-

-

- Model

- PIPE RANGE (mm)

- MAX OUTPUT (kg/h)

- HAULING SPEED (m/min)

- INSTALLED POWER (kw)

- LINE LENGTH (m)

- LSP-32

- Ø16-Ø32

- 200

- 40

- 75

- 46

-

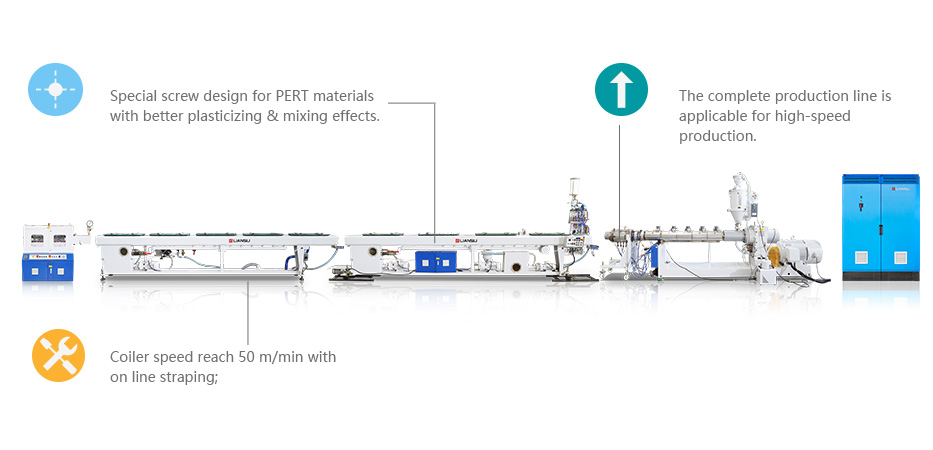

PERT Muti Layer Pipe Production Line

Ø16-Ø32 mm

Pipe Range

40 m/min

Max Hauling Speed

75 kw

Total Installed Power

350 kg/h

Max Output

PERT Muti Layer Pipe Production Line

Ø16-Ø32

PIPE RANGE(mm)

40 m/min

Max Hauling Speed

75 kw

Total Installed Power

350 kg/h

Max Output

The extruder adopts large L/D ratio screw and special permanent magnet synchronous servo motor for extruder to realize high production and energy saving.

The die body adopts independent spiral mechanism of each layer to ensure the uniformity, and the exhaust mechanism ensures the stable melt temperature under high production and reduces the cooling length.

The hauling adopts servo control to ensure stable production in large speed range.

Equipped with online straight pipe, coil automatic packing mechanism, efficient and labour saving.

Production data acquisition and analysis system can be selected to realize transparent production management.

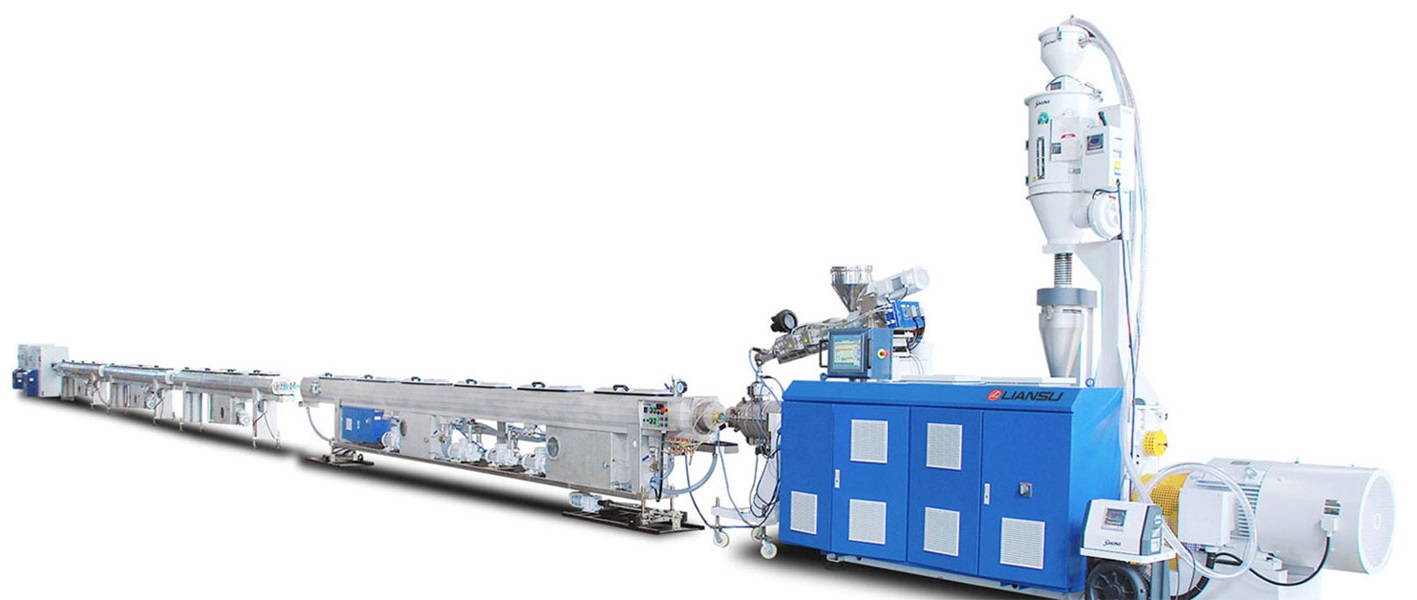

The extruder adopts large L/D ratio screw and special permanent magnet synchronous servo motor for extruder to realize high production and energy saving.

The die body adopts independent spiral mechanism of each layer to ensure the uniformity, and the exhaust mechanism ensures the stable melt temperature under high production and reduces the cooling length.

The hauling adopts servo control to ensure stable production in large speed range.

Equipped with online straight pipe, coil automatic packing mechanism, efficient and labour saving.

Production data acquisition and analysis system can be selected to realize transparent production management.

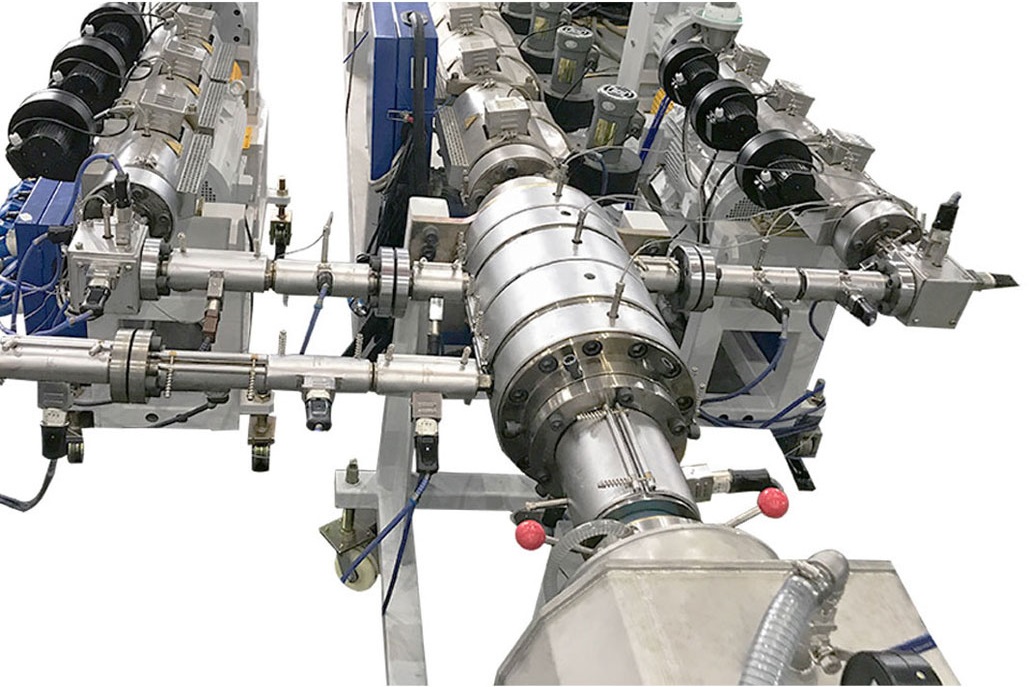

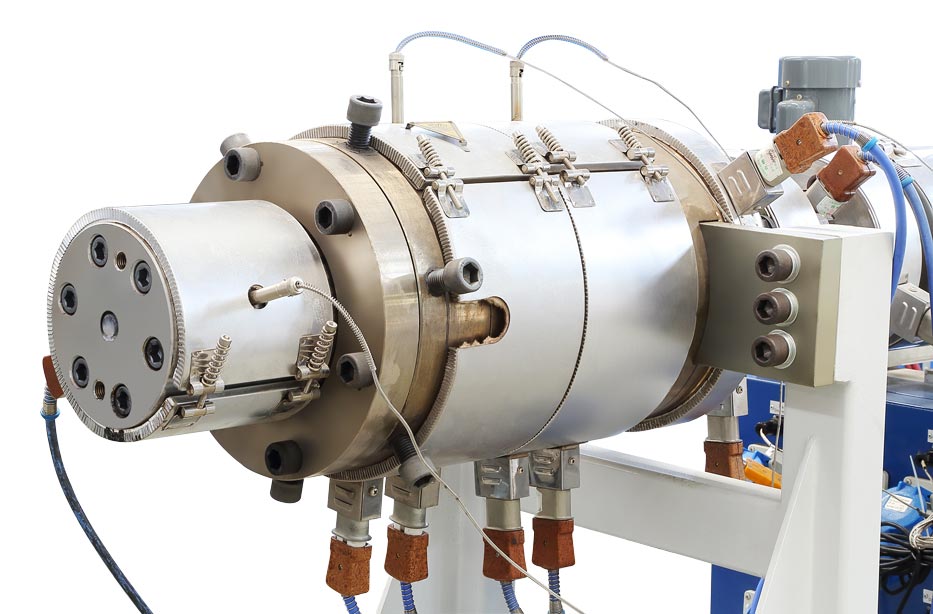

Extruder

The extruder adopts extrusion dedicated permanent magnet synchronous servo motor, which saves space and is suitable for centralized placement of multiple extruder.

Low melt temperature design ensures good plasticizing effect.

PROFINET bus communication control of the whole line can avoid the influence of interference on each extruder, hauling and cutting transmission, and provide convenience for information collection.

Co-extrusion machine installation adopts back structure, saving space.Extruder

The extruder adopts extrusion dedicated permanent magnet synchronous servo motor, which saves space and is suitable for centralized placement of multiple extruder.

Low melt temperature design ensures good plasticizing effect.

PROFINET bus communication control of the whole line can avoid the influence of interference on each extruder, hauling and cutting transmission, and provide convenience for information collection.

Co-extrusion machine installation adopts back structure, saving space.

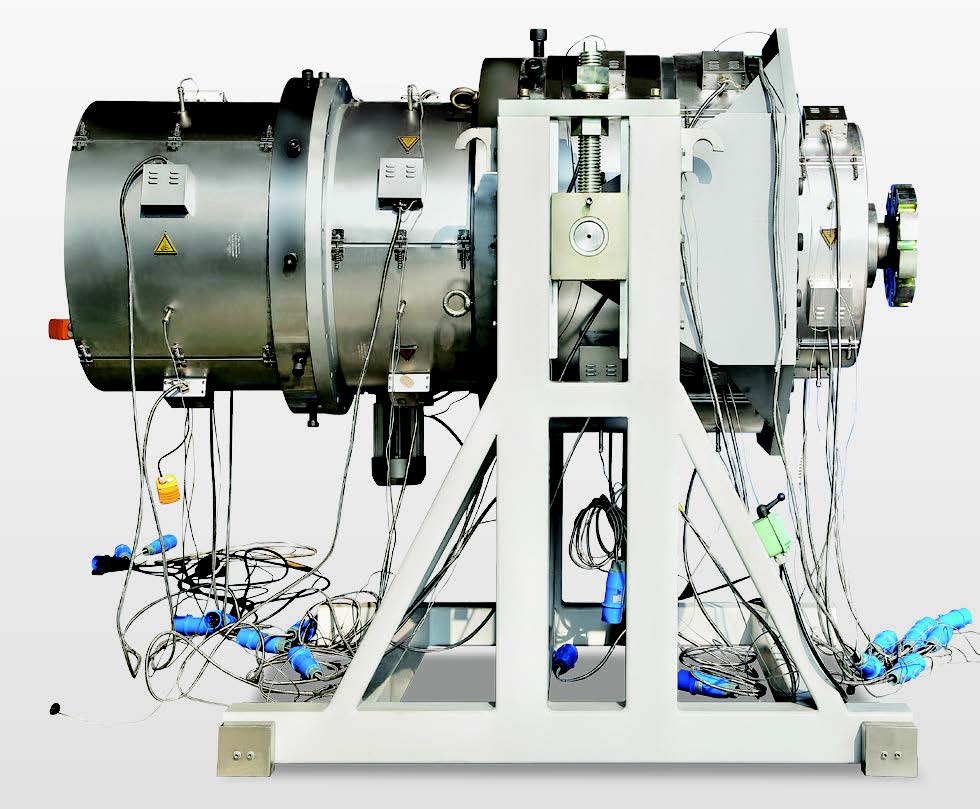

Mould Design

Spiral structure, simple maintenance, accurate thickness of each layer. Sleeve structure is adopted in the setting die, with forced water cooling at the inlet, which ensures high speed and stability.Mould Design

Spiral structure, simple maintenance, accurate thickness of each layer. Sleeve structure is adopted in the setting die, with forced water cooling at the inlet, which ensures high speed and stability.

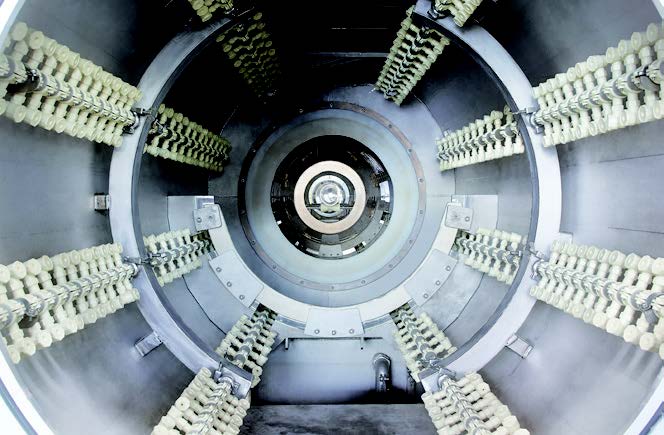

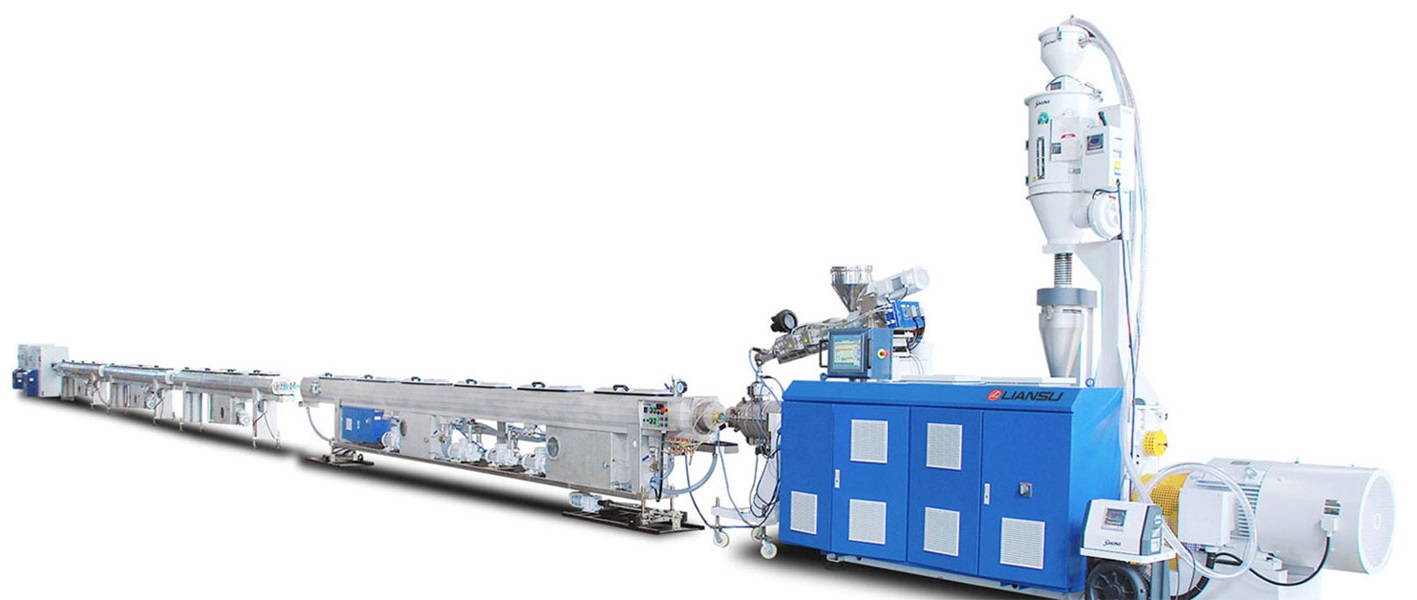

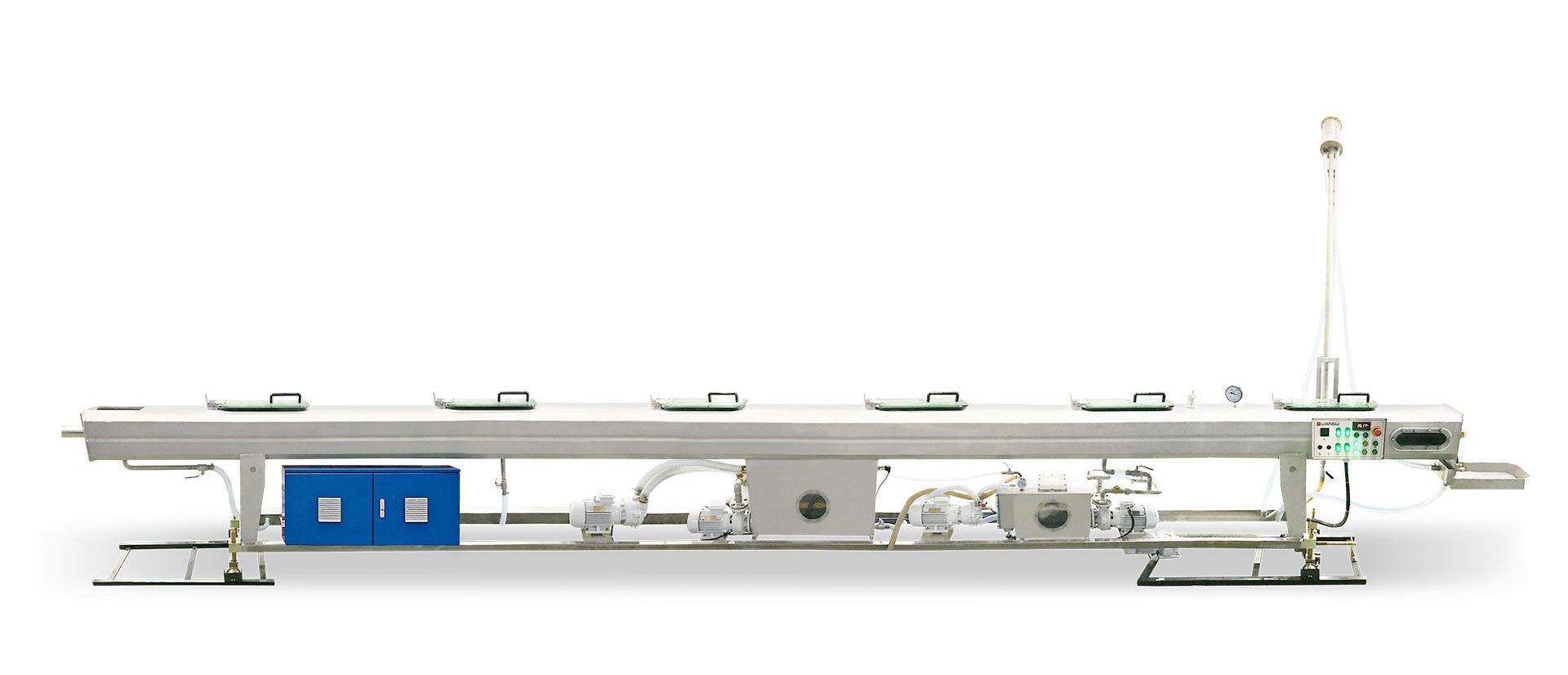

Vacuum Tank

All vacuum of the whole line adopts negative pressure closed-loop automatic adjustment of vacuum degree, stable pressure, improve the quality of pipe production, low noise, energy saving 30 ~ 60%.

Vacuum Tank

All vacuum of the whole line adopts negative pressure closed-loop automatic adjustment of vacuum degree, stable pressure, improve the quality of pipe production, low noise, energy saving 30 ~ 60%.Haul-off Unit

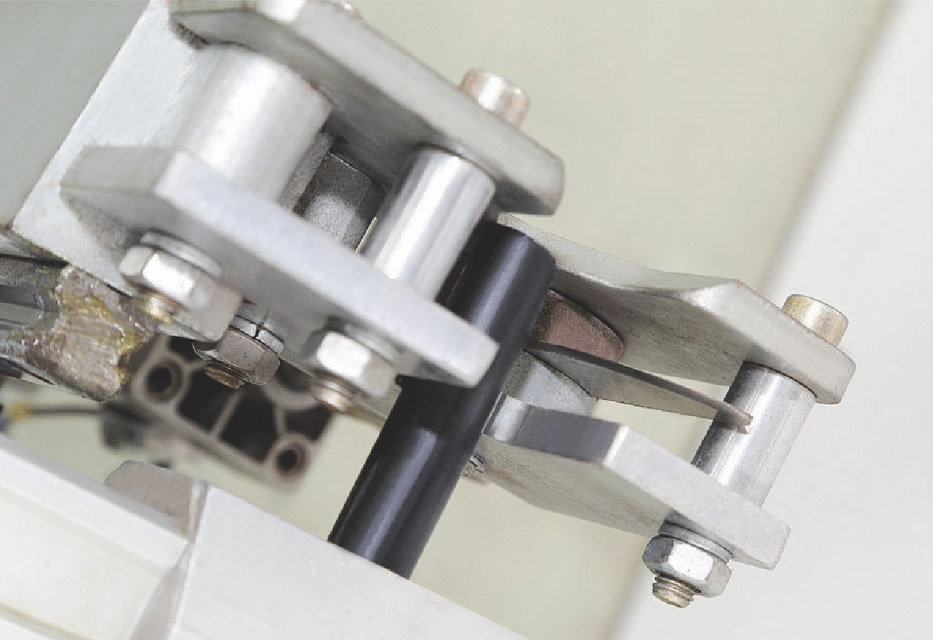

The permanent magnet synchronous motor is adopted in the hauling machine to ensure a stable speed regulation range of more than 50 times, so as to realize the stable hauling of pipe.

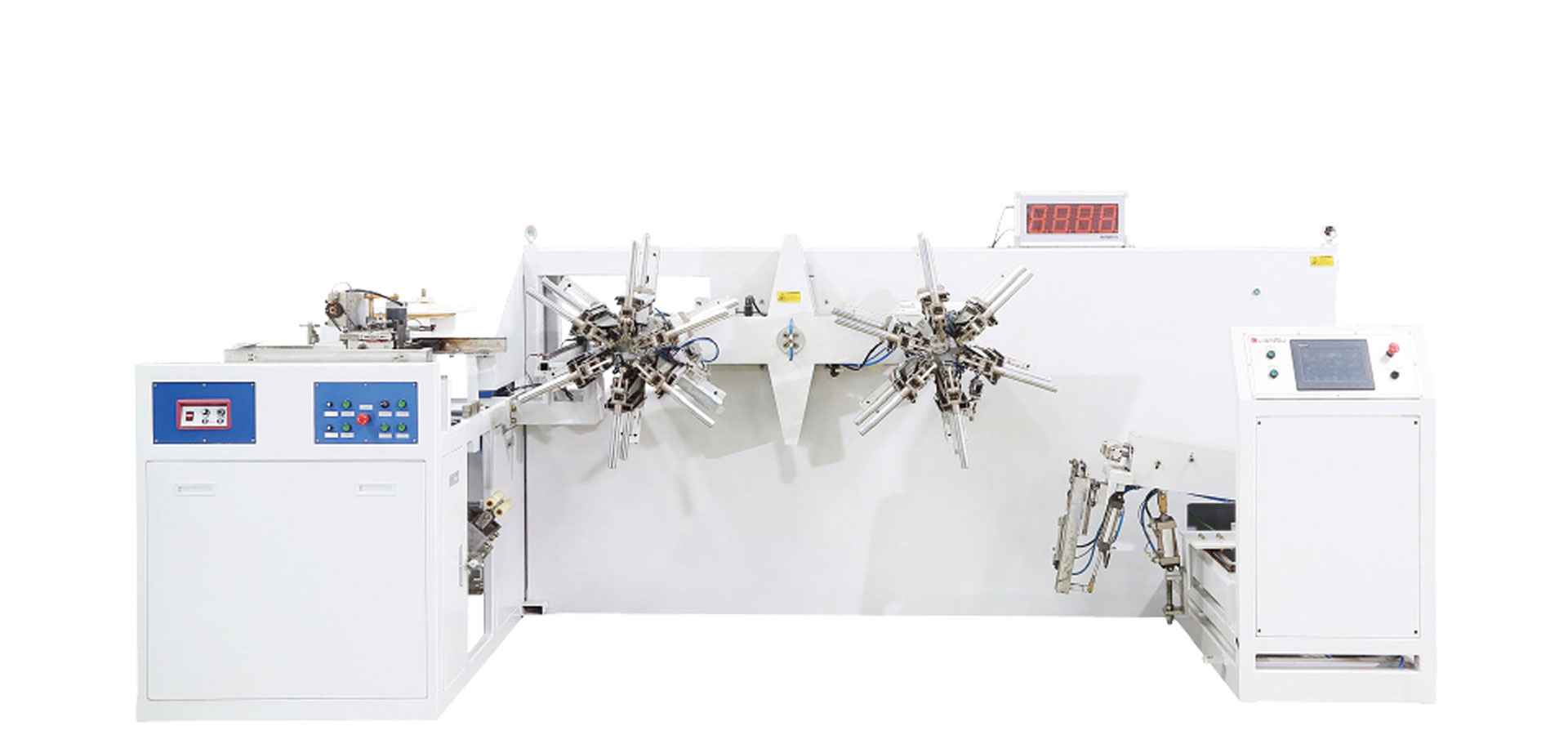

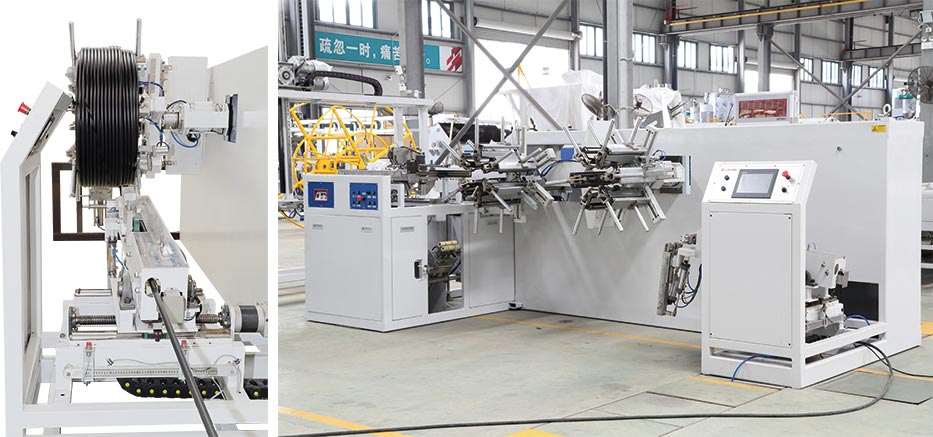

Haul-off Unit

The permanent magnet synchronous motor is adopted in the hauling machine to ensure a stable speed regulation range of more than 50 times, so as to realize the stable hauling of pipe.Winding

Full automatic winding machine integrates automatic packing and pipe unloading, with high degree of automation.

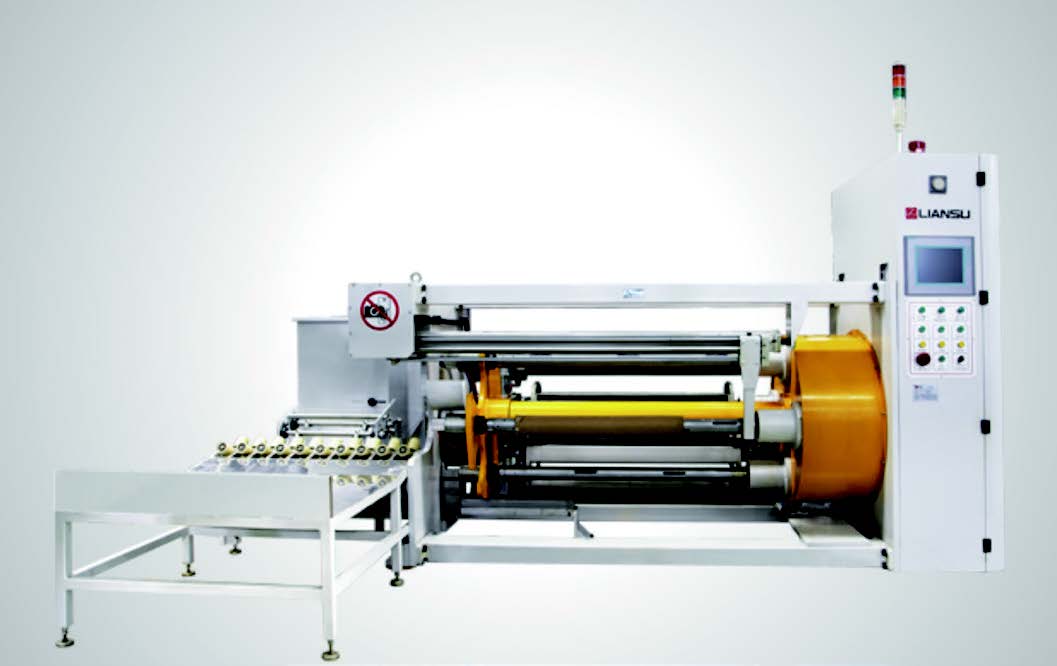

Winding

Full automatic winding machine integrates automatic packing and pipe unloading, with high degree of automation.Sample

-

WINDER

- Smooth winding, good automatic tension control and electronic cam computing method assure the liner motor’ s running constantly and synchronously.

- Even in the high speed of 30 m/min, it can ensure the neat winding.

- Full-auto changing and winding.

- Motor with electronic cam mode assures that arrangement is synchronous with winding. However, it still keeps neat winging in the high speed of 50 m/min.

CUTTER

- Servo resetting and precise cutting length.

DIE HEAD

- The mold adopts cyclone air cooling structure, which can accelerate the cooling speed of the inner wall of the pipe.

EXTRUDER

- Adopting precise imported vertical gearbox, sound off, high-efficiency, with high-efficient stainless steel cooler and metal powder device.

- Optimized screw structure, making the raw material plasticizing and mixed completely.

- Equipped with gravity metering system, real-time testing the production situation.

VACUUM TANK

Moscow, Russia