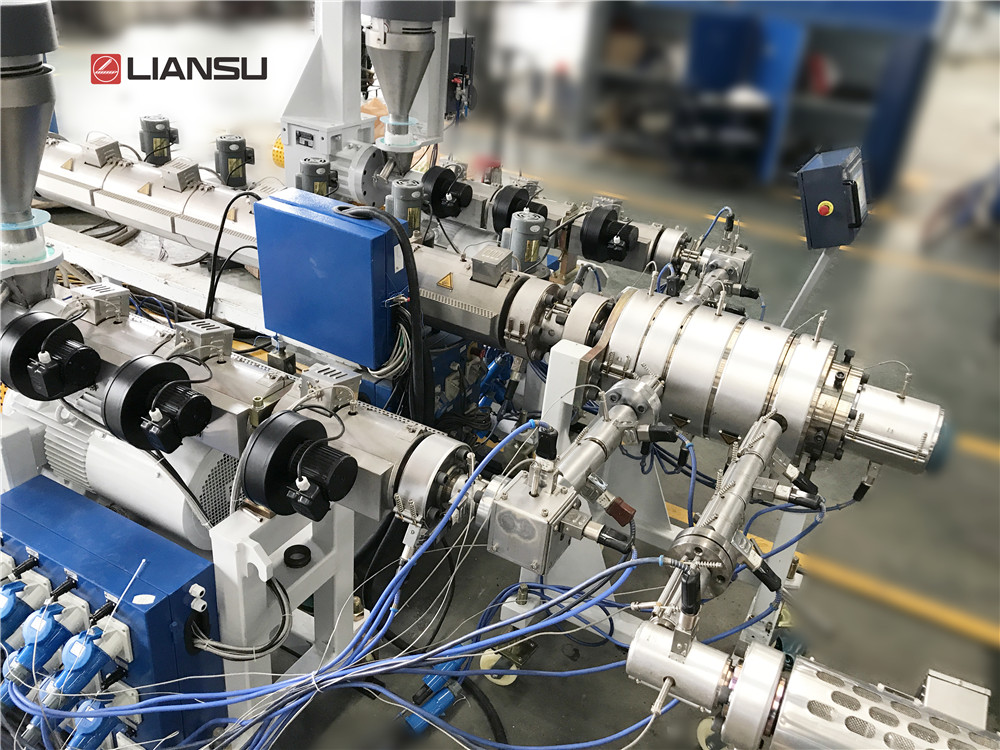

- The extruder adopts large L/D ratio screw and special permanent magnet synchronous servo motor for extruder to realize high production and energy saving.

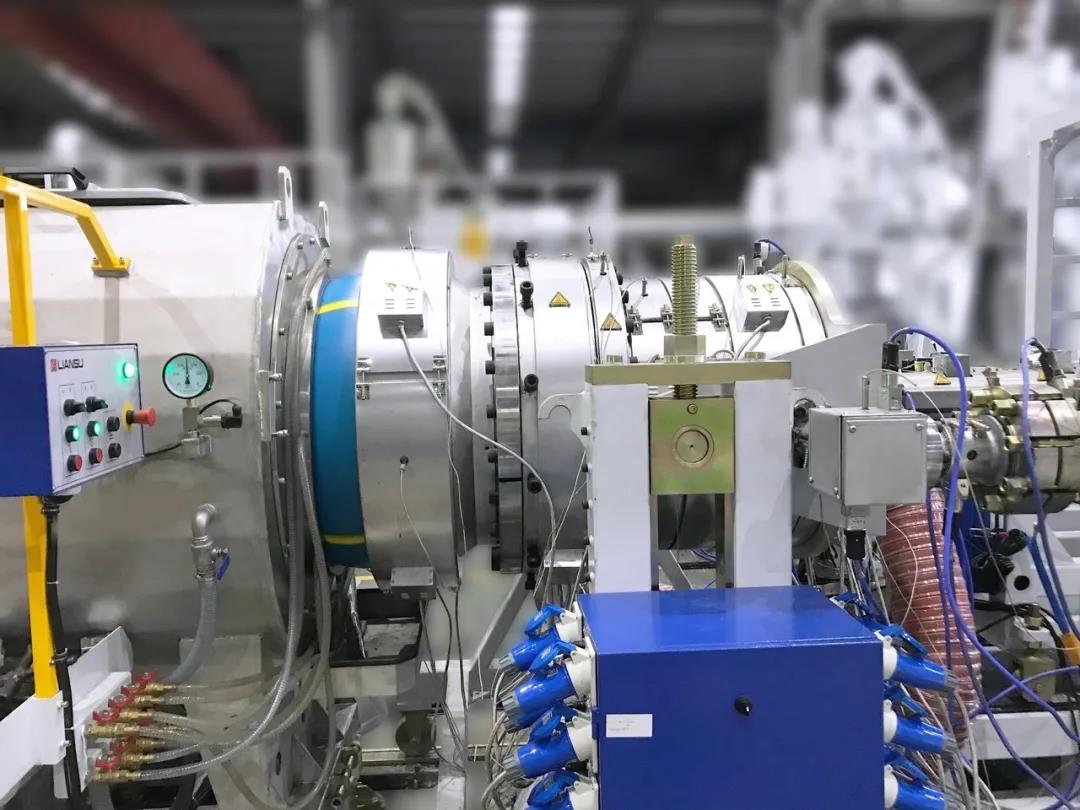

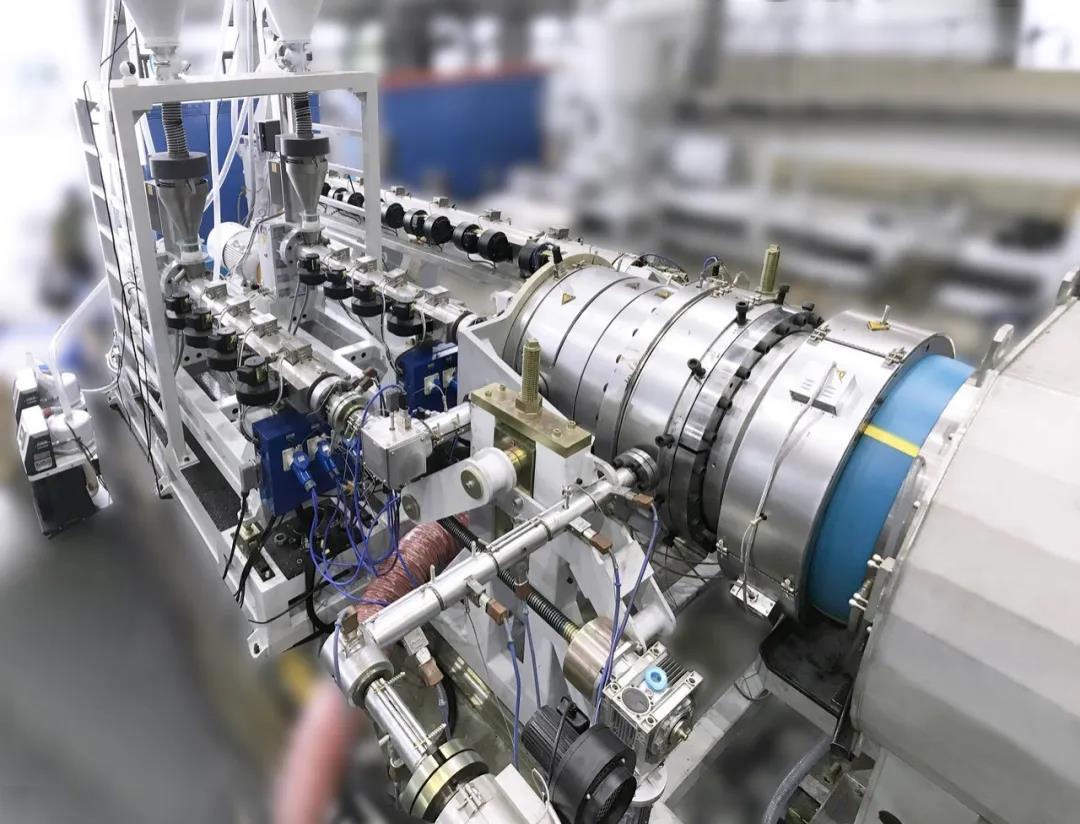

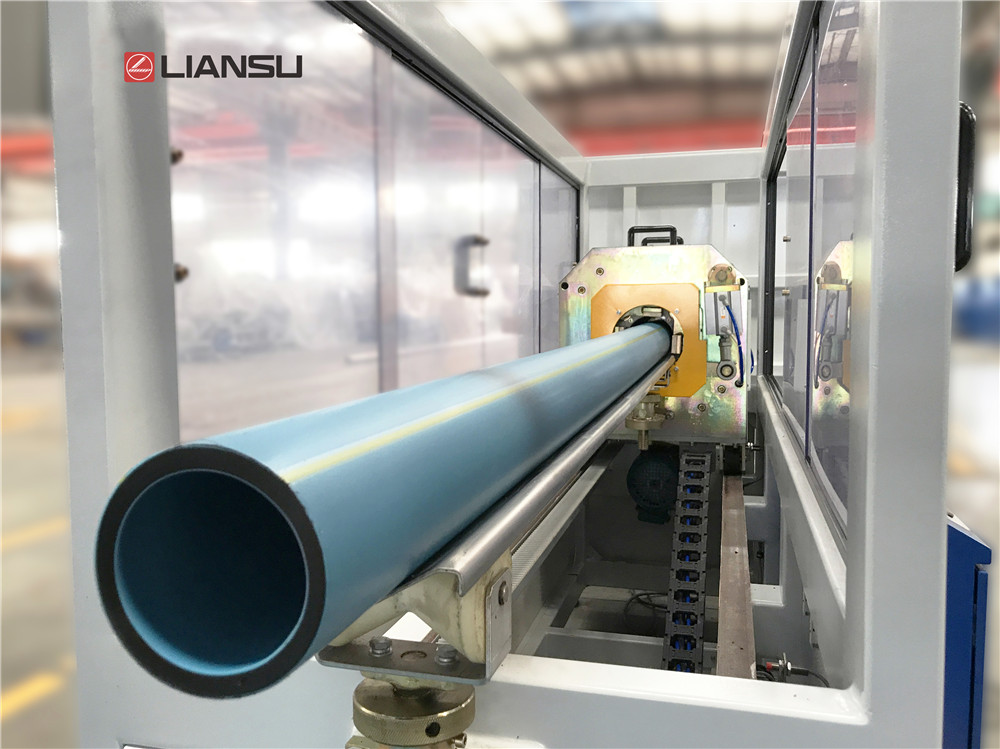

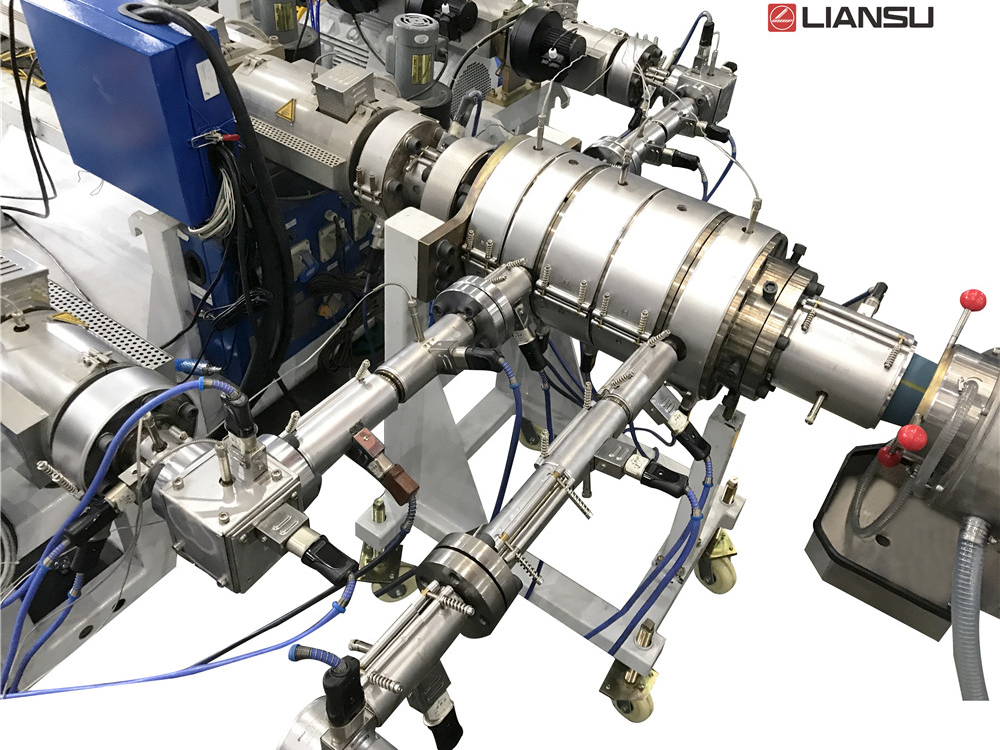

- The die body adopts independent spiral mechanism of each layer to ensure the uniformity, and the exhaust mechanism ensures the stable melt temperature under high production and reduces the cooling length.

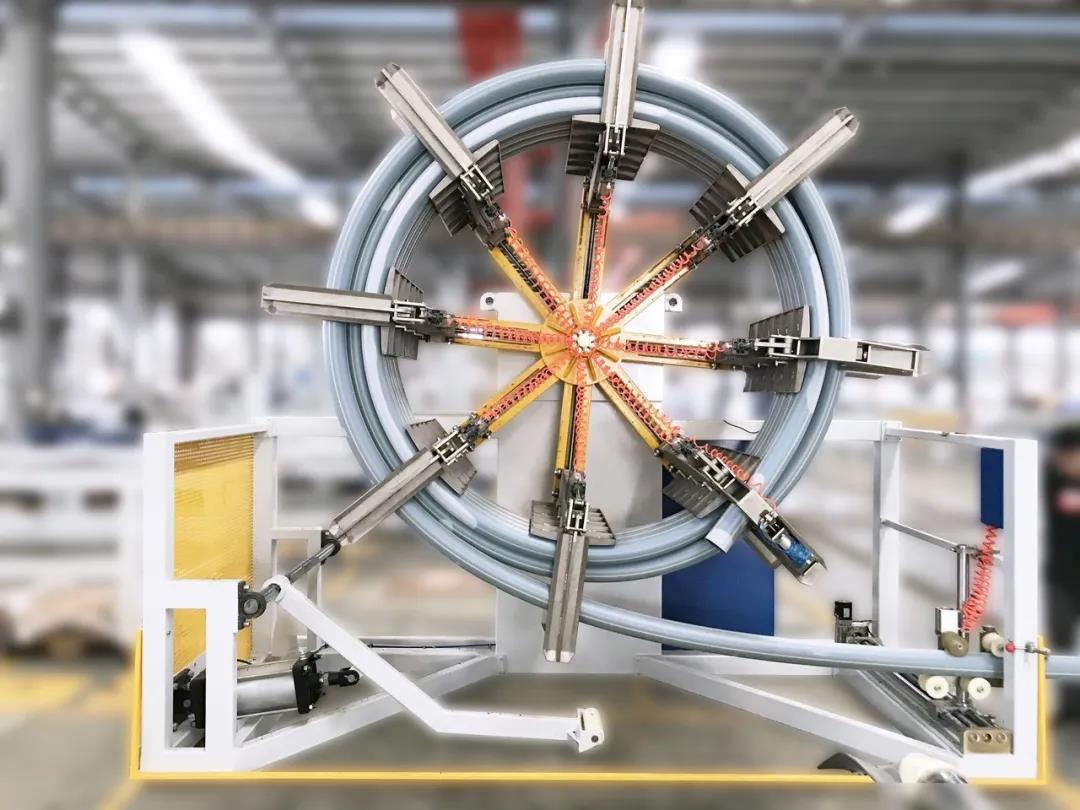

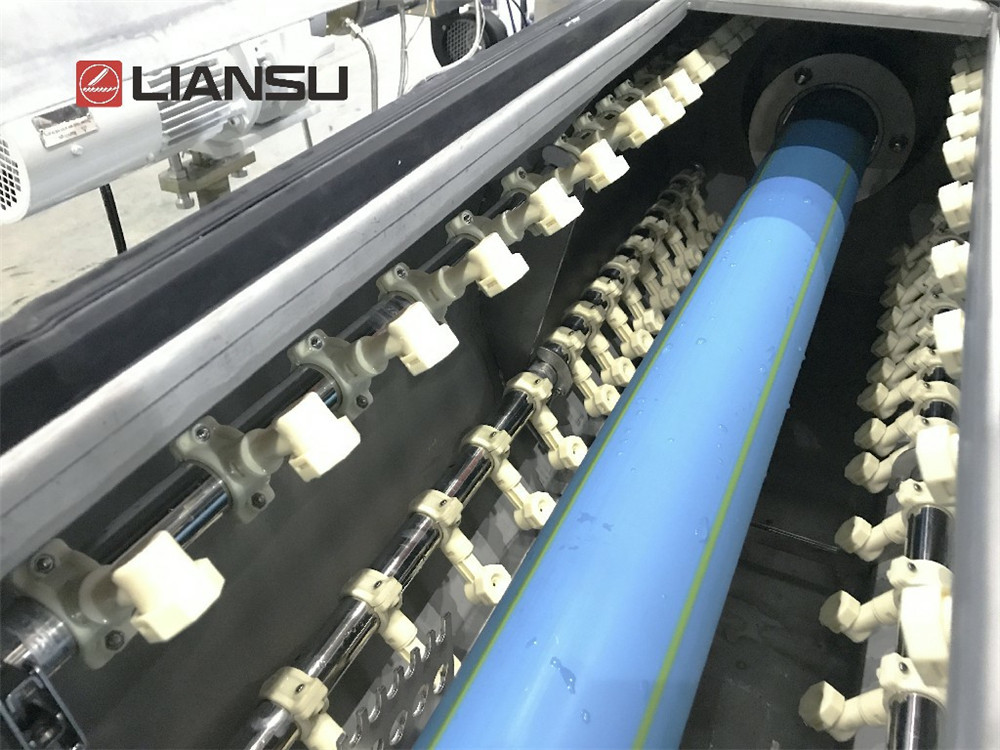

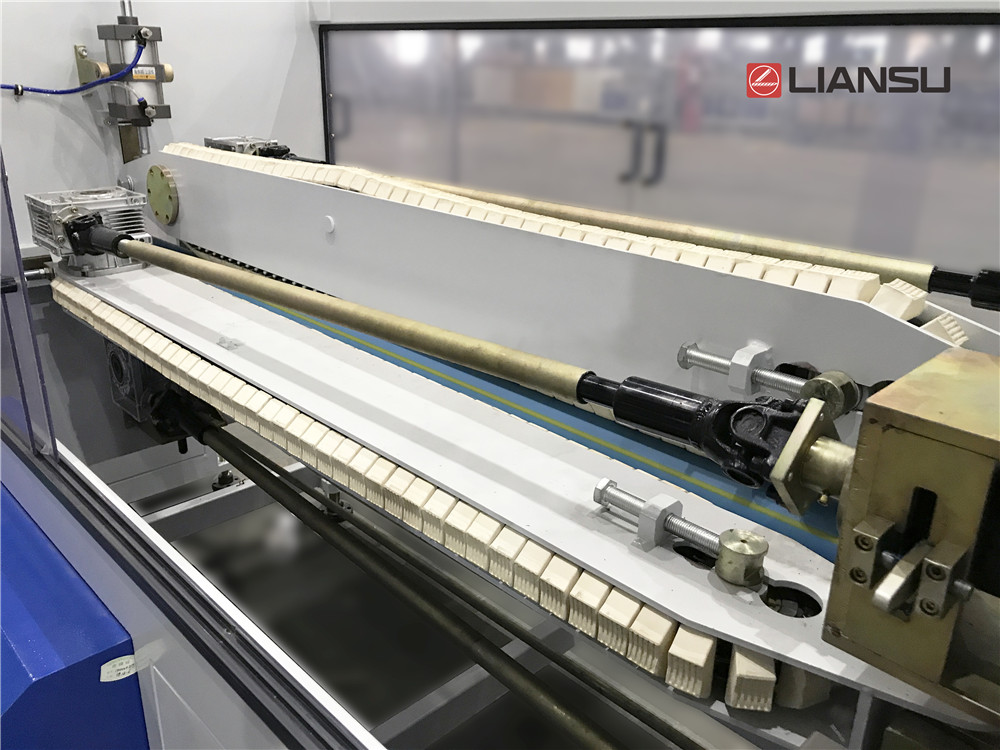

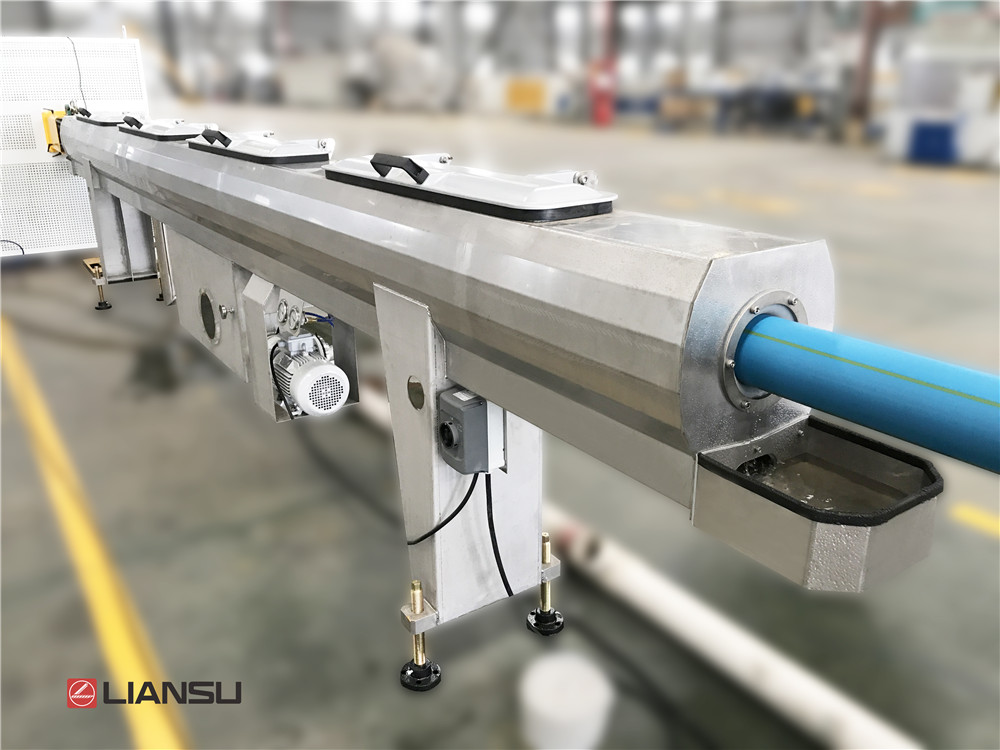

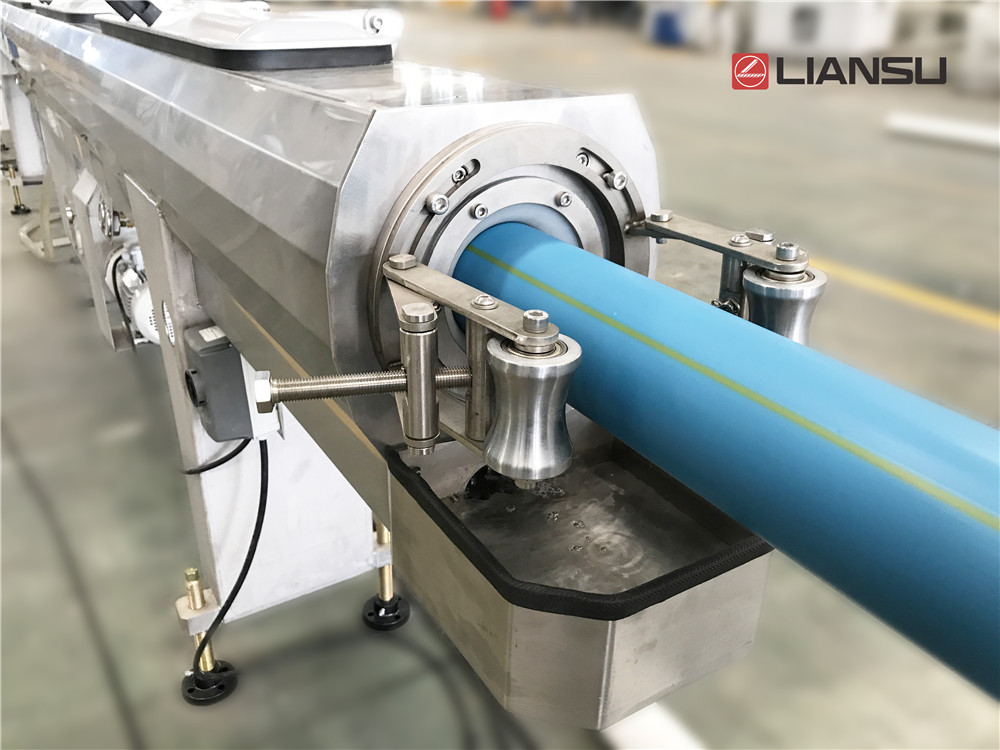

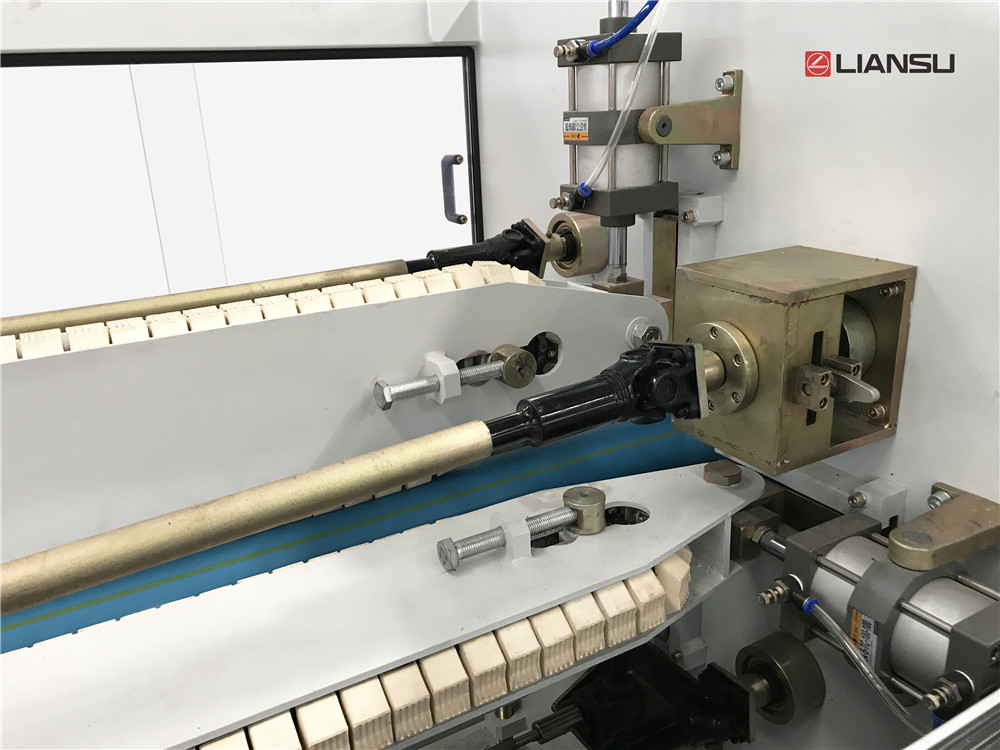

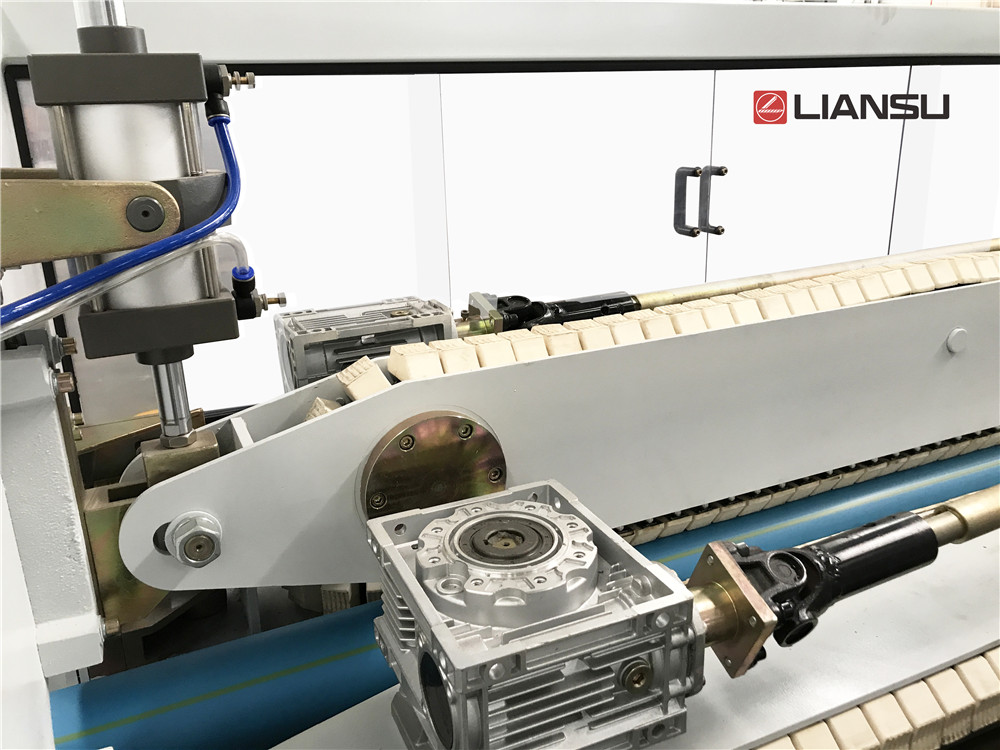

- The hauling adopts servo control to ensure stable production in large speed range.

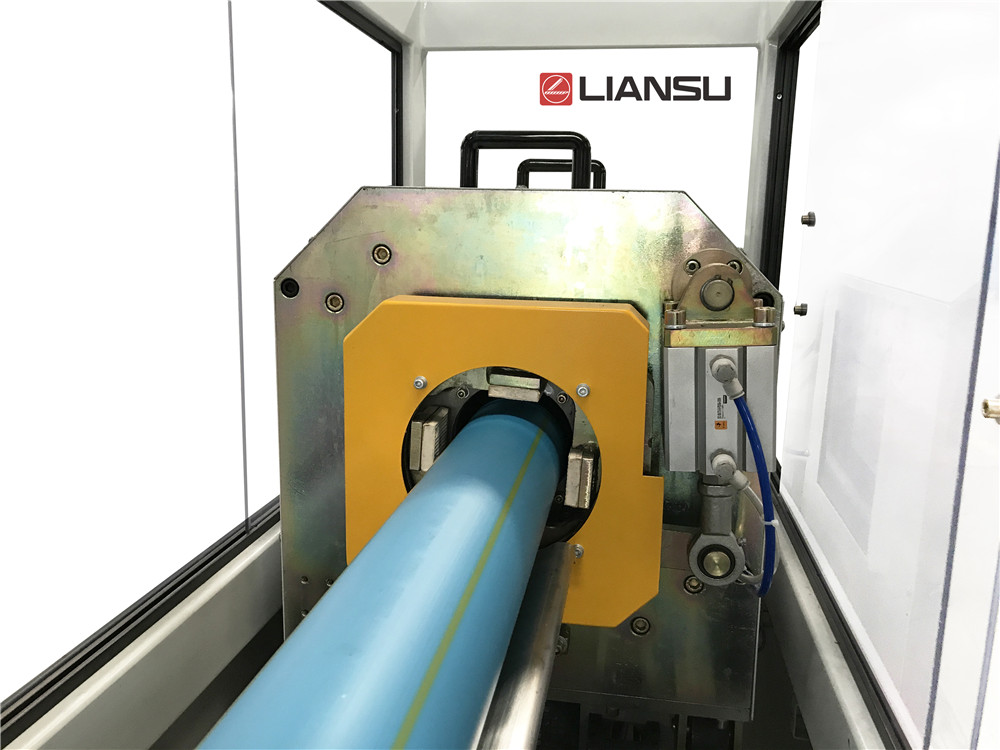

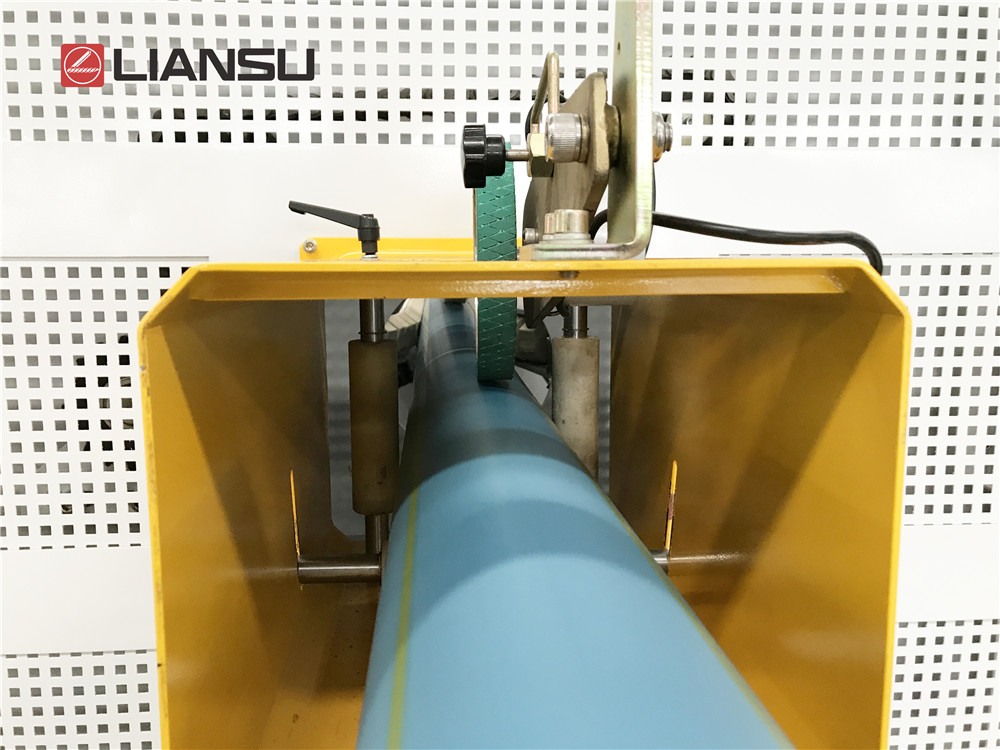

- Adopt swarfless cutting mechanism, clear and accurate fixed length, beautiful incision.

- Production data acquisition and analysis system can be selected to realize transparent production management.

-

- Model

- Diameter, mm

- Output, kg/h

- Speed, m/min

- Co-Extrusion

- LSP-63PE

- Ø16-Ø63

- 300

- 25

- 1 - 3 Layer

- LSP-110PE

- Ø20-Ø110

- 300

- 14

- 1 - 3 Layer

- LSP-160PE

- Ø40-Ø160

- 600

- 8

- 1 - 3 Layer

- LSP-250PE

- Ø50-Ø250

- 600

- 6.5

- 1 - 3 Layer

* Test and accept based on Liansu standard formula

- Model

- Diameter, mm

- Output, kg/h

- Hauling Speed, m/min

- Co-Extrusion

- LSP-63PE

- Ø16-Ø63

- 300

- 25

- 1 - 3 Layer

- LSP-110PE

- Ø20-Ø110

- 300

- 14

- 1 - 3 Layer

- LSP-160PE

- Ø40-Ø160

- 600

- 8

- 1 - 3 Layer

- LSP-250PE

- Ø50-Ø250

- 600

- 6.5

- 1 - 3 Layer

* Test and accept based on Liansu standard formula

-

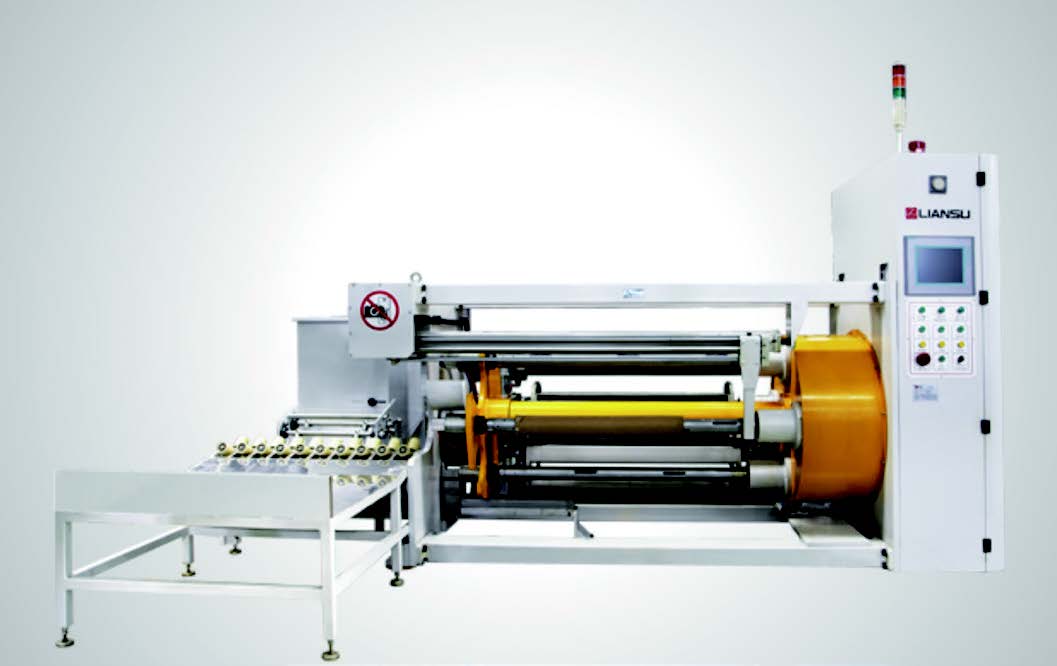

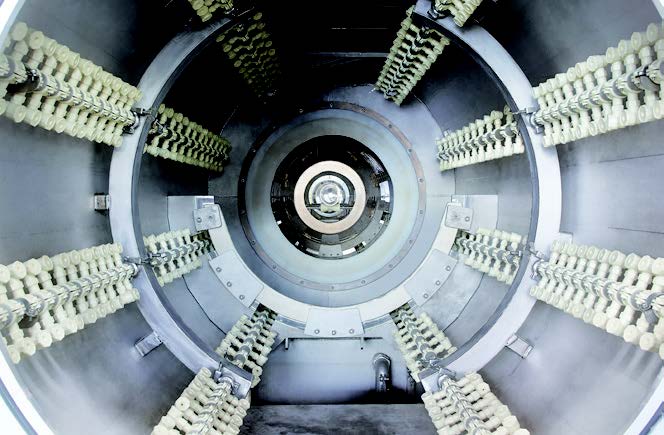

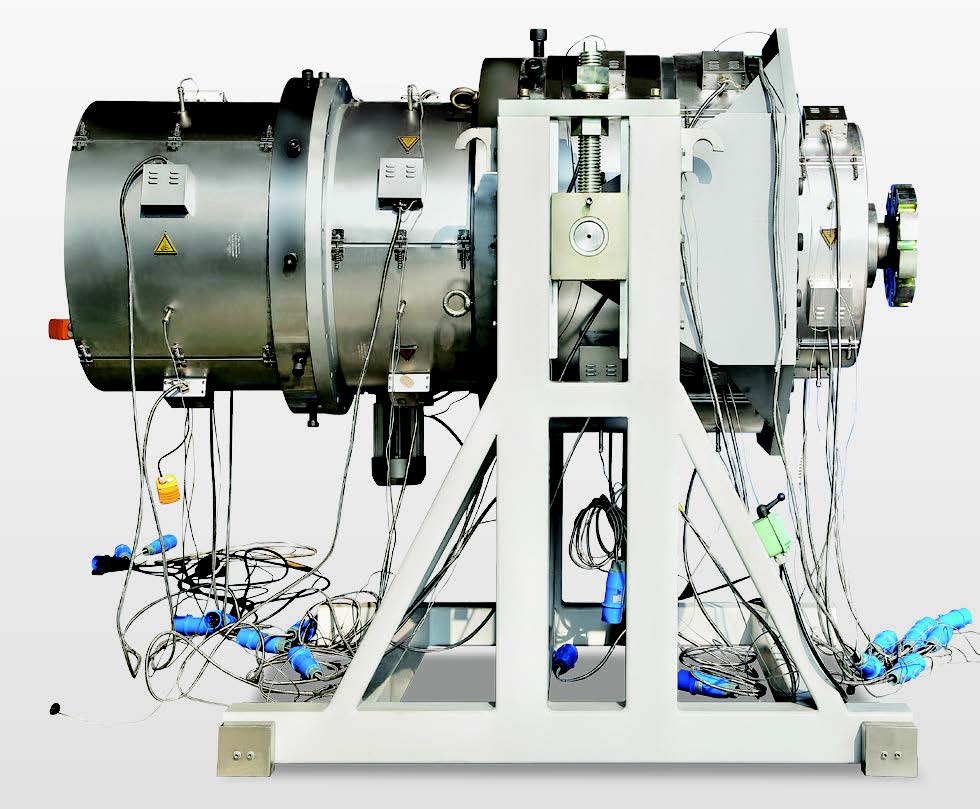

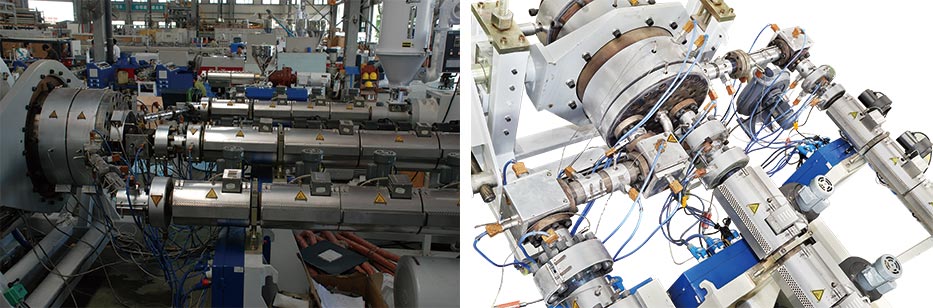

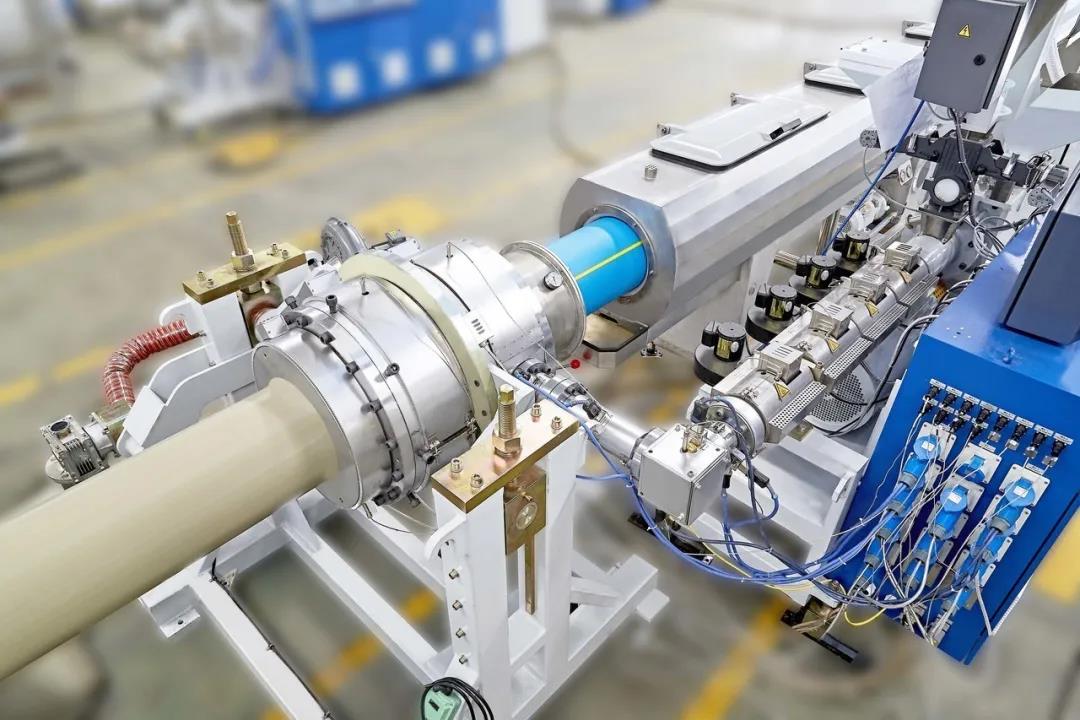

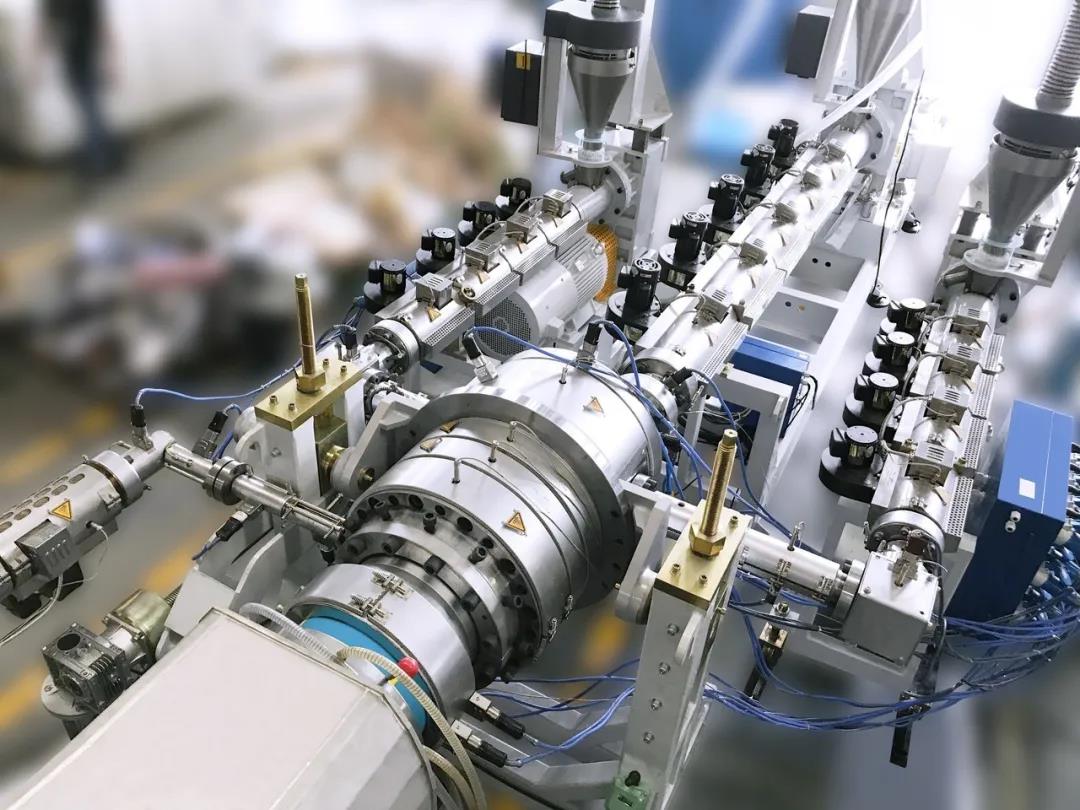

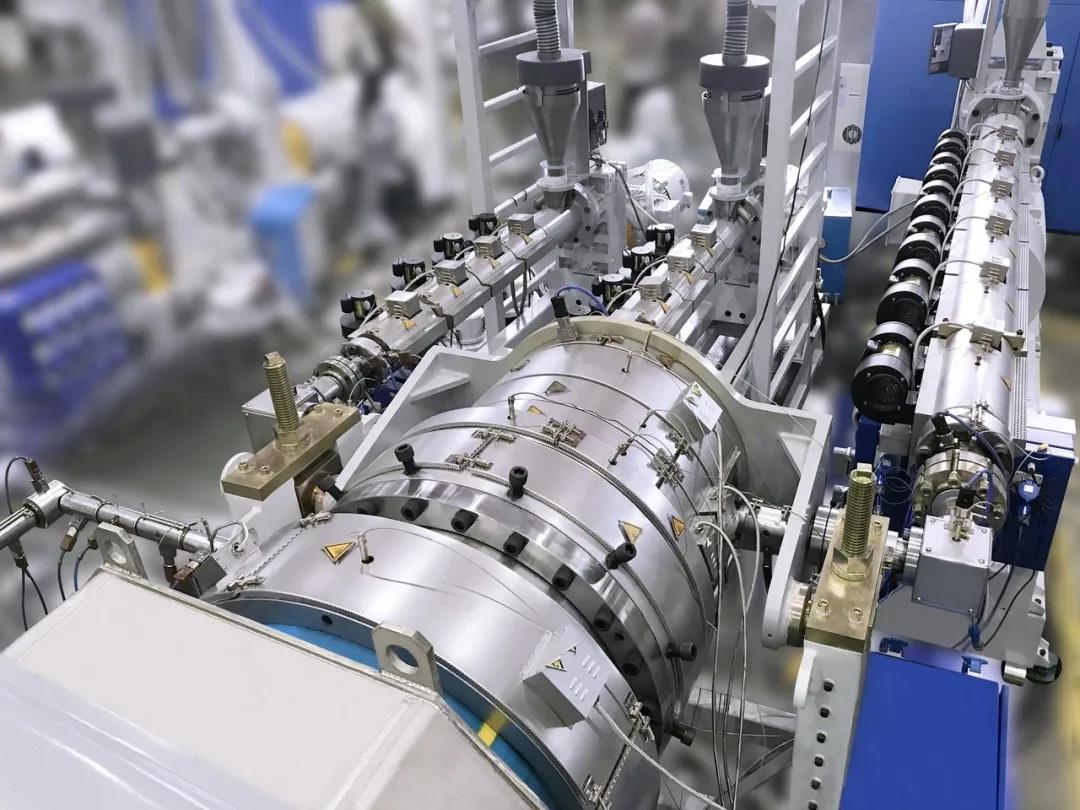

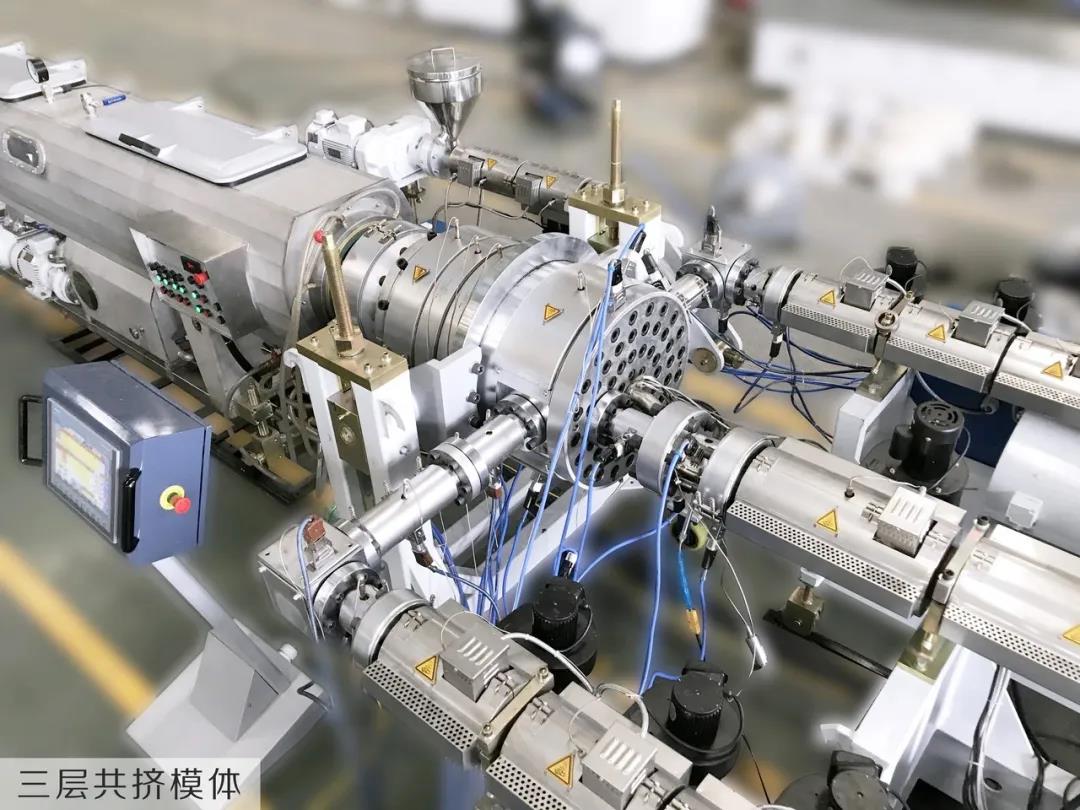

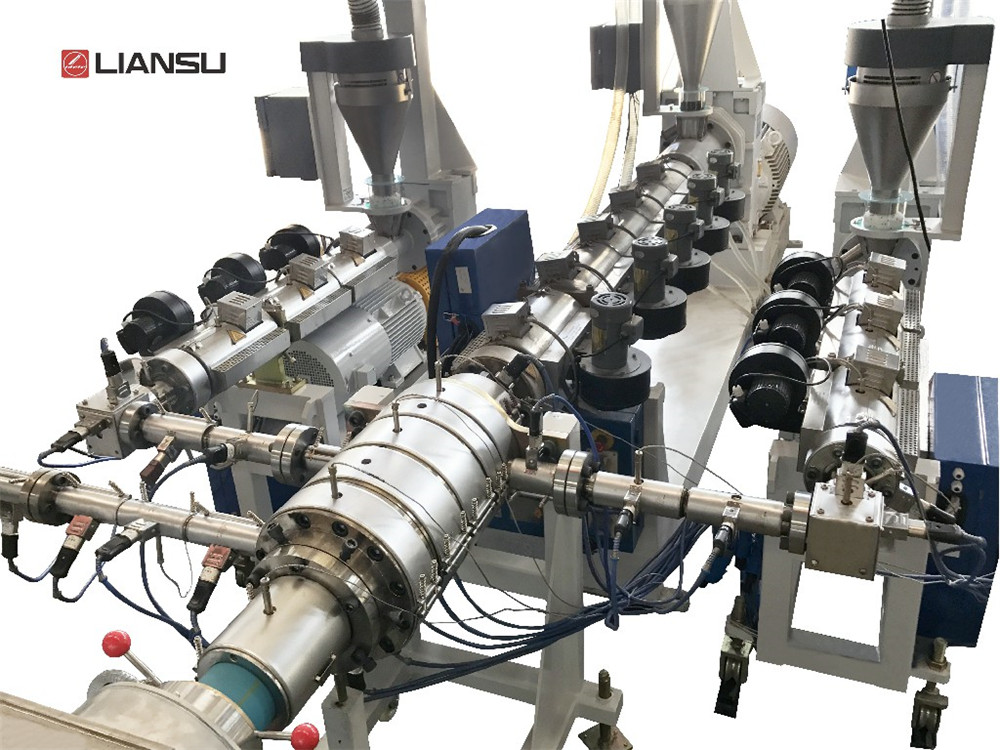

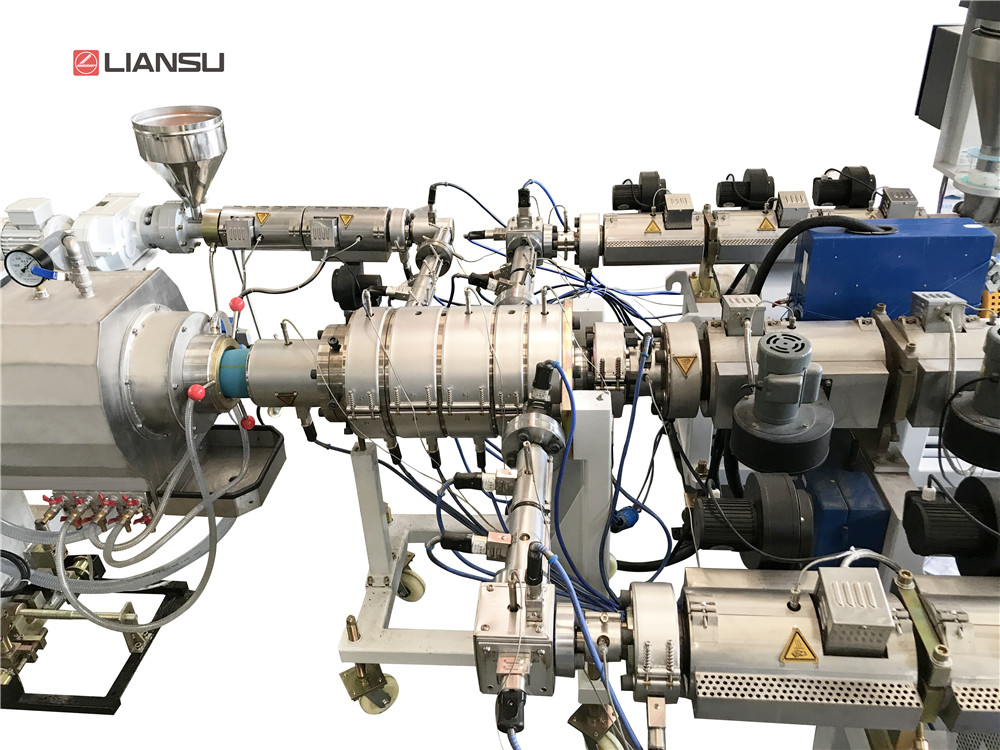

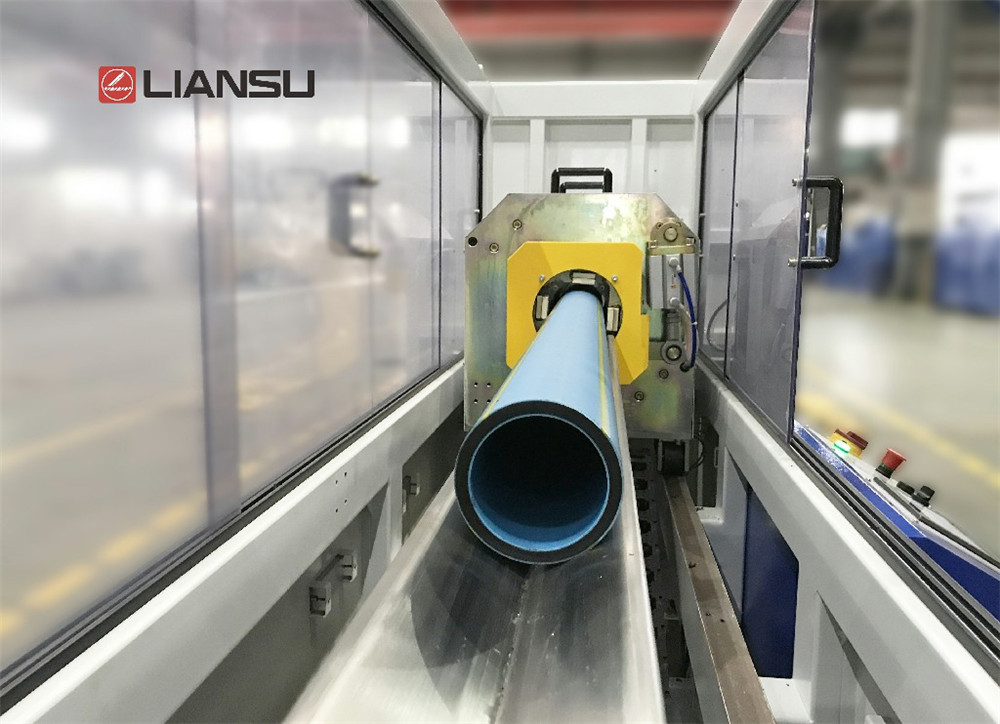

EXTRUDER

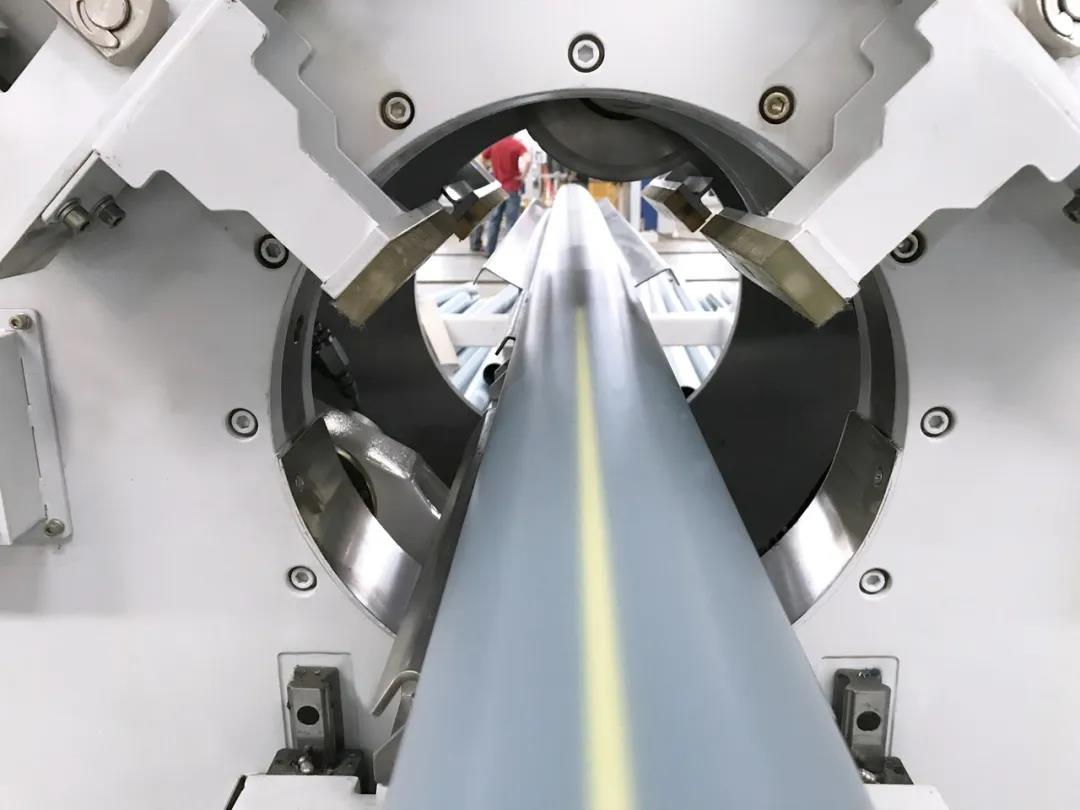

- Design with multiple spiral head, easy adjusting of the wall thickness.

- Different layer materials, multi-group extruding.

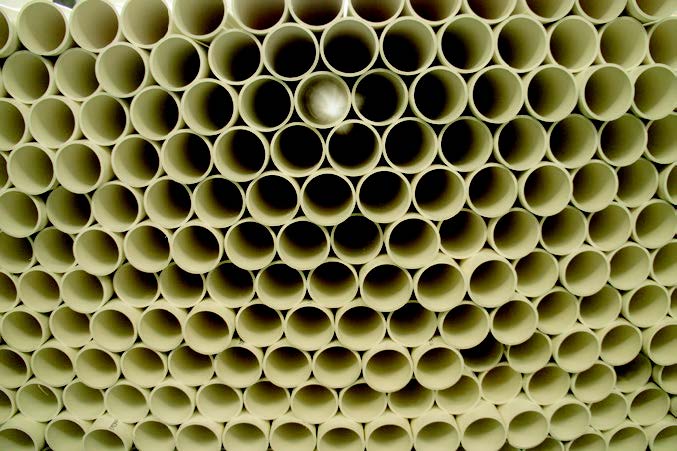

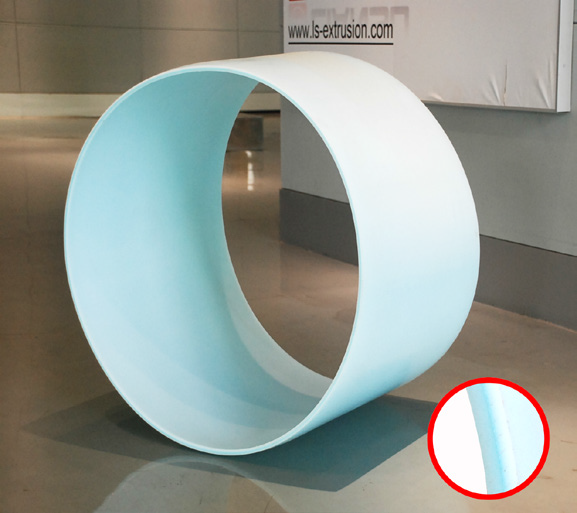

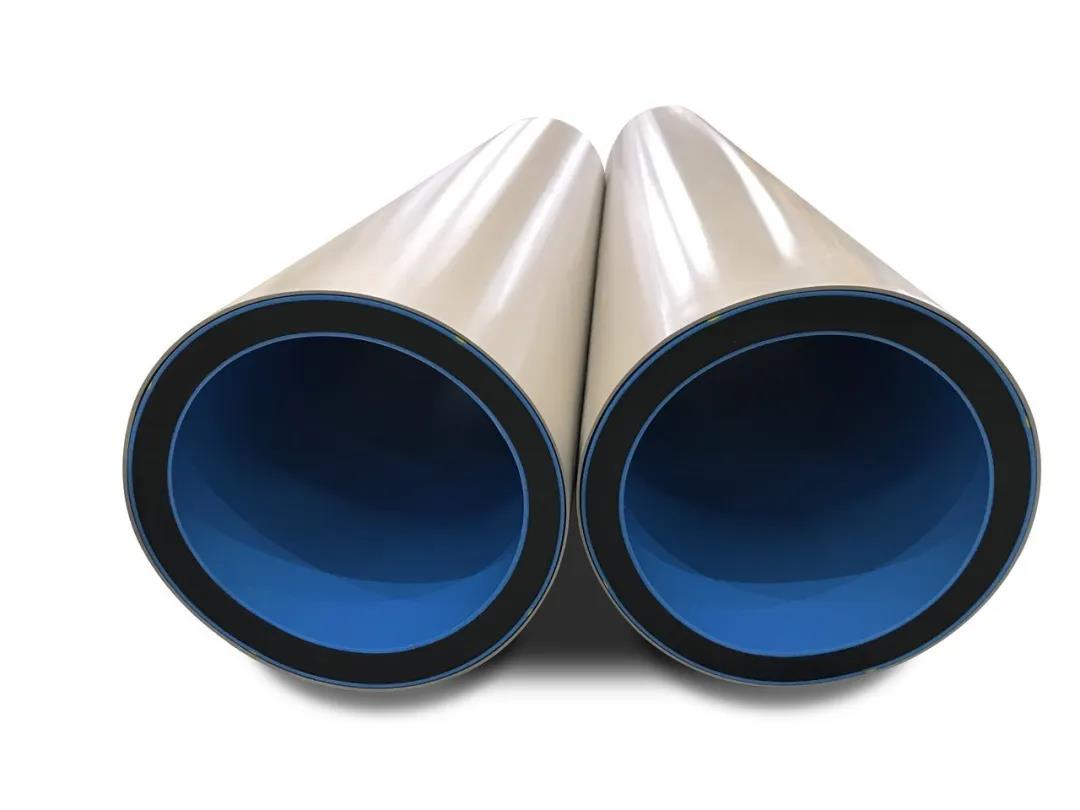

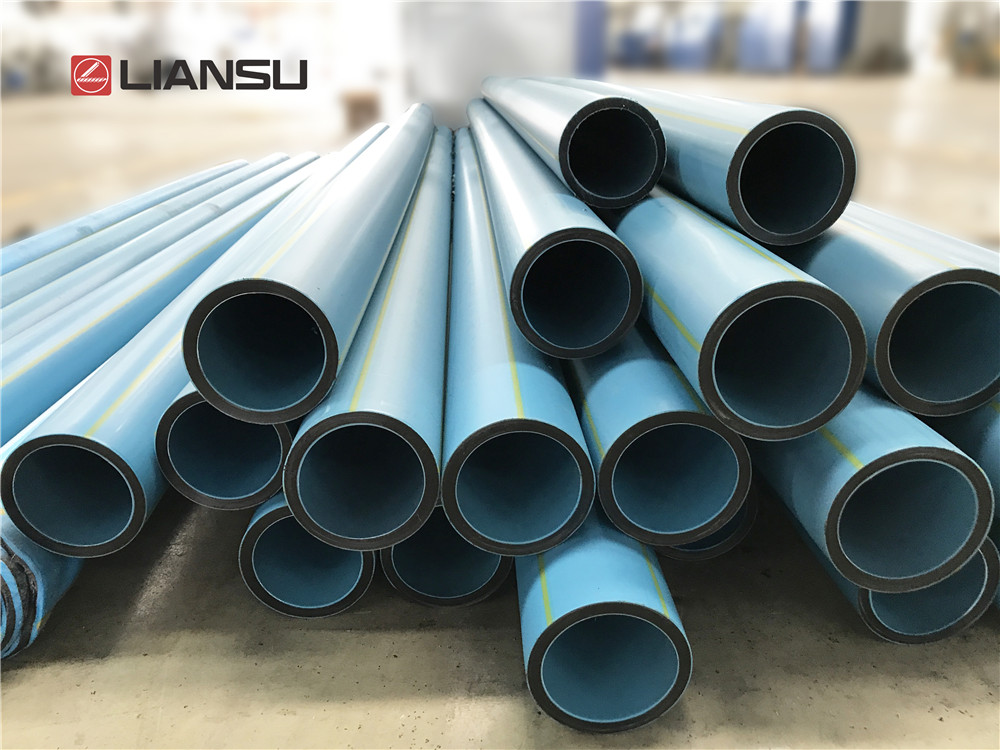

SAMPLE

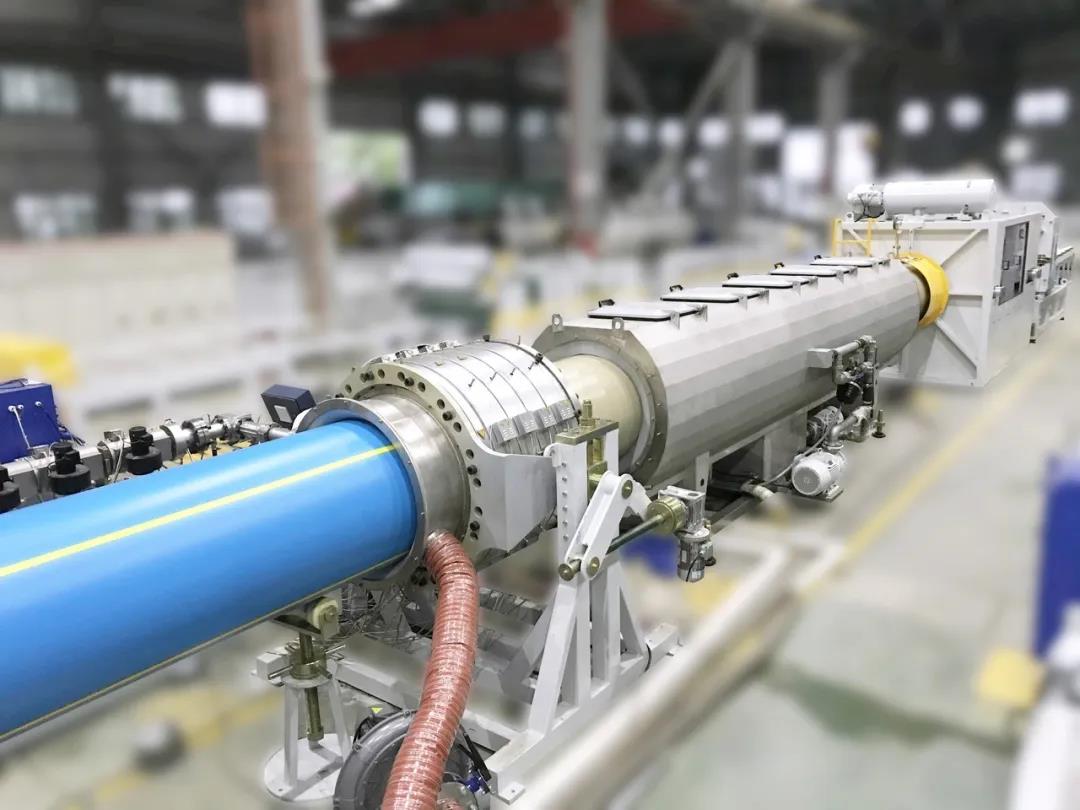

Three-layer HDPE co-extruding pipe Five-layer PERT thermal insulating pipe

-

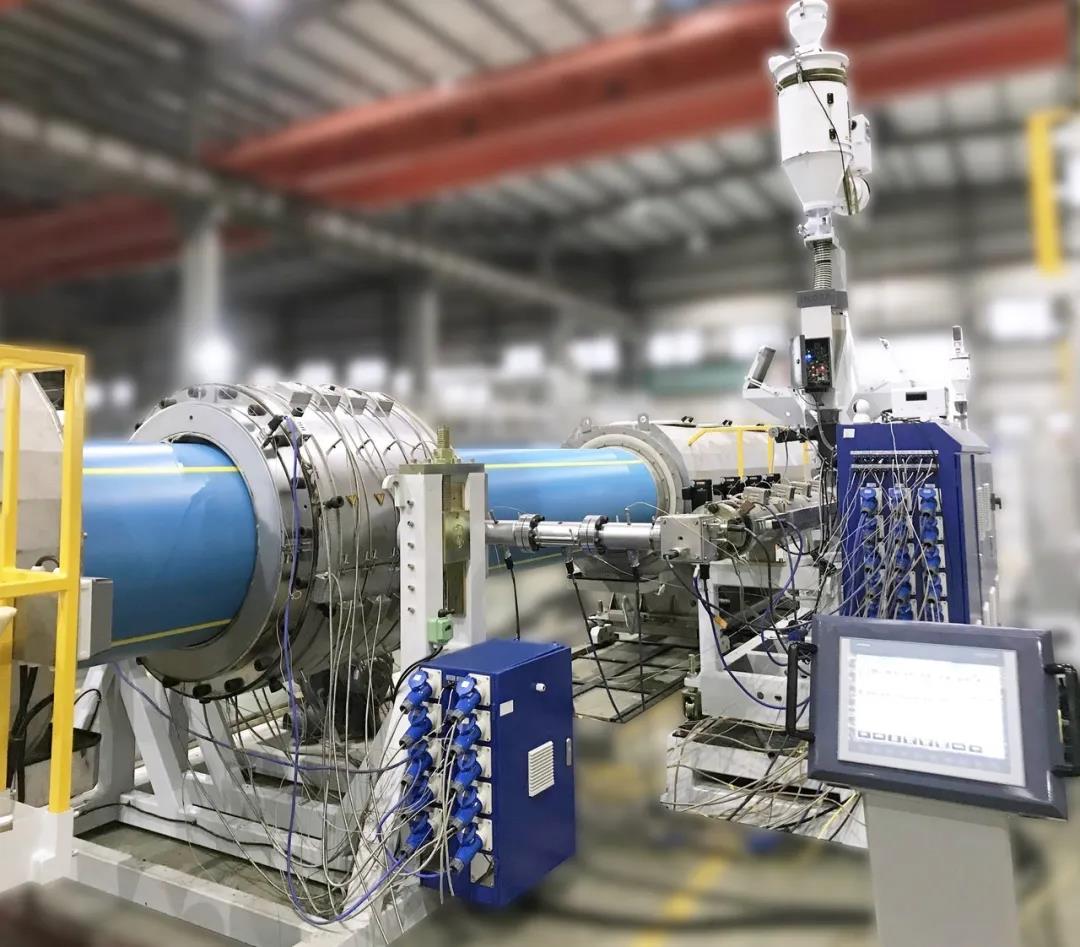

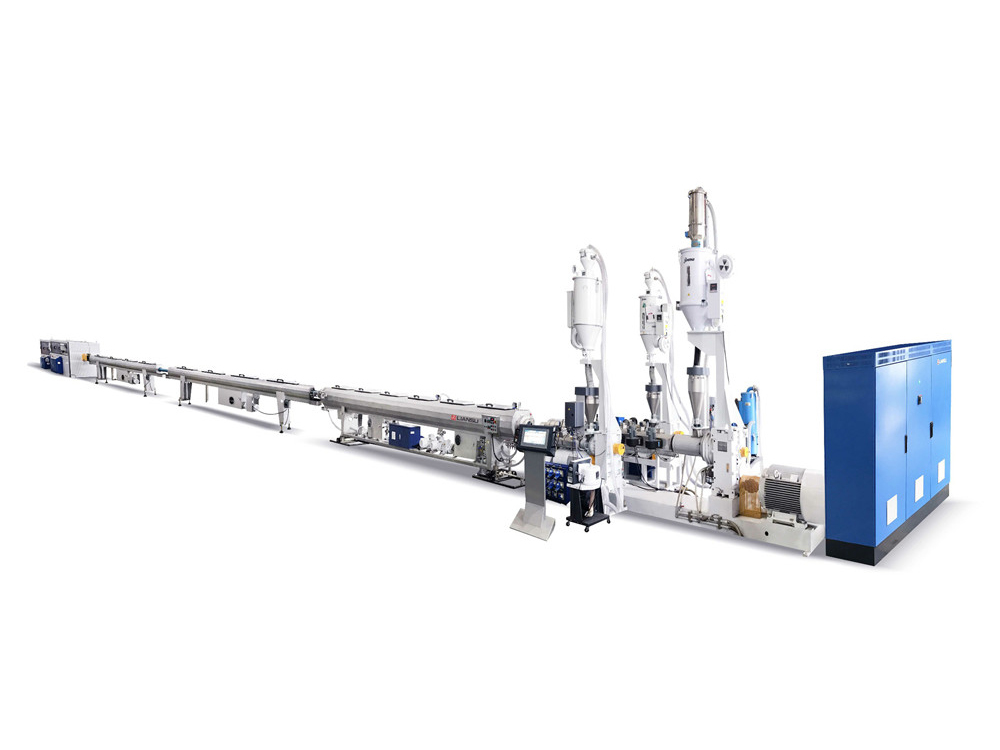

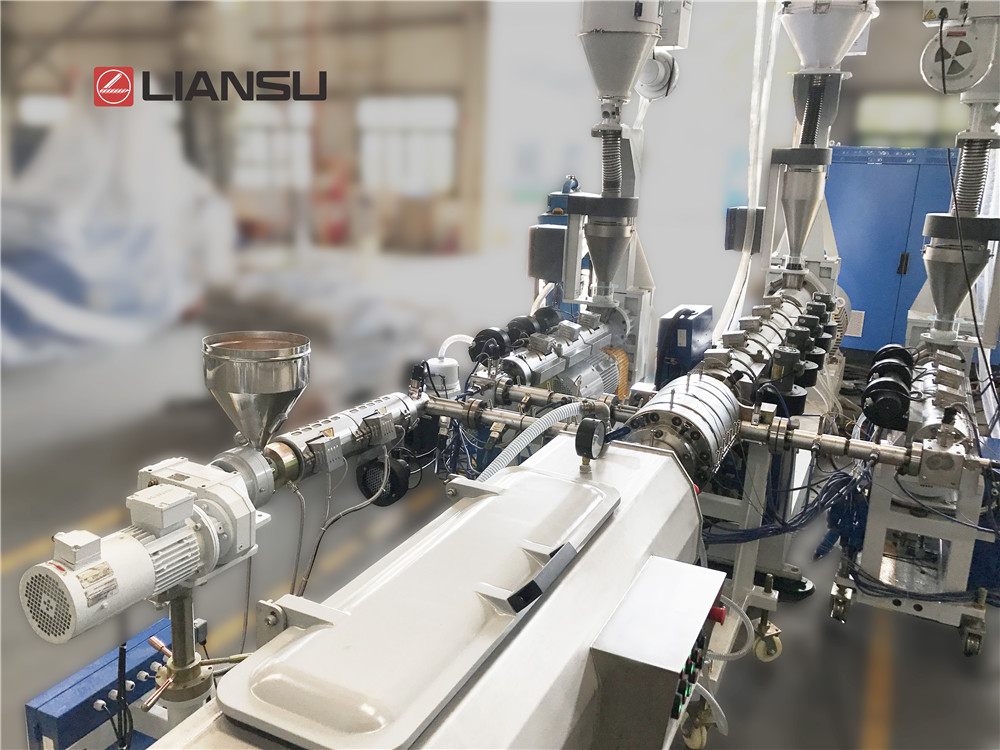

20-315mm HDPE Multi-Layer Pipe Production Line

f13700222f9fd69f18c60833bf11638d7bf6e0586242eee67535191e8089041e8956aca313aa566650c7321ee3a987b5eb66f4daff2ec09616fa7d083f31392a4516ed990f0fe709b6046105308736d2c03c111405f1ad315d6de42e71c86a352c90dbd9606a99cb5701fc9386e8b519c8ba64b0c1faf85ed8f501b5dc53c56693ae0b682bcf4724abc5310a4f24114f3d42f9bb97f84c97a68f5fc994f918c472c2a5835f593c936d6016fece05c0b1e42566a798bf4996d0f60b24bfb77076c235b6c79313923b5040dabc143960b42a861f0301864e279c8ee20735ec50a58ef3f13596d8dc5cb8353488e014ebc4a671825116291734e903965593ba0a8f6f4d180af5646a5094c7cbfb25f4f564f4cc31a8b1528109dea716f63fe9996c2ae5c28146f1b20497e7f23da895960fd0cf57c2c79a609959aef57d2ee451924fafe17ce9ff9973b873f08b3d99244b985a8227d9d7056c6ecf51148a3ec954.jpeg

f13700222f9fd69f18c60833bf11638d7bf6e0586242eee67535191e8089041e8956aca313aa566650c7321ee3a987b5eb66f4daff2ec09616fa7d083f31392a4516ed990f0fe709b6046105308736d2c03c111405f1ad315d6de42e71c86a352c90dbd9606a99cb5701fc9386e8b519c8ba64b0c1faf85ed8f501b5dc53c56693ae0b682bcf4724abc5310a4f24114f3d42f9bb97f84c97a68f5fc994f918c472c2a5835f593c936d6016fece05c0b1e42566a798bf4996d0f60b24bfb77076c235b6c79313923b5040dabc143960b42a861f0301864e279c8ee20735ec50a58ef3f13596d8dc5cb8353488e014ebc4a671825116291734e903965593ba0a8f6f4d180af5646a5094c7cbfb25f4f564f4cc31a8b1528109dea716f63fe9996c2ae5c28146f1b20497e7f23da895960fd0cf57c2c79a609959aef57d2ee451924fafe17ce9ff9973b873f08b3d99244b985a8227d9d7056c6ecf51148a3ec954.jpeg3 Layer Coextrusion HDPE Pressure Pipe Line

c0e125267ad65caa37ceb3fe36966d30b66344f80c0612251688f5be232925a1d39e88fe4ff5b44479485b8dedccdddaa3a0ebabef8dfa84571dfc88272d4671d86f552cae4519b81df819bf831e06446f881f281a6bfdfc559b9729352f44bf40afdb3e9a02a5203bd22c5811b4693fd67af8ec146f46565a47656e8d606fb8265259c63a7bb41b94ecccd724684063afea72f34b6ba42a8a153aaaab791a53f50bdb4b261e765802e59c3c3ef2cf4ba10f70c1ca9ea079153f51367a79fb56ed9728e28ff0eb98402940ac4283b97afa7939cdf8096e2340222c4065f887393ddfc9dc9a493cade7c9f90abf0a44555326a7f59d94a04d001474c66f5c19d5e664cf69bc46bfef239f86e3ffcbef50c605239bfdd1027b8c2b00defa164cdeb242742e09cadf9ff1861c749f13af65e16081e343d278106796efa17d19c8403f5b0d791a0750ec0dbc7efde7d586d31bd025d79a10f29e5e18aa3ebeec6b8f7d05fc5df9859a45b0a71c03200cd2936a3de7633d315a3282db7713ae3bf575753628e4894eff9a85e52ee10466e535c558b275c78bcc46f432568b1f15e8457985f21f98b054d93e94c85e7e35a40bf684ee2e78e98161d9e4081a1ded6dfa

c0e125267ad65caa37ceb3fe36966d30b66344f80c0612251688f5be232925a1d39e88fe4ff5b44479485b8dedccdddaa3a0ebabef8dfa84571dfc88272d4671d86f552cae4519b81df819bf831e06446f881f281a6bfdfc559b9729352f44bf40afdb3e9a02a5203bd22c5811b4693fd67af8ec146f46565a47656e8d606fb8265259c63a7bb41b94ecccd724684063afea72f34b6ba42a8a153aaaab791a53f50bdb4b261e765802e59c3c3ef2cf4ba10f70c1ca9ea079153f51367a79fb56ed9728e28ff0eb98402940ac4283b97afa7939cdf8096e2340222c4065f887393ddfc9dc9a493cade7c9f90abf0a44555326a7f59d94a04d001474c66f5c19d5e664cf69bc46bfef239f86e3ffcbef50c605239bfdd1027b8c2b00defa164cdeb242742e09cadf9ff1861c749f13af65e16081e343d278106796efa17d19c8403f5b0d791a0750ec0dbc7efde7d586d31bd025d79a10f29e5e18aa3ebeec6b8f7d05fc5df9859a45b0a71c03200cd2936a3de7633d315a3282db7713ae3bf575753628e4894eff9a85e52ee10466e535c558b275c78bcc46f432568b1f15e8457985f21f98b054d93e94c85e7e35a40bf684ee2e78e98161d9e4081a1ded6dfa

Subscribe to our channel

Subscribe to our channel

Subscribe to our channel

Subscribe to our channel

Subscribe to our channel

© Liansu 2024,