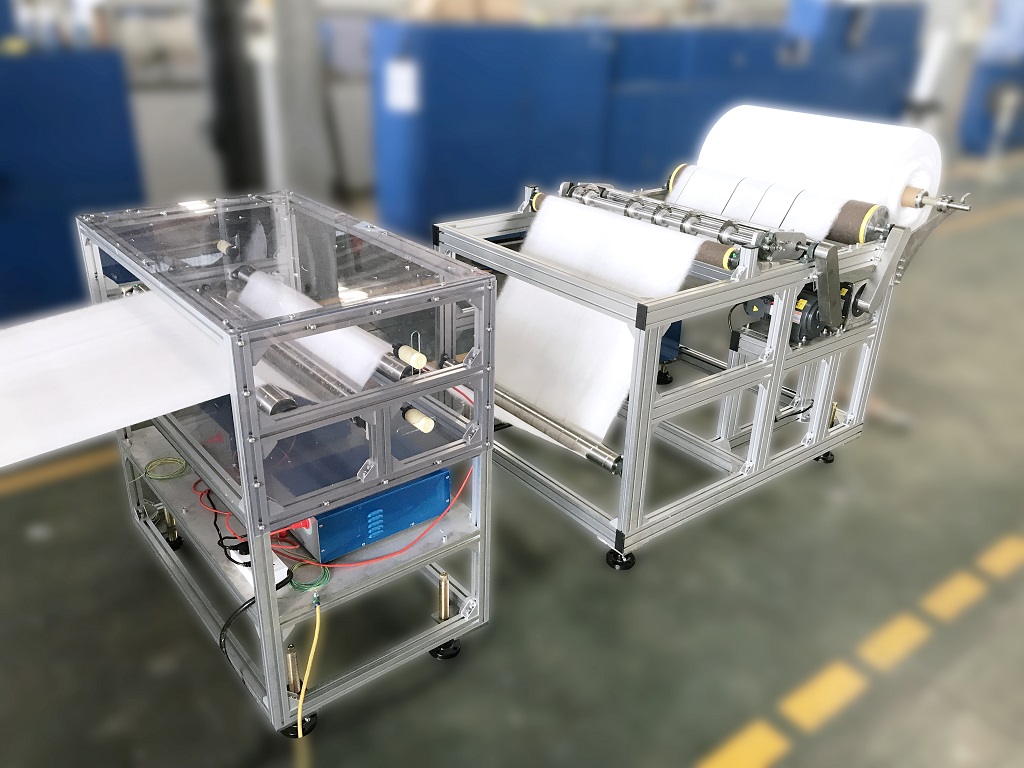

Melt blown fabric extrusion line

Working conditions:

- Temperature: 0℃~40℃;

- Humidity: 85% no condensation;

- Power supply: 3P+N+PE;

- Power voltage, frequency: Vary according to different countries or regions;

- Otput: 90-100 kg/h

- Material: 38CrMoAlA;

- Barrel type: integral type;

- Heating mode: ceramic heating band;

- Heating control zone: 5 zones;

- Heating power: 27,5 kW;

- Cooling system: fan cooling;

- Temperature control range: 50~300℃.

Product advantage

PP melt-blown non-woven production line is stable and reliable, equipped with dual-station non-stop screen changer, melt metering pump, and stable extrusion process.

The mold structure adopts a hanger type flow channel, the melt is evenly distributed, and an automatic coiler can be configured for easy operation.

The produced melt-blown non-woven fabric has a fluffy structure, good anti-wrinkle ability, dust-proof efficiency up to more than 95%.

Product width of 800 - 1600 mm, which is widely used in medical and health materials and other fields.

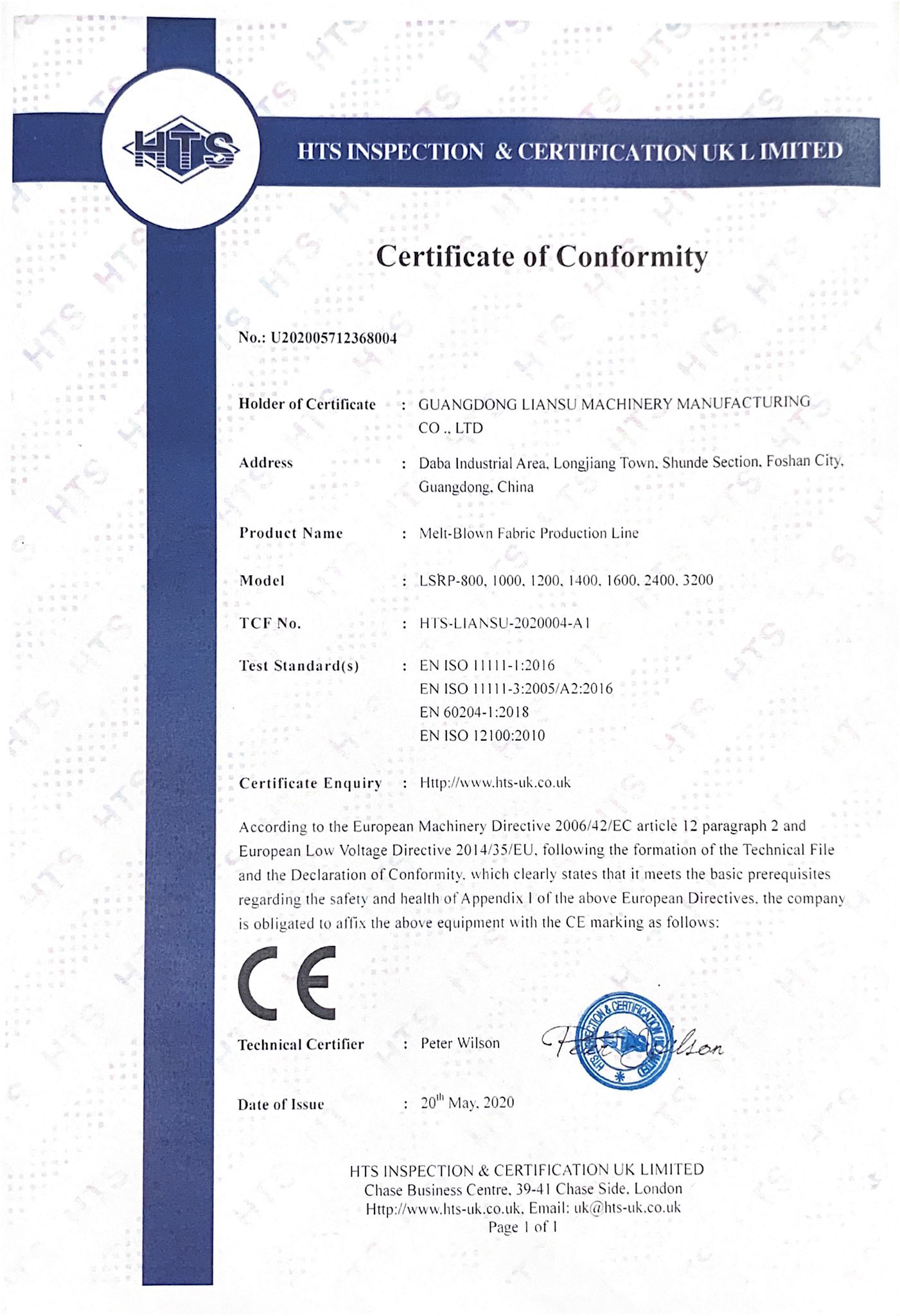

With CE certificate

Technical Specification

|

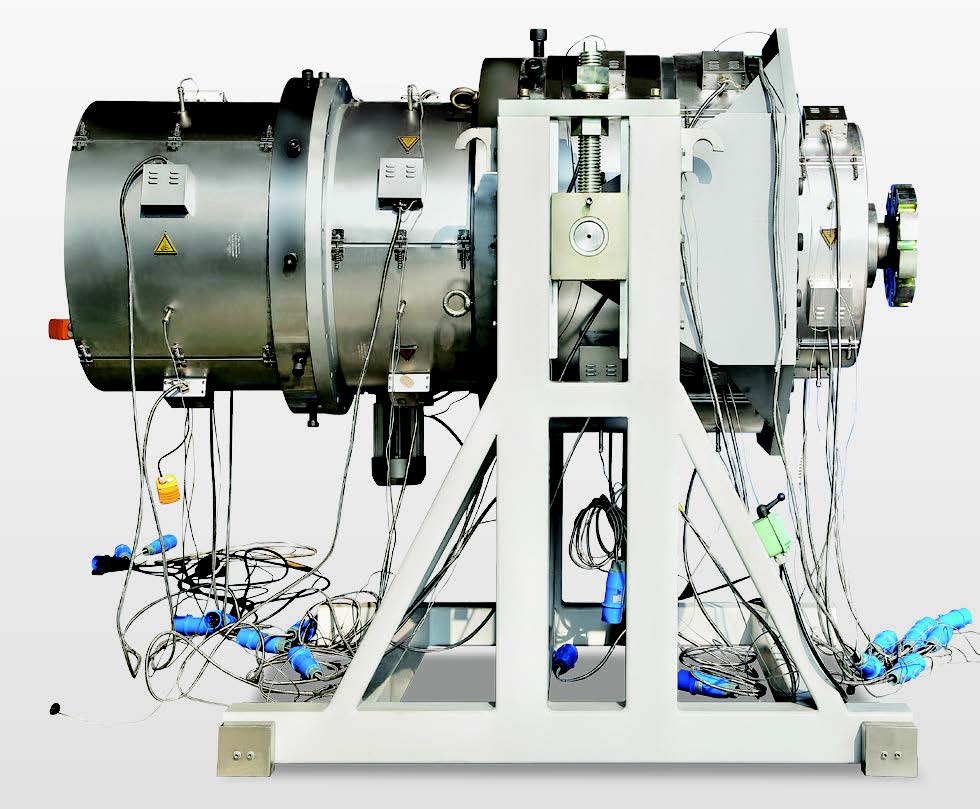

LSS90-30 single screw extruder |

|

|

Type |

LSS90-30 |

|

Output |

90-100 kg/h (PP granule without pressure) |

|

Screw |

|

|

Diameter |

Ø90 mm |

|

L/D ratio |

30:1 |

|

Rotary direction |

rightward |

|

Material |

38CrMoAlA |

|

Inner surface treatment |

Nitriding processing, depth 0.5~0.7 mm |

|

Barrel |

|

|

Barrel type |

Integral type |

|

Inner surface treatment |

Nitriding processing, depth 0.5~0.7 мм, grinding |

|

Heating control zone |

5 zones |

|

Heating mode |

ceramic heating band |

|

Heating power |

27.5 kW |

|

Cooling system |

fan cooling |

|

Cooling power |

5 × 50 W |

|

Temperature control range |

50~300℃ |

|

Main driving motor |

|

|

Main motor power |

55 kW |

|

Motor type |

AC motor (optional) |

|

Connecting method with gear box |

By coupler |

|

Gearbox |

|

|

Auto feeder (with dryer) |

|

|

Feeding way |

vacuum suction |

|

Feeding capacity |

300 kg/h |

|

Drying mode |

automatic control hot air drying |

|

Hopper effective volume |

50 L |

| Main electric control cabinet | |

|

Main components |

Control system: (optional) |

|

Inverter: Inovance |

|

|

low voltage electrics: SIEMENS+ABB |

|

|

solid state relay: CELDUC/Carlo |

|

|

Screen changer |

|

|

Method |

Single plate double stations |

|

Melt pump |

|

|

Driving power |

5.5 kW |

|

Speed regulation with variable frequency |

|

|

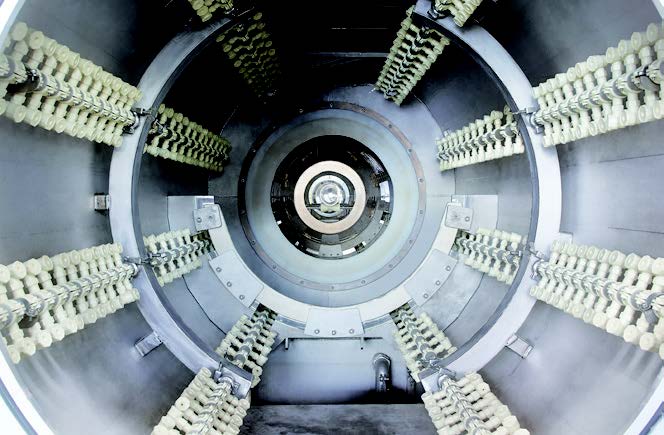

Melt-blown die head |

|

|

Width |

1600 mm |

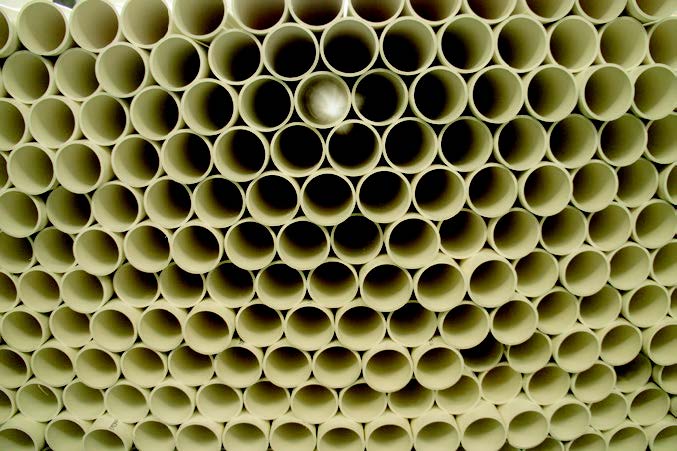

| Equipped with an additional spinneret plate | |

|

Air heating device |

|

|

Pipe heater |

Power 100 kW |

|

Roots fan |

Power 45 kW |

|

Adopt stainless steel braided hose |

|

|

Melt-blown haul-off unit |

|

|

Hauling type |

double belts |

|

Mesh curtain width |

1900 mm |

|

Driving motor |

AC motor |

|

Power |

~2.2 kW |

|

Variable frequency speed regulation |

|

|

Suction fan power |

3.7 kW |

|

Equipped with an additional mesh curtain |

|

|

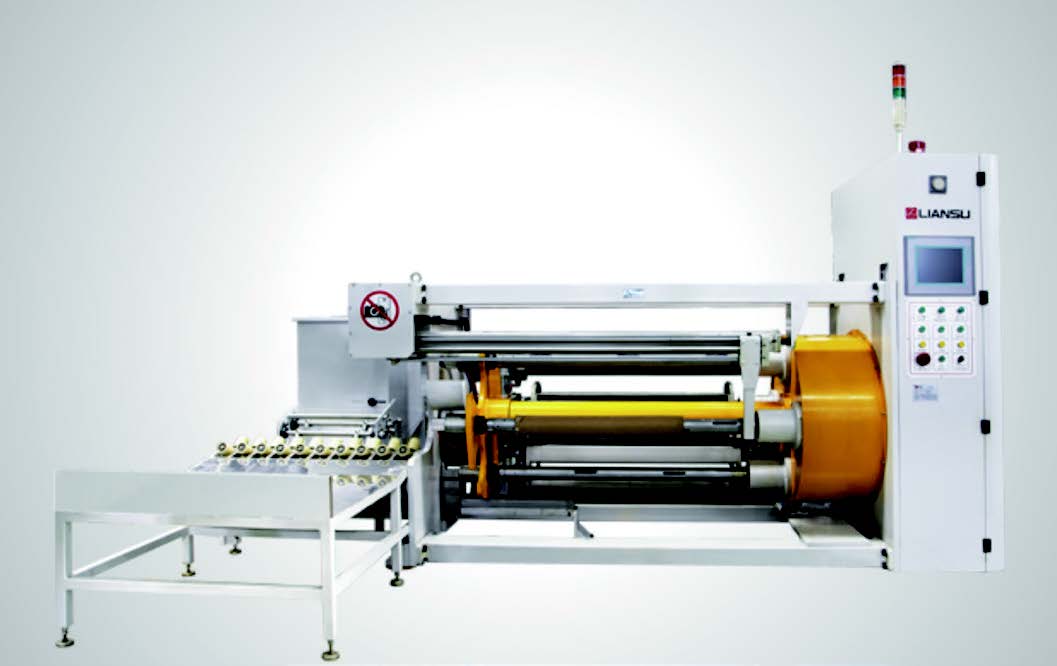

Melt-blown winding machine |

|

|

Torque motor control |

|

|

Edge cutting knife |

4 pcs. |

|

Winding station |

1 |

|

Air shaft spec. |

Ø76×1600 |

|

Air shaft quantity |

2 |

|

Static electret device |

|

|

Output voltage adjustable range |

0-120 kV |