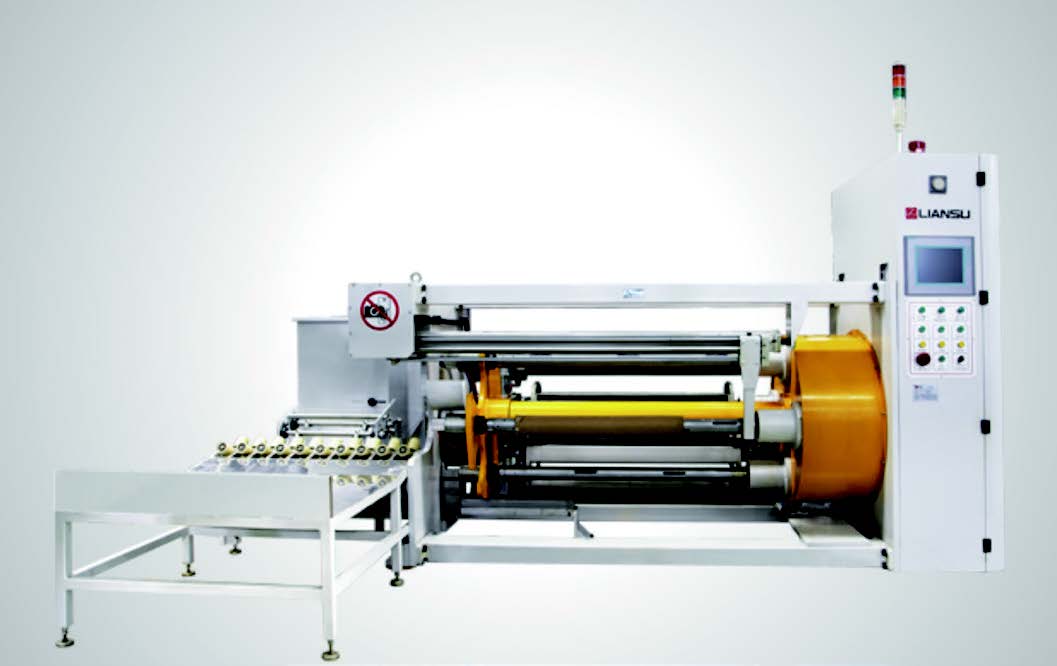

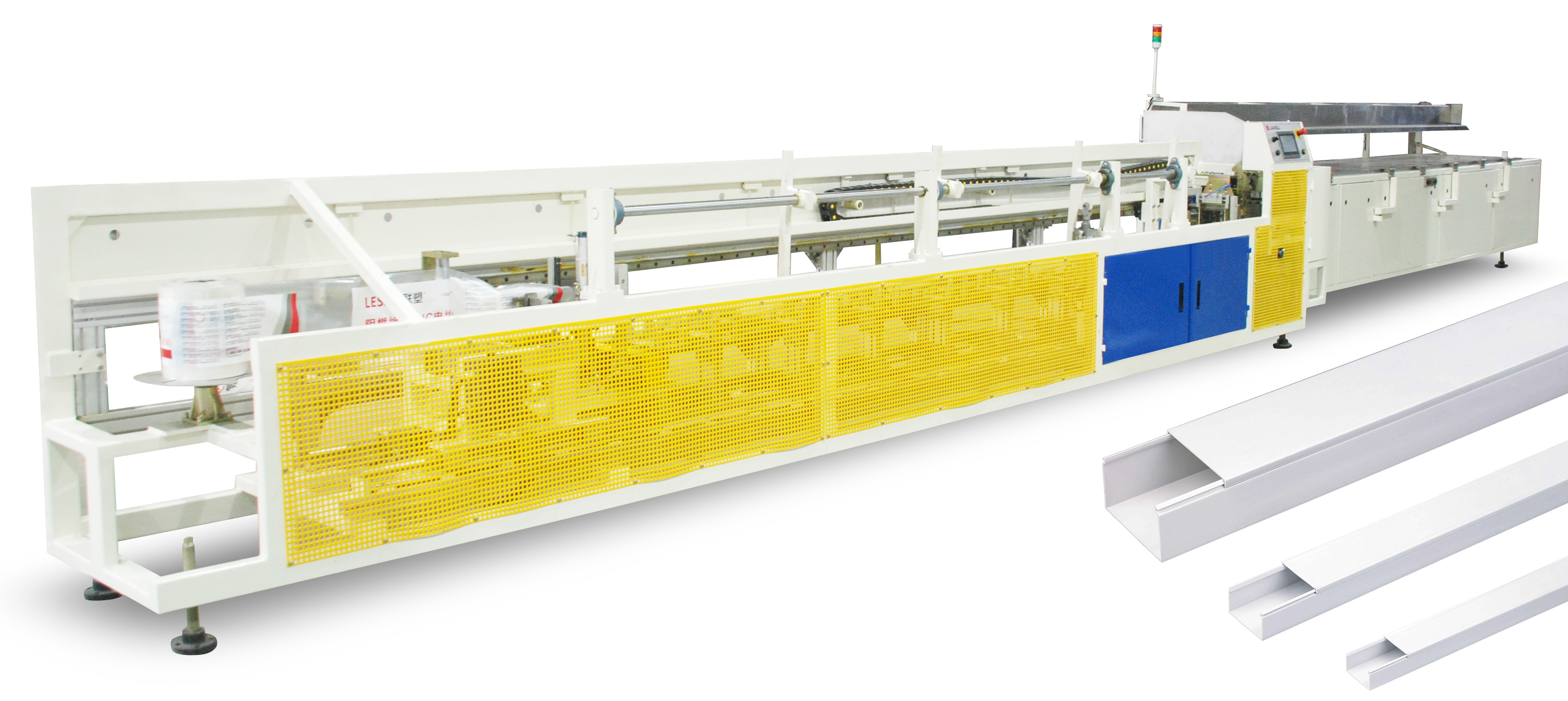

Automatic Bundling & Bagging machine for PVC Trunking

- For packing 3.8 meter trunking, the packing and bagging cycle of each bundle is less than 1 minutes. The two adjacent lines can be designed and packed in the form of “face-to-face”, which is convenient for one person to operate two machines at the same time.

Specification

Product range: 24x14/39x19/30x15

Available product length: 1.6~4.0m (continuous and adjustable)

Can flexibly adapt to single/dual trunking extrusion

Trunking length 3.8m, the packing cycle of each bundle of product is 59.2s.

02

Features

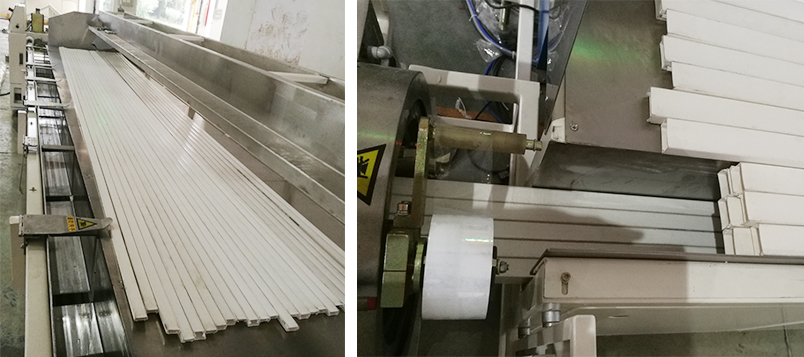

The material arrangement mechanism is divided into up and down layer, and the packaging efficiency is high.

The machine occupies a small area and saves installation field.

Reliable "magnetic suspension" material support mode;

The clamping mechanism is reliable.

Reliable bagging structure (even at low pressure of 0.2 Mpa can ensure that the bag does not take off, can adapt to the larger deviation of the bag);

The ends leveling with buffering and good leveling effect.

Bagging, material arrangement and pushing are all controlled by servo system. It is easy to change specifications. It only needs to set the specification of trunking on the operation panel.

Convenient and efficient "material arrangement" mechanism

Large storage space

Up layer preparation

Down layer synchronous packing

Save installation field

The width of the tail frame of the packing bag is 650 mm, which is convenient for placing the material cage.

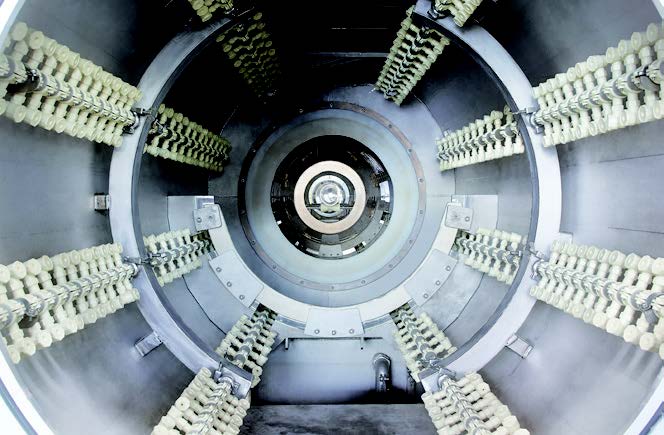

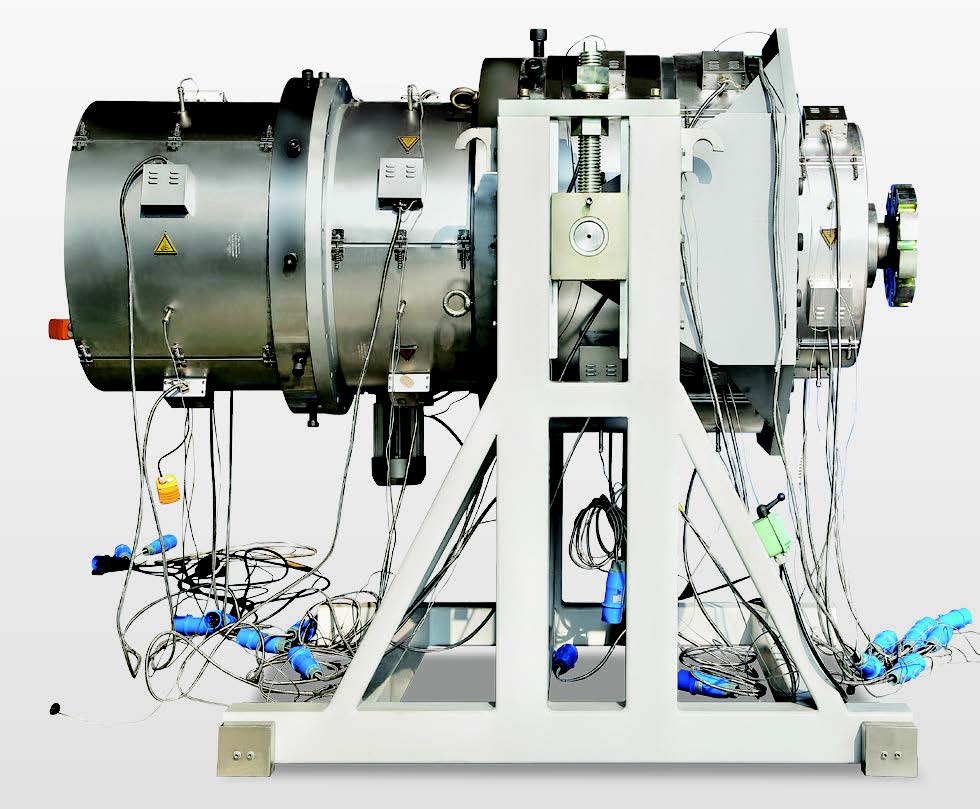

Reliable "magnetic suspension" material support mode

All the supporting wheels are supported by magnetic suspension. No contact, long mechanical life, no pneumatic and electric actuators, simple and reliable.

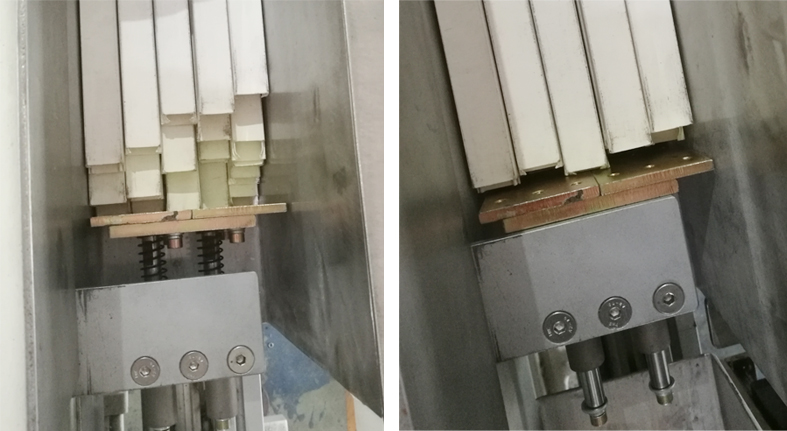

Trunking end leveling mechanism with buffering

The end leveling is equipped with 50mm spring buffering which has good leveling effect.

All drive are driven by servomotor + planetary reducer. Simple for changing the spec

Servo motor and planetary reducer are used in the four mechanical structures of material arranging, pushing, winding and bagging. When replacing the specification, you just need to set the specification parameters of the trunking on the touch screen, and all the position parameters are automatically calculated by the program.

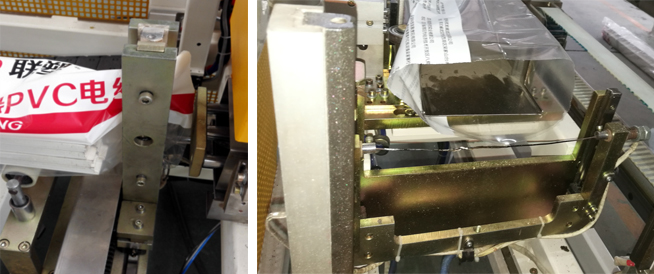

The sealing adopts single cylinder synchronous rack mechanism

The sealing adopts single cylinder, synchronization between left and right gear rack, both sides are equipped with heating,good sealing effect.

High packaging efficiency

For packing 3.8 meter trunking, the packing and bagging cycle of each bundle is less than 1 minutes.

The two adjacent lines can be designed and packed in the form of "face-to-face", which is convenient for one person to operate two machines at the same time.

Sealing Effect