Ⅰ. Summary

- Pipe diameter range: Ø16 — Ø32mm

- Hauling speed Line speed: 1-25 m/min (20 mm single pipe gurantee line speed 20 m/min)

- Center distance of two stations: 260 mm

- Maximum output: 550 kg/h

- Total length of production line: 50000×5000×3500 mm

II. Equipment Composition

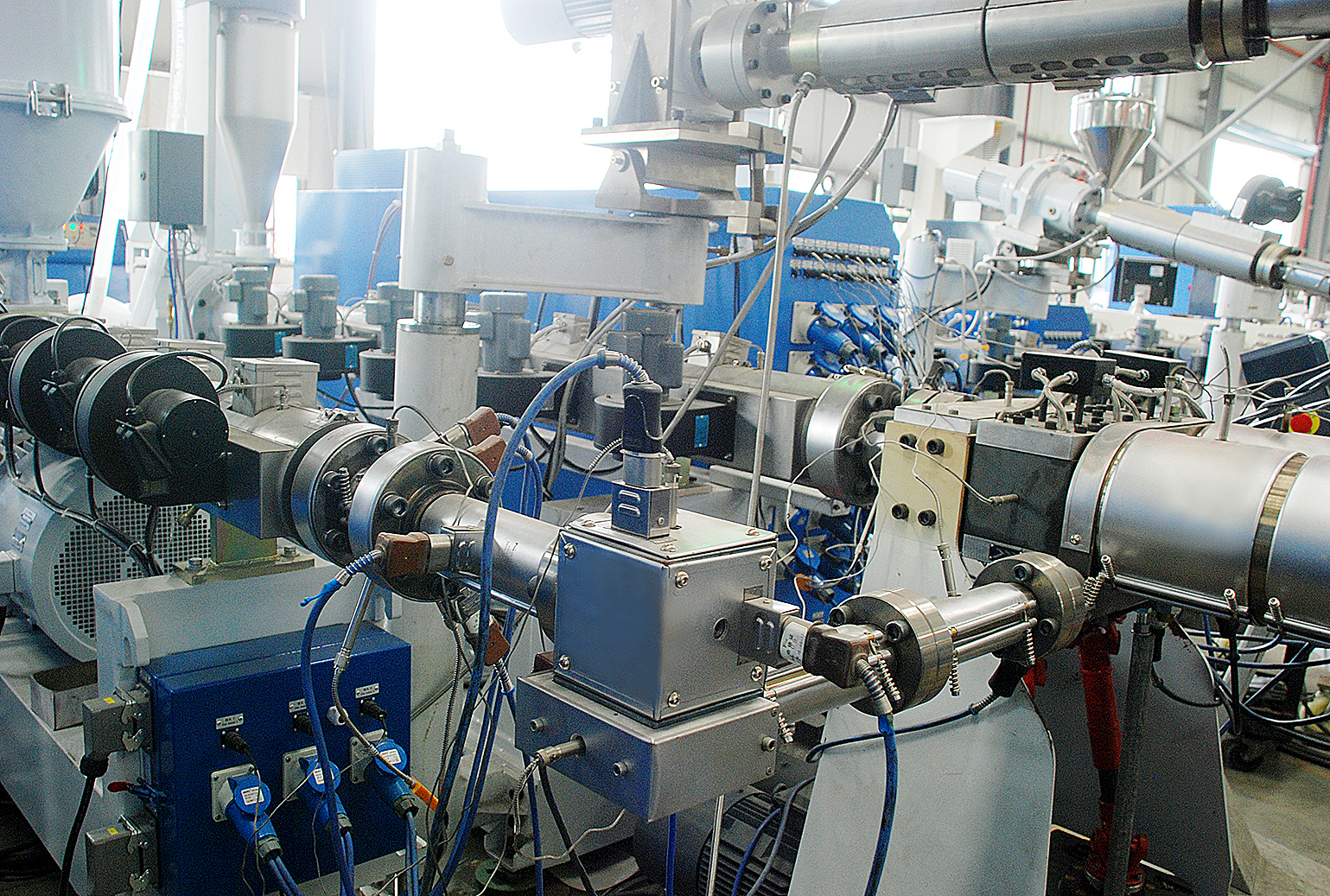

LSS65-40 Single screw extruder

LSS50-40 Single screw extruder

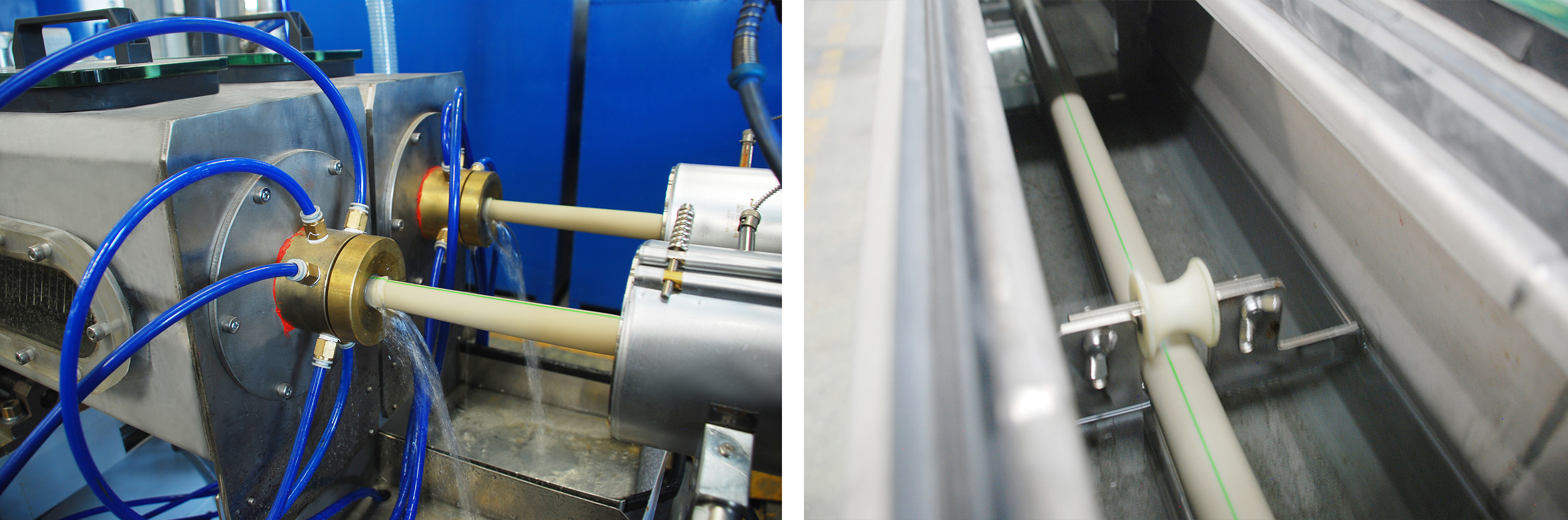

LSDPZ-32PPR Double pipe and double body vacuum tank

LSDPL-32 PPR Dual-pipe immersion cooling tank

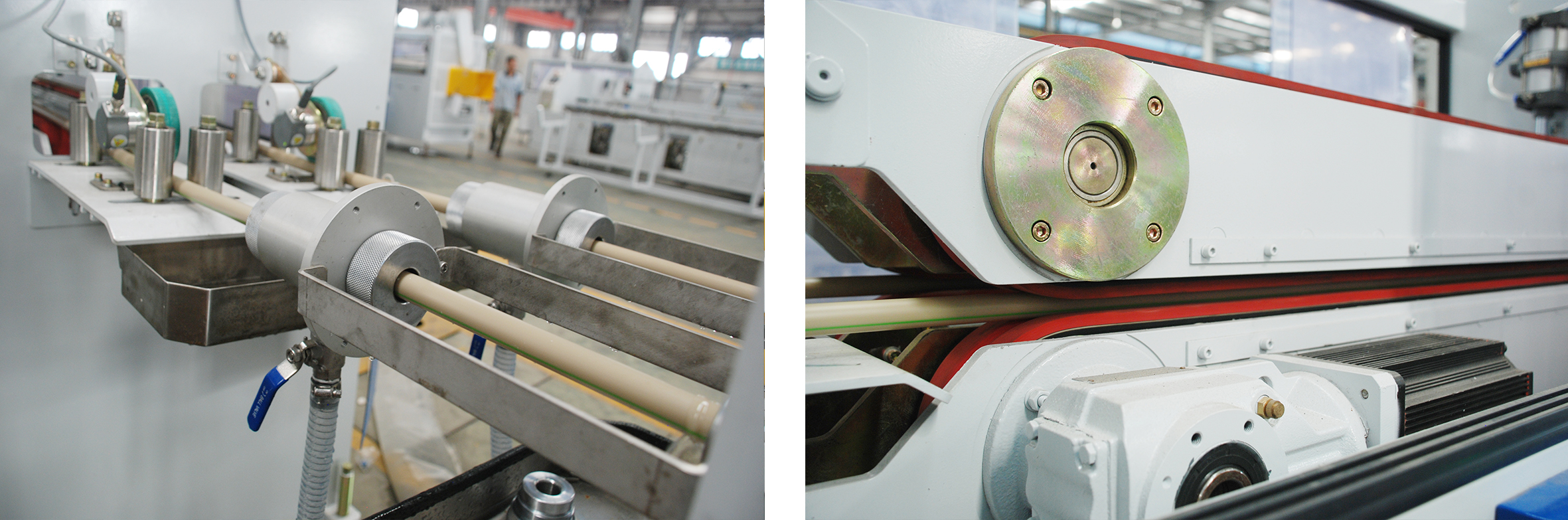

LSDPQ2-32 Double-pipe hauling and flying knife cutting combination machine

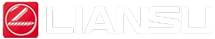

LSZKT-32P(6) On-line automatic bundling and bagging sewing and packaging machine for pipes

LSS-30-25 Color strip coextruder

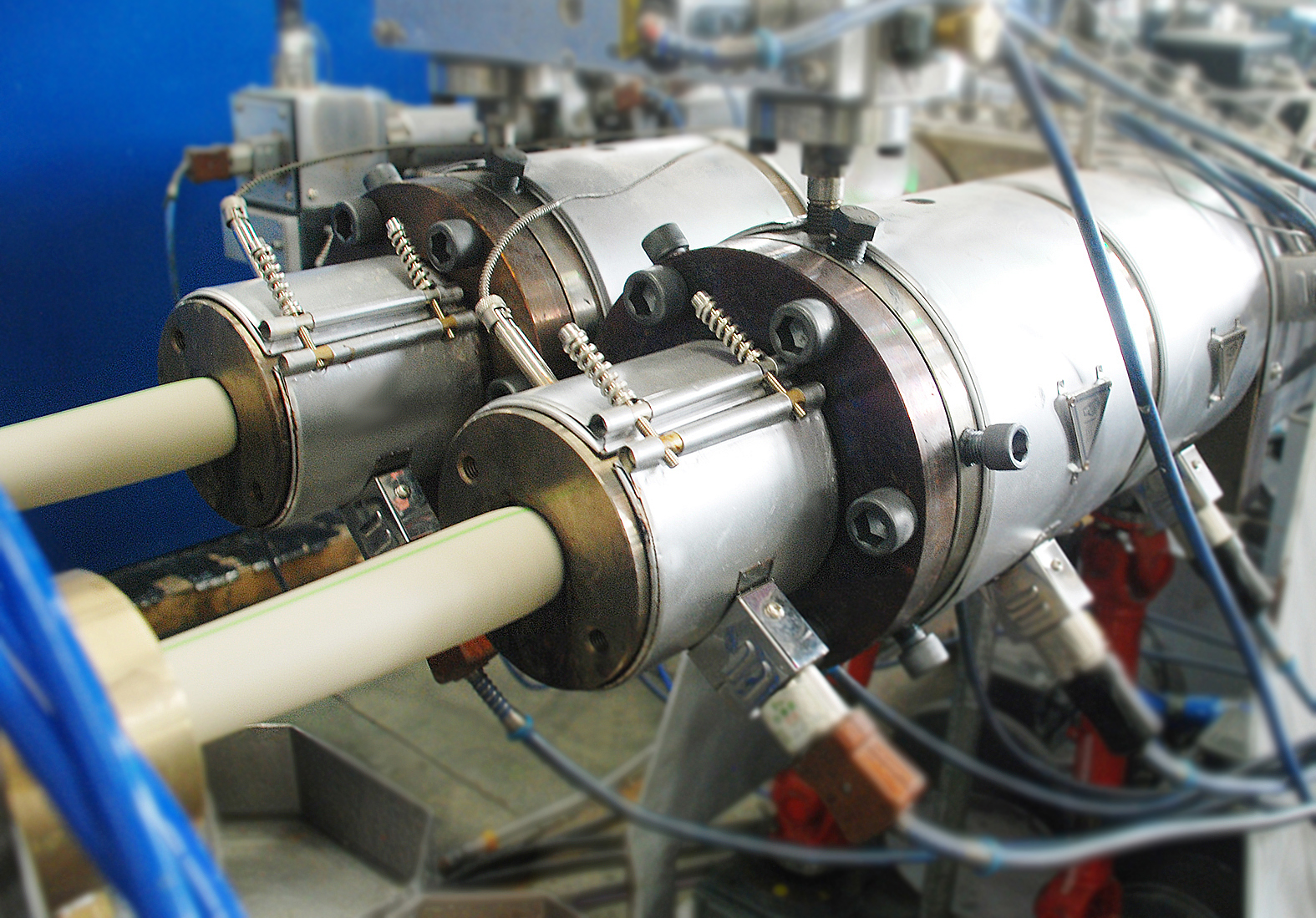

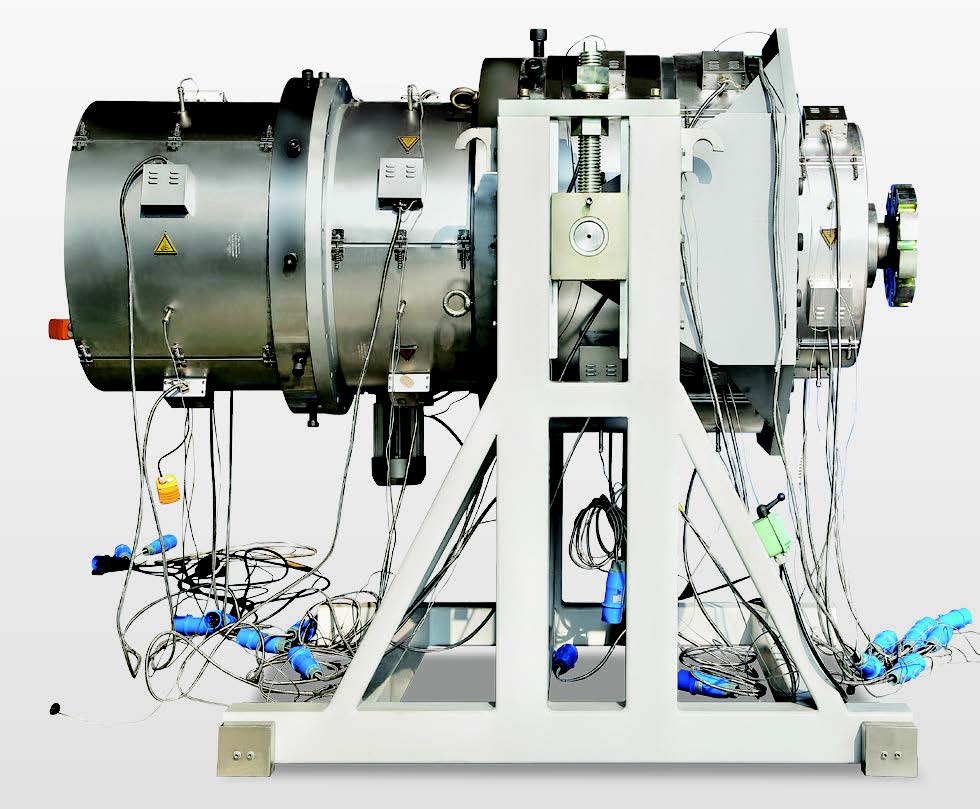

LSDPM-32PPR Extrusion Die for Dual Pipe

III. Technical Characteristics

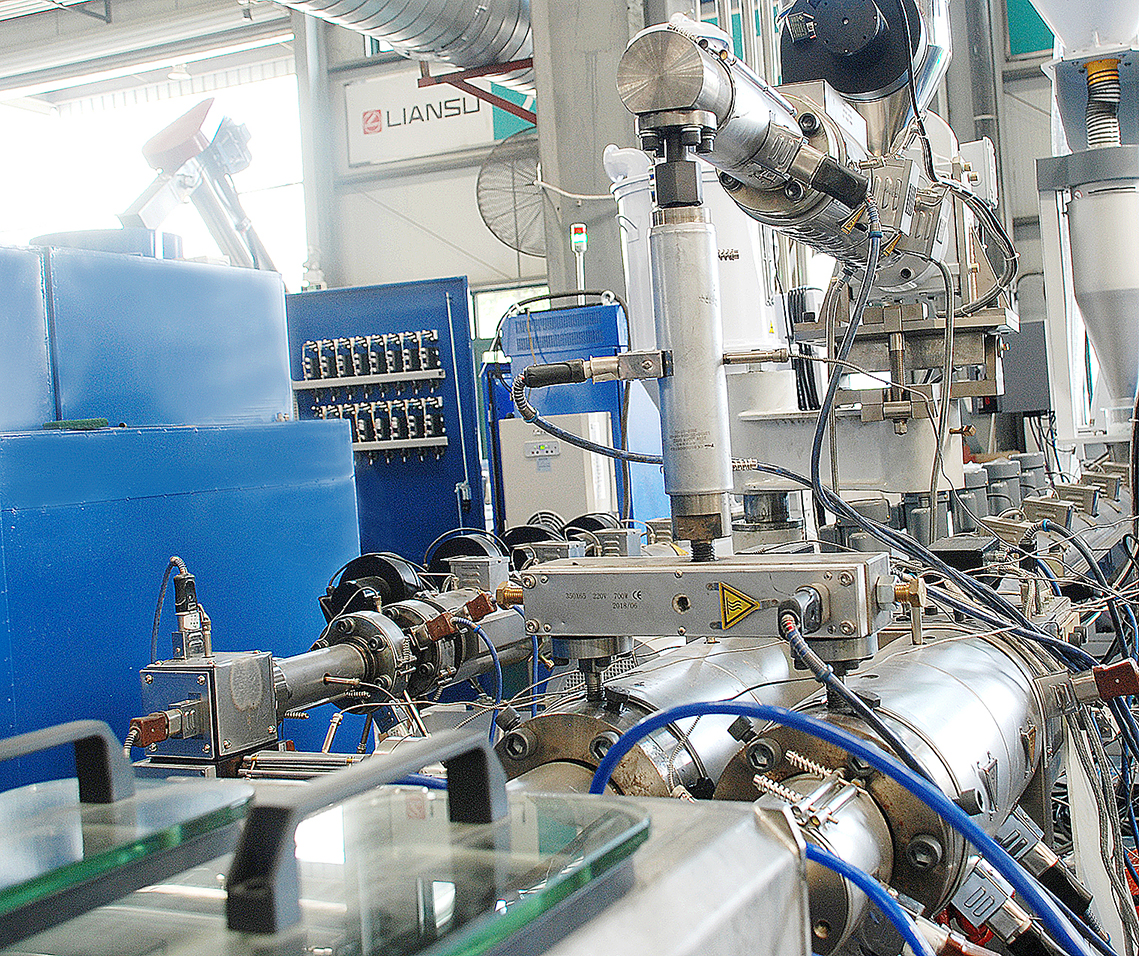

40 D Single Screw Extruder(outer/inner layer)

- PPR special screw with large L/D ratio, ensures high yield and good plasticizing effect.

- Permanent magnet synchronous servo motor for extruder is equipped to ensure high efficiency, low consumption and low noise in high-speed production.

- Unique control system guarantees stable extrusion volume of inner and outer layers and independent workstations.

- Equip with colour master batch lost-in-weight and integration with main machine control system.

- Configuration of process data acquisition system for single-machine edition to improve production efficiency and quality management

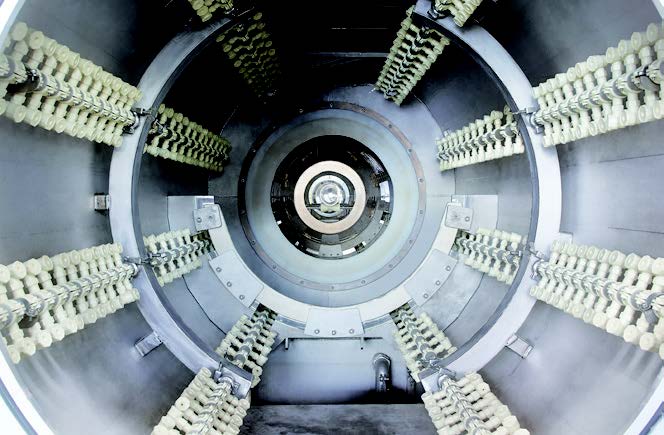

Double pipe double tank body vacuum tank

- Vacuum frequency conversion control, energy saving and low noise

- Equipped with vacuum abnormal alarm, automatically remove waste pipes

Double pipe hauling flying knife cutting combination machine

- Equipped with servo motor for haul-off unit to ensure the full range stable speed.

- Equipped with servo mechanism for cutting machine to ensure accurate cutting positioning.

On-line automatic bundling, bagging and sewing packing machine for pipes

- Pipe diameter range: ∅16~∅32 mm

- Pipe length:2.6~4.0 m (Adjustable gear)

- Maximum line speed: 25 m/min (Double pipe double station)

- Less space, simple and stable structure, superior user operation experience.

- Configuration of pre-packaging weighing device to ensure the pass rate before packaging.

- Configuration of real-time data acquisition.

Double pipe double layer extrusion die