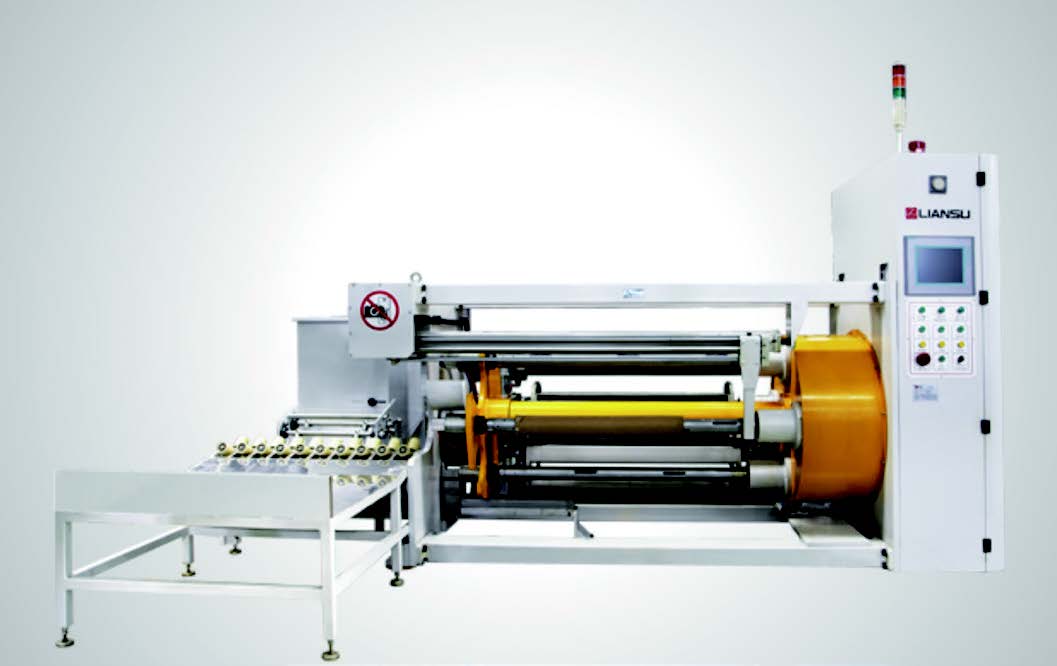

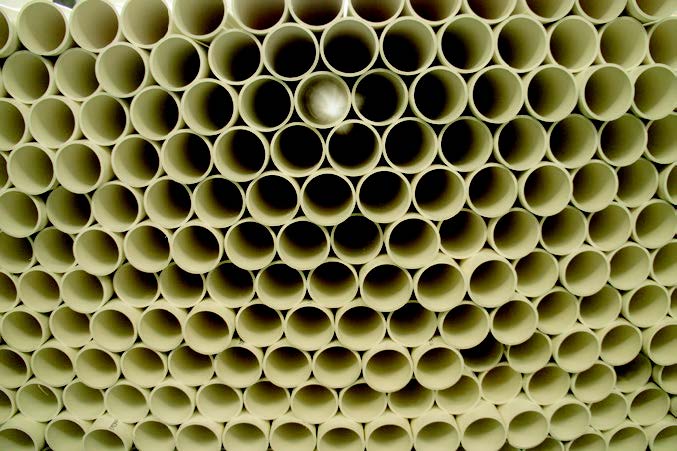

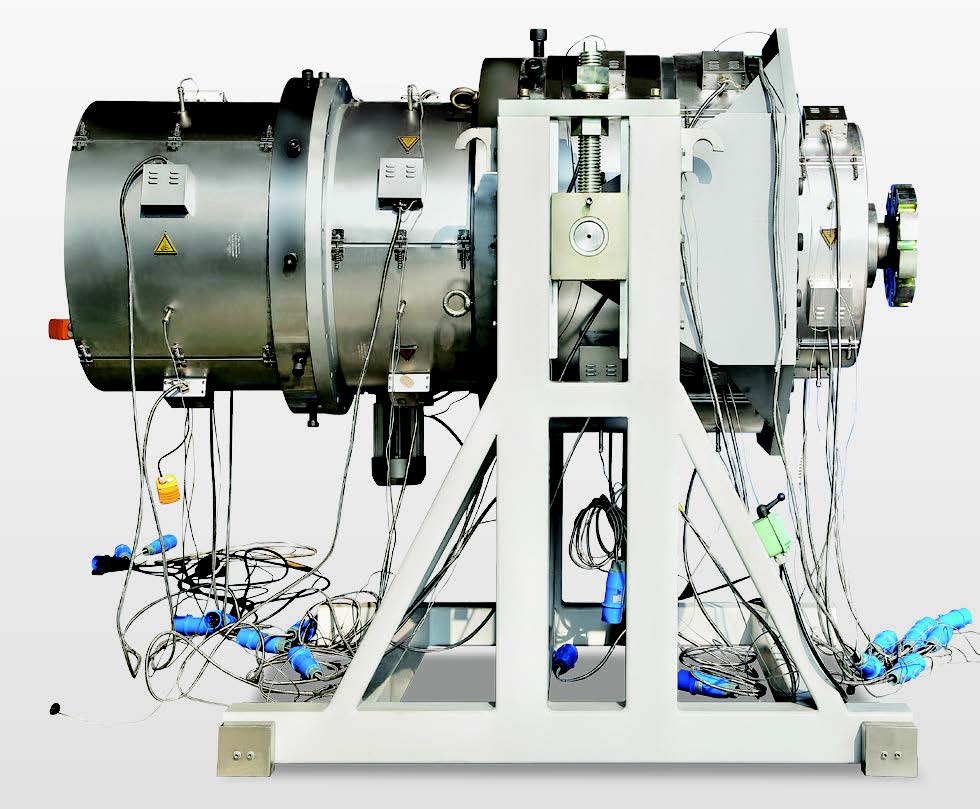

LSZKT24X Trunking Bundling and Bagging Machine

Range of product: 24x14/39x19/30x15 (according to the dimension of packing bag);

Suitable length of product: 1.6~4.0 m (adjustable);

flexibly adapt to single or double trunking extrusion;

Maximum line speed: 18m/min x 2 (double station).

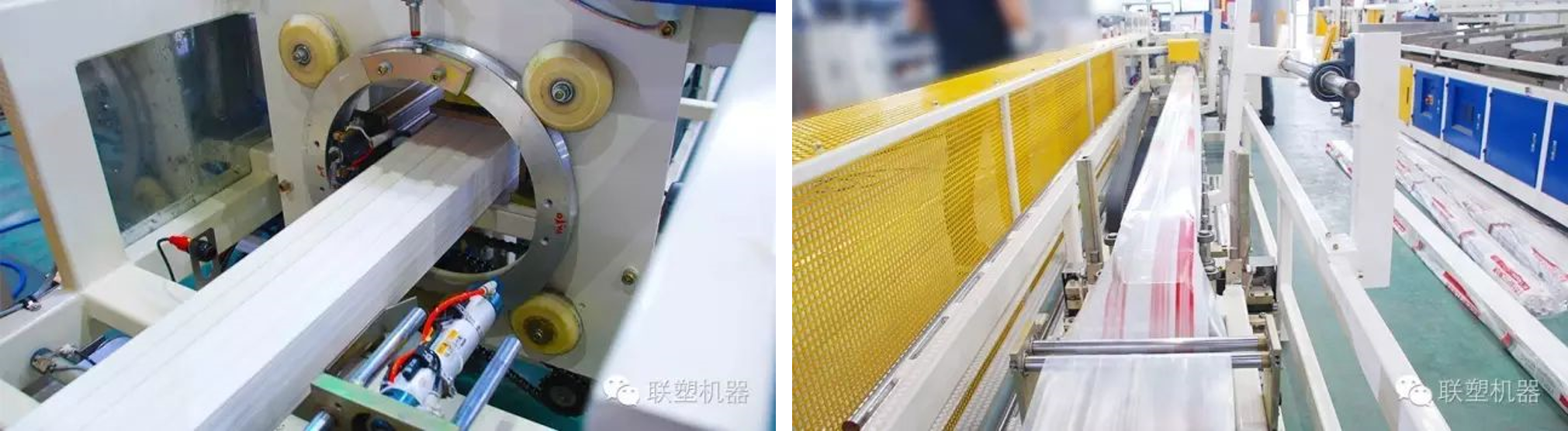

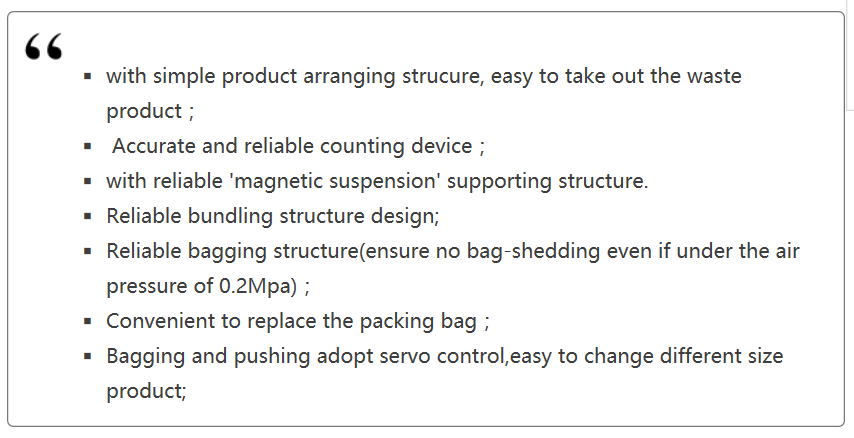

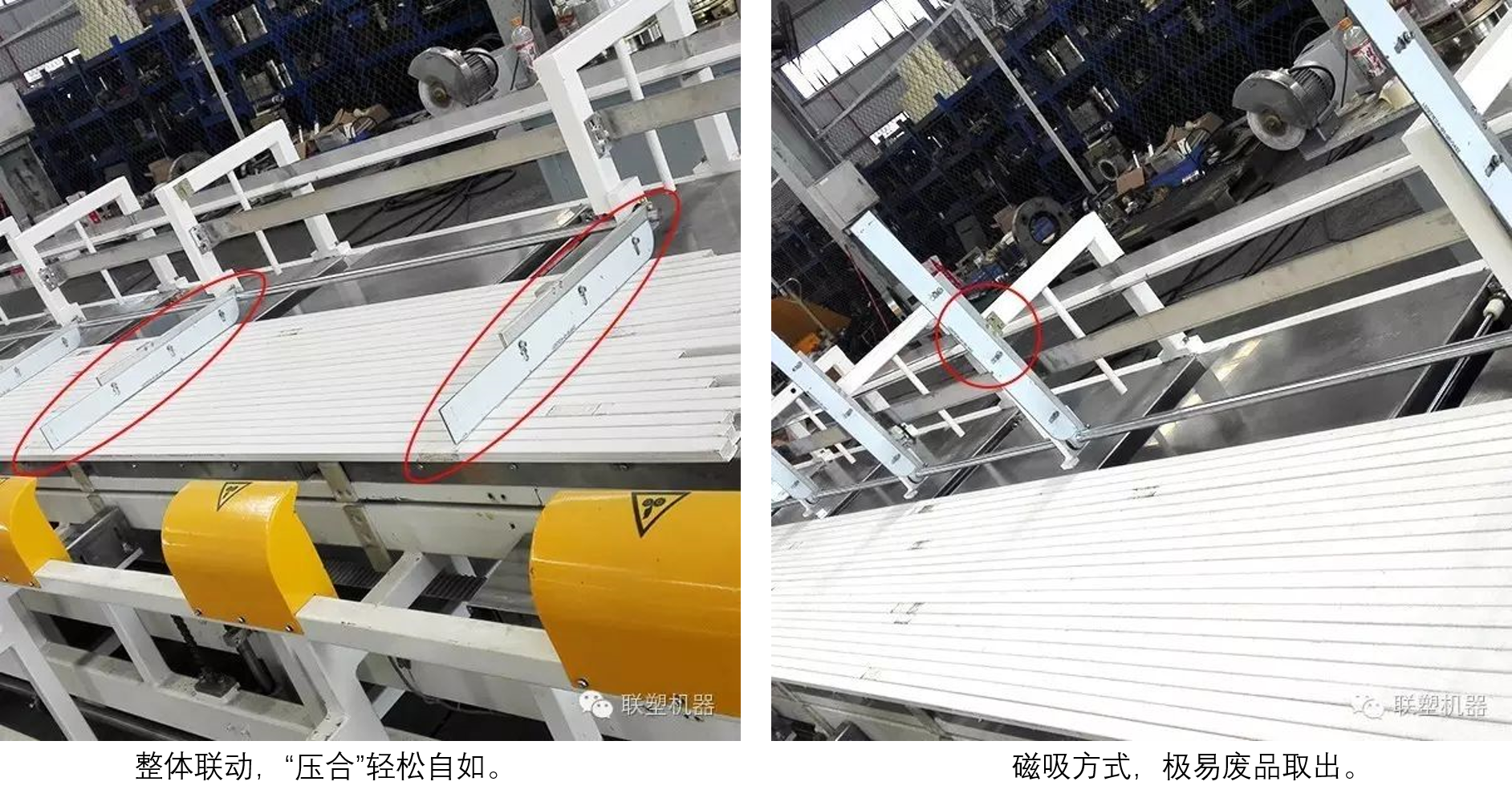

Convenient collecting mechanism

Integral linkage, is simple to fasten.

Magnetic suction structure, very easy to take out the waste product.

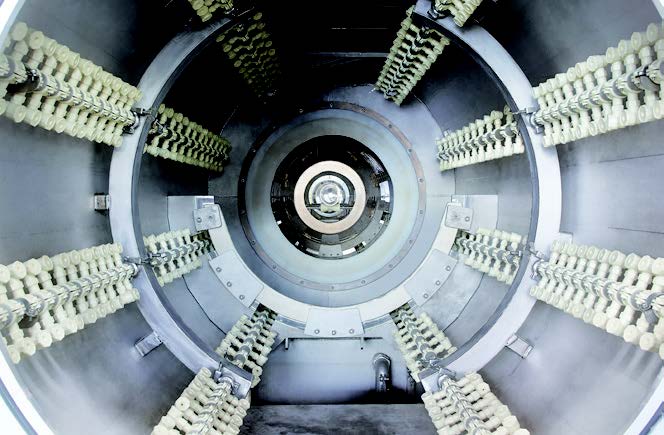

Accurate counting device Magnetic suspension' conveying structure

Optical fiber sensor induction stepping method calculation of layers per bundle.

Mechanical steel ball micro-motion counting,calculate the numbers of trunking in each layer.

Riding wheel adopt 'magnetic suspension' supporting method, no contact, long machanical life, without pneumatic and electric actuator, is simple and reliable.

Reliable strapping mechanism Reliable bagging mechanism

-

Reliable film shortage detecting;

-

Durable hot cutting film structure;

-

Less material consumption of strech film, sufficient strapping force.

-

Reliable bag pulling mechanism, the packing bag will not be disengaging from it even if under the condition of operating 0.2 Mpa low air pressure;

-

Packing bag pulling adopts servo control, accurate and coordinate match of position and speed.

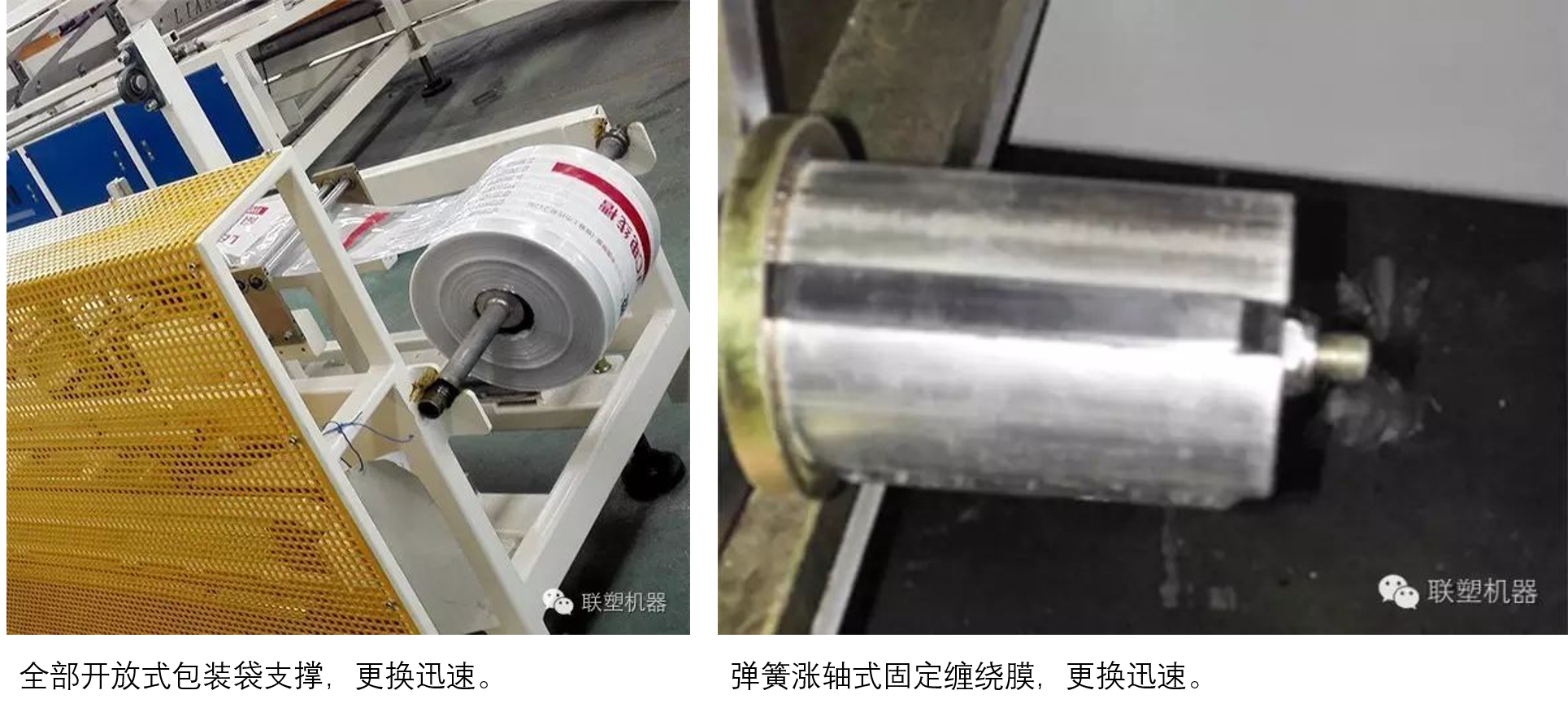

Convenient to replace packing bag&winding film

Open type packing bag supporting structure,can be replaced quickly.

Spring expanding shaft type fixed strech film, can discharge and replace the film quickly.

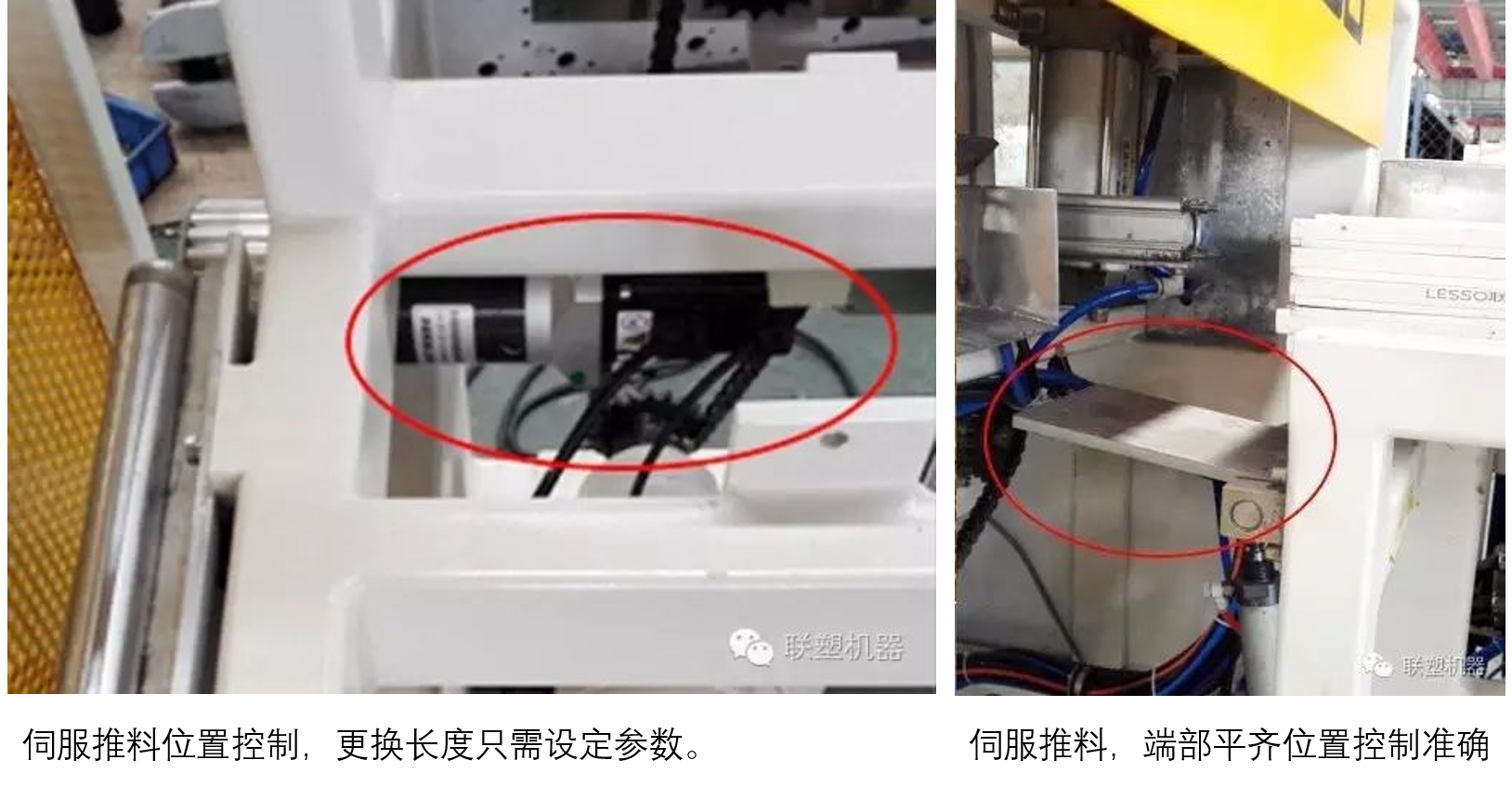

Product conveying adopts servo position control,change length easily and quickly

Conduit conveying by servo position control, only needs to set the parameter while changing product length.

Servo control, product neat arranged and acurate position.

The sealing adopts single air cylinder synchronious rack mechanism

Adopt single air cylinder synchronious driving on the both sides of sealing, stable and durable.

Product Pictures