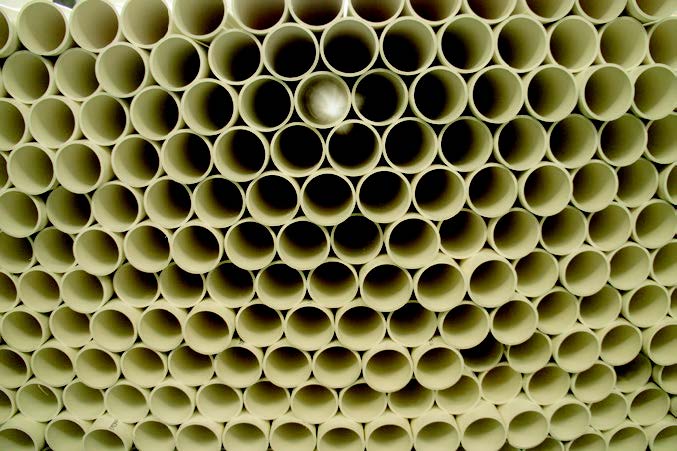

1Industry Demand and Problem

With the growing demand for the centralized feed system in the plastics industry, many automation companies rise at a rapid speed.There are thousands of manufacturers, agents, traders, self-employed businessmen, small workshops, and so on in the country, which claim to be able to manufacture the centralized feeding system.

Many customers do not understand about the situation and find some relatively inexpensive suppliers to support them, butthey have no dedicated engineer, no imported processing equipment, no perfect service team, as well as no strong financial support. In order to save costs, the projects after installation usually have many hidden dangers:

-

Unreasonable fan and pipeline selection, resulting in insufficient output and waste of electricity, to make the powder produced in raw material or wire drawing;

-

Pipeline blockage, is unable to suck the material;

-

The mixed material is layered in the conveying process, and raw material produces static electricity;

-

Poor equipment and installation process, shoddy, short service life, imperfectafter-sales service.

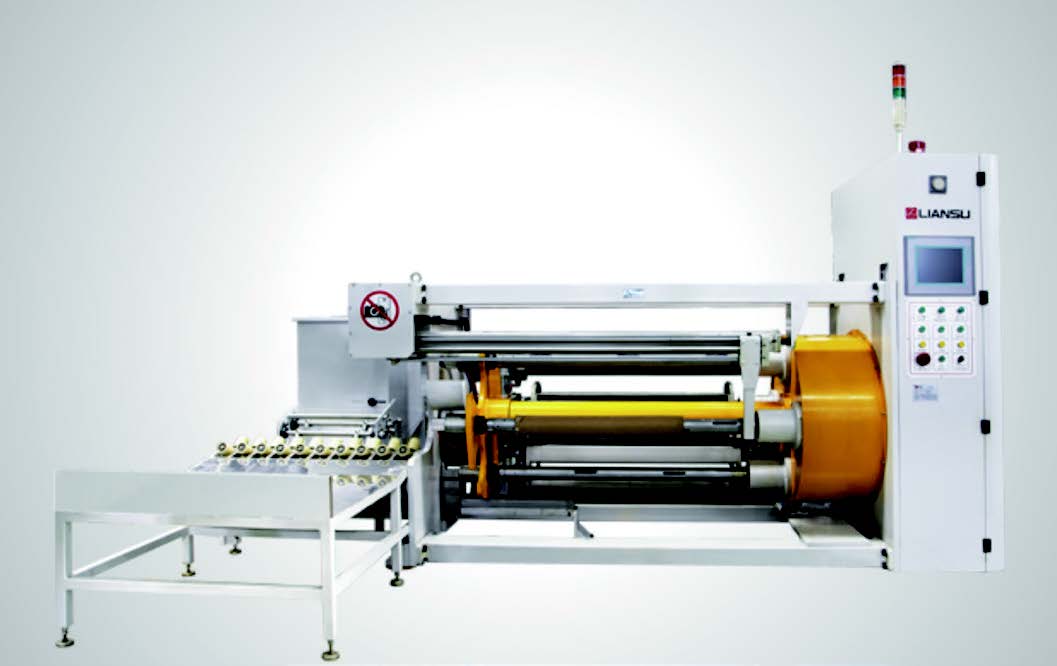

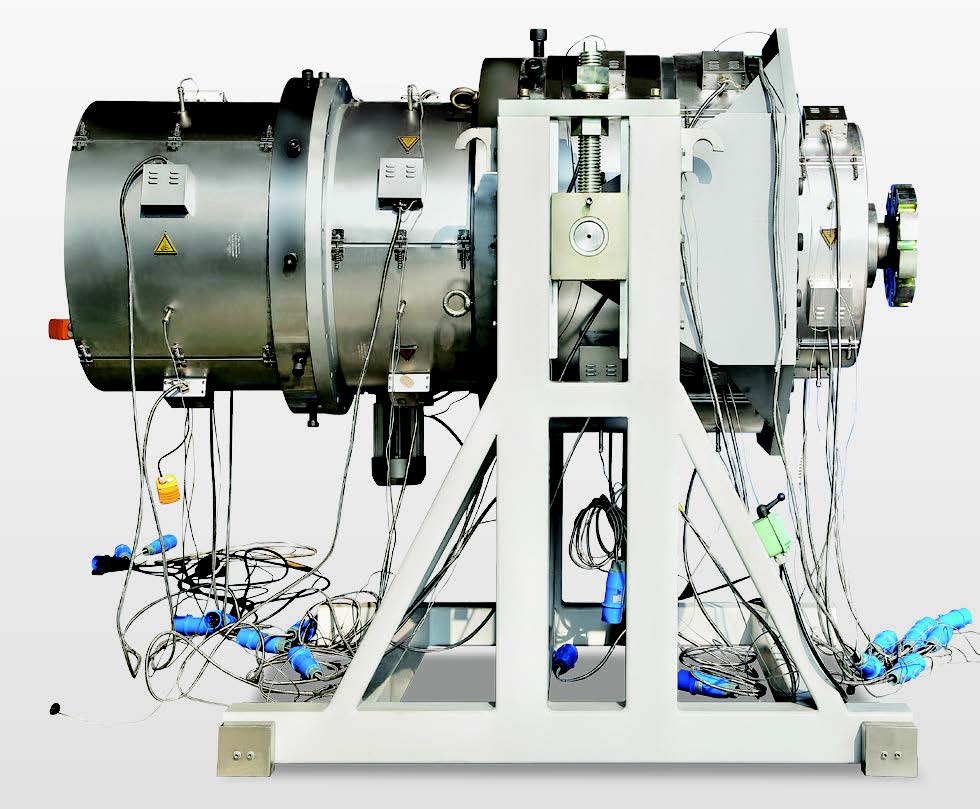

2Liansu Granule Full-automatic Mixing & Converying System

Liansu is committed to designing reasonable scheme for customers

Configure with the high quality product

Professional engineering team, quick service team

Eliminate all worries for you.

Technical Points

-

Safe production, high degree ofautomation:

Using PLC control, good expandability, simple and easy-understanding humanized operation interface, realizing continuous unmanned operation, has multipleprotection function, high safety.

-

Intuitiveand precise management:

Adopt industrial Ethernet remote monitoring, can continuously monitor the margin and consumption of material.

-

Powerfulfunction, strong Flexibility:

According to different ingredients, automatically realize weighing, proportioning, mixing, drying, conveying and other processes.

-

Qualitycontrol, improving efficiency:

Automatic, unmanned, continuous material closed conveyor, ensure no second pollution and waste of material, to improve the production efficiency and stabilize the product quality.

-

Advanced central power system:

Optimize energy consumption, effective energy saving, small covering area, low maintenance frequency.

-

Professional solution design:

Through the combination of material characteristics, air speed, air pressure, engineering structure and other design solutions, effectively solve the problems of producing dust, degradation and static during the process of material being conveyed.

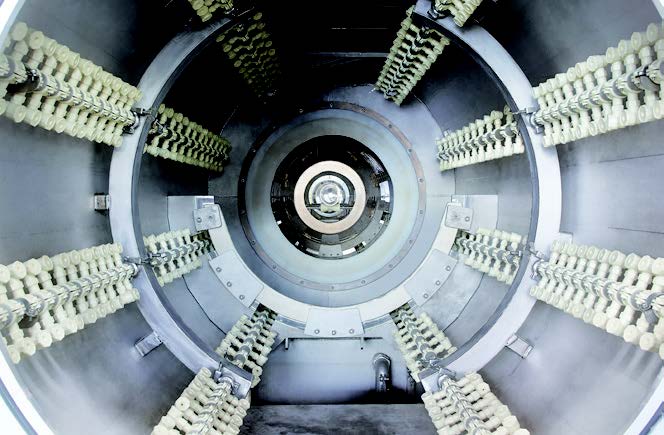

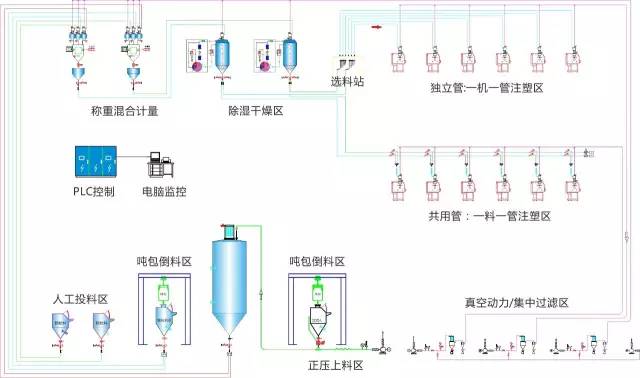

Diagram Ⅰ. Centralized Feeding System Flow Chart