Volokolamskoye shosse 89 bld 1,

Moscow, Russia

-

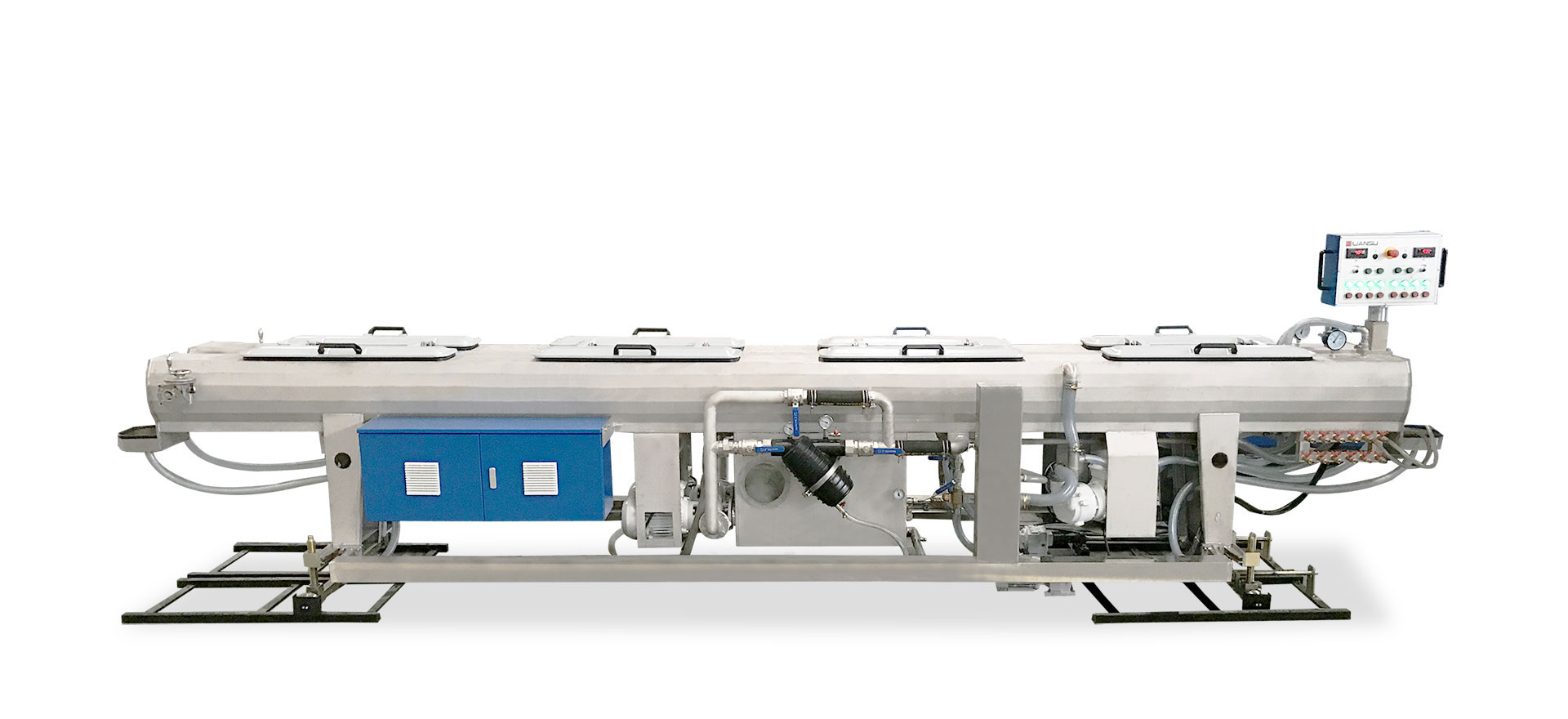

- Intensive cooling of the pipe with the help of numbers of spray nozzles.

- Axial adjustment of tank on slide rails with locking arrangement.

- Self cleaning type spray nozzles with wide opening for intensive cooling of the pipe.

- Aerclyic transparent cover for easy inspection.

-

- Model

- Pipe Range, mm

- Hauling Speed, m/min

- Installed Power, kW

- Output, kg/h

- Line Length, m

- LSP-63CPVC

- Ø16-Ø63

- 0.8-12

- 37

- 180

- 28

* Test and accept based on Liansu standard formula

-

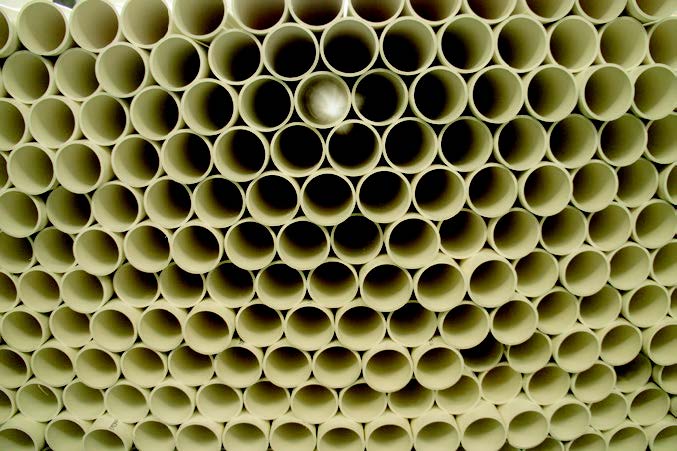

CPVC Pipe Production Line

Ø16-Ø63 mm

PIPE RANGE

0.8-12 m/min

MAX HAULING SPEED

37 kW

TOTAL INSTALLED POWER

180 kg/h

MAX OUTPUT

CPVC Pipe Production Line

Ø16-Ø63

PIPE RANGE

12 m/min

MAX HAULING SPEED

37 kW

TOTAL INSTALLED POWER

180 kg/h

MAX OUTPUT

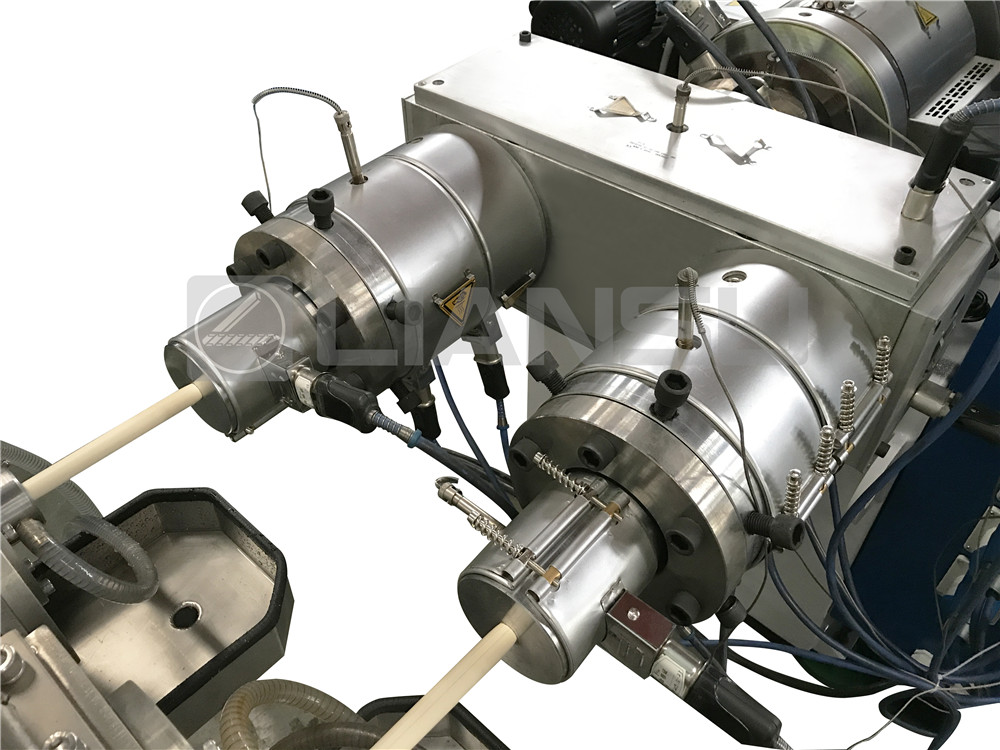

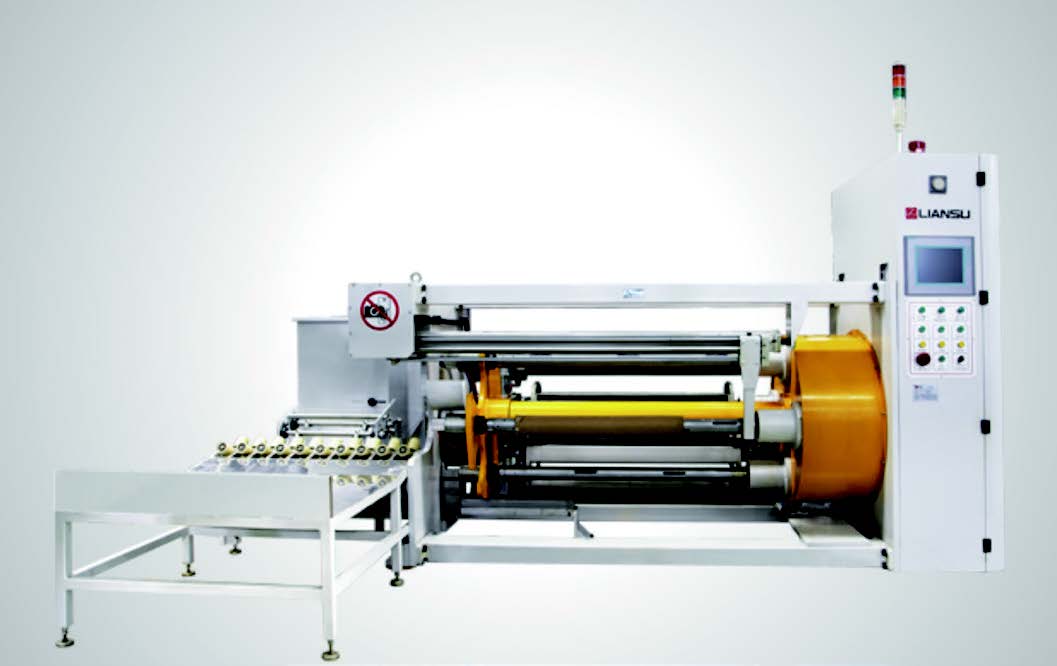

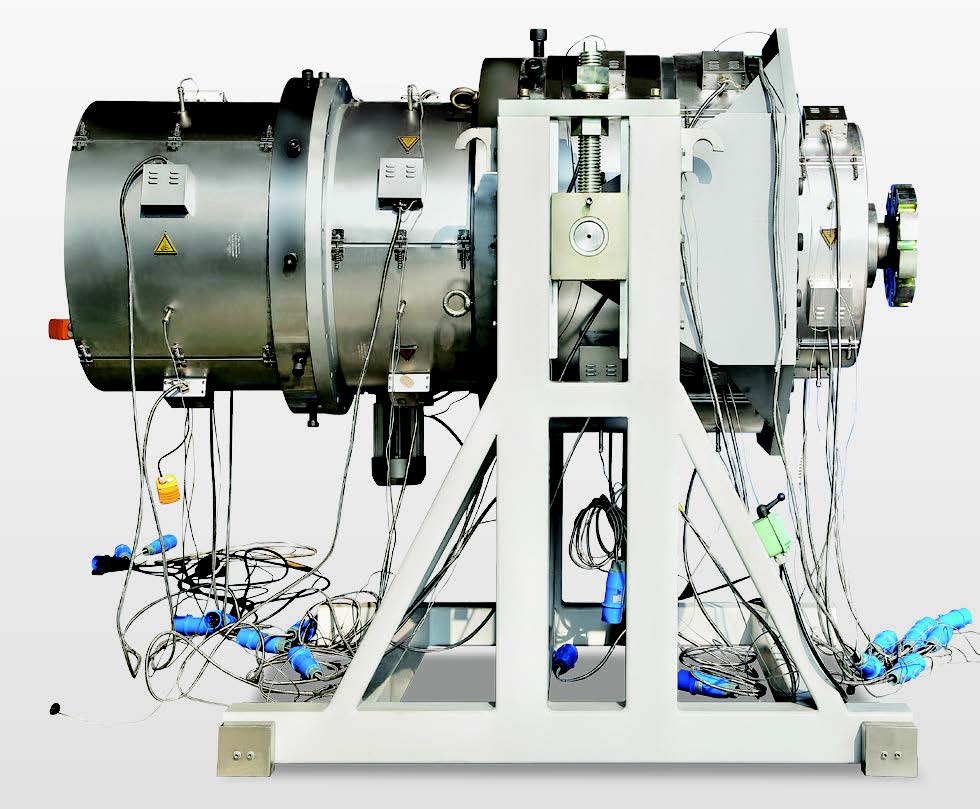

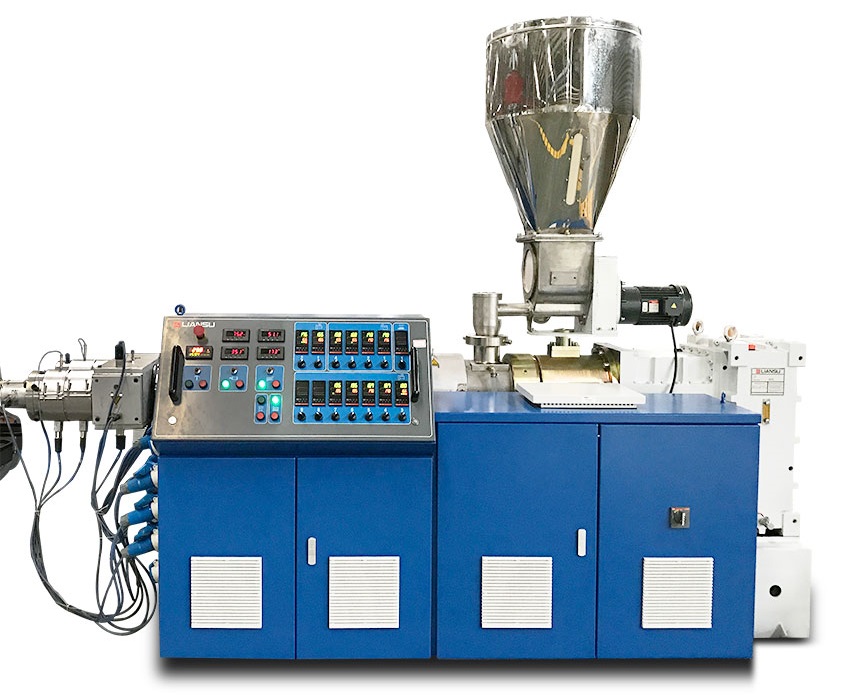

Extruder

Optimized screw designed for CPVC compound material, with accuracy temperature control system, Compared with the conventional AC asynchronous motor, the permanent magnet synchronous servo motor for extruder can reduce 1 ~ 2 power levels, reduce noise and save energy.

Extruder

Optimized screw designed for CPVC compound material, with accuracy temperature control system, Compared with the conventional AC asynchronous motor, the permanent magnet synchronous servo motor for extruder can reduce 1 ~ 2 power levels, reduce noise and save energy.Mould Design

Reasonable flow channel design ensures large extrusion capacity and compression ratio of the die, and the die structure is convenient for quick installation and disassembly.Vacuum Tank

The double-body vacuum tank is controlled independently. The vacuum adopts negative pressure closed-loop to automatically adjust the vacuum degree. The quality of pipe production is improved. The noise is reduced by more than 30 dB, and the energy saving is 30 ~ 85%.

Vacuum Tank

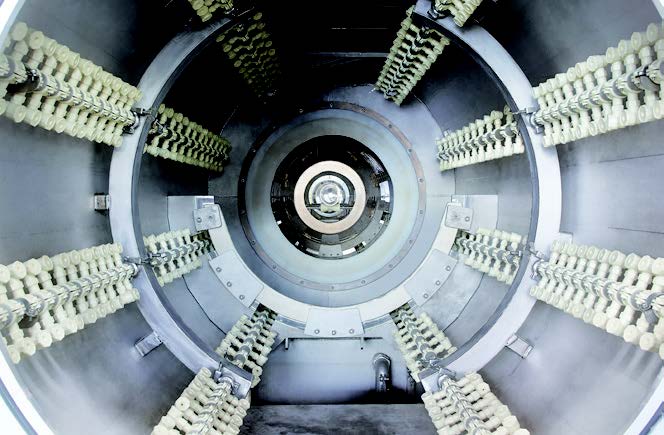

The double-body vacuum tank is controlled independently. The vacuum adopts negative pressure closed-loop to automatically adjust the vacuum degree. The quality of pipe production is improved. The noise is reduced by more than 30 dB, and the energy saving is 30 ~ 85%.Haul-off Unit

Each hauling station is controlled independently, and independent permanent magnet synchronous servo motor scheme is adopted to ensure large speed regulation range. It can meet the requirements of fast hauling of small-sized pipe and slow hauling of large-size thick wall pipe at the same time, with stable speed and strict synchronization of each caterpillar.

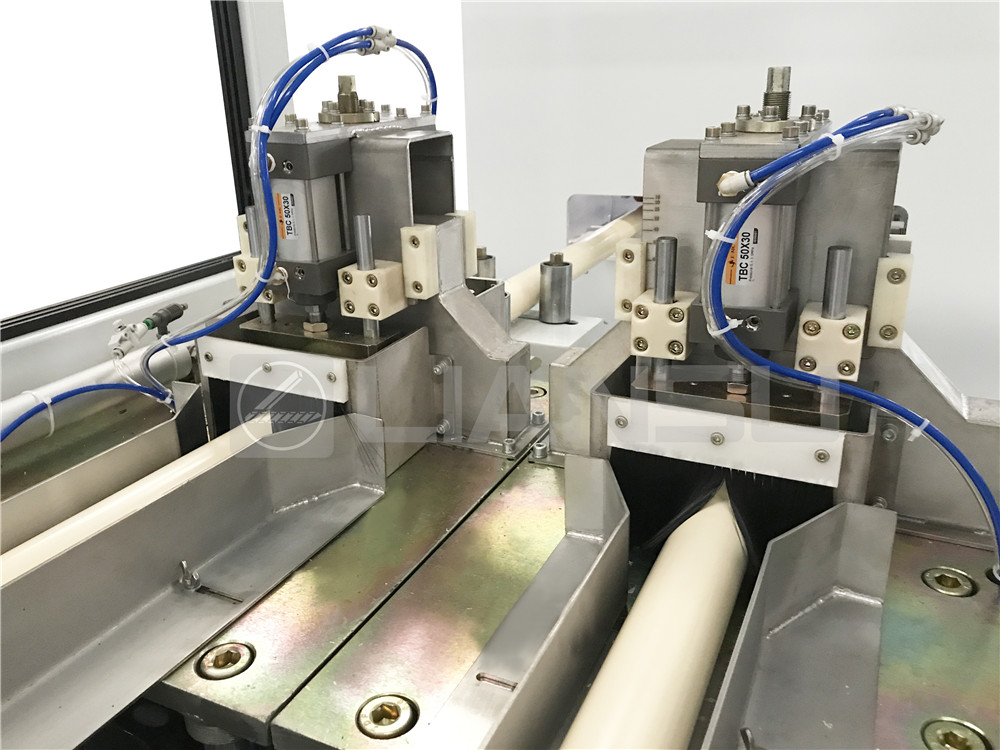

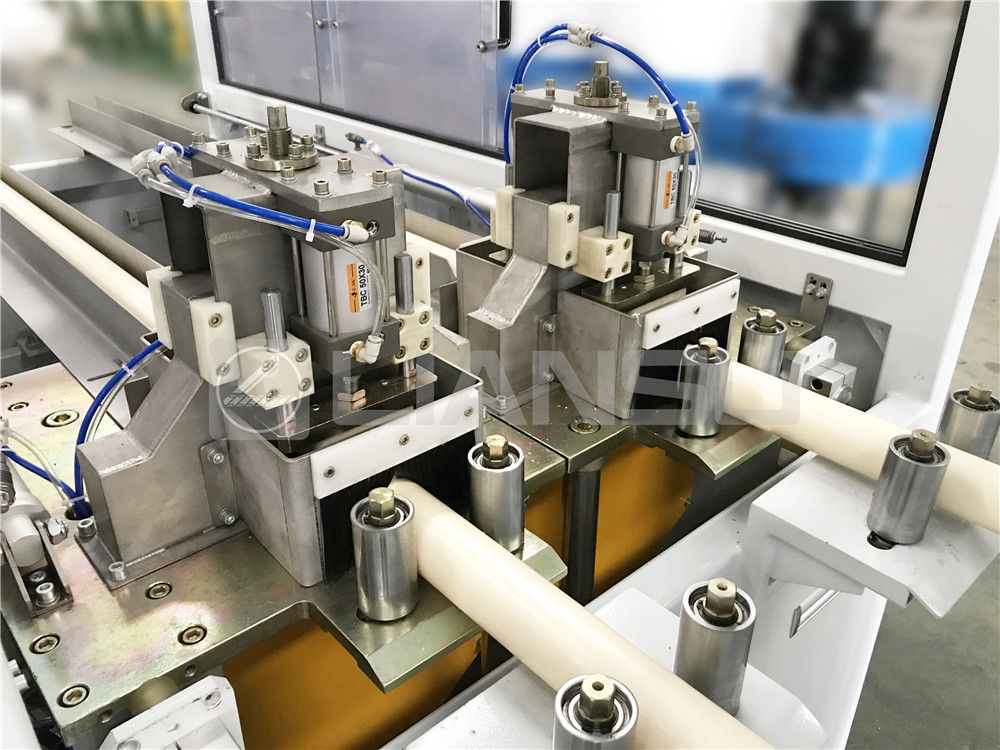

Haul-off Unit

Each hauling station is controlled independently, and independent permanent magnet synchronous servo motor scheme is adopted to ensure large speed regulation range. It can meet the requirements of fast hauling of small-sized pipe and slow hauling of large-size thick wall pipe at the same time, with stable speed and strict synchronization of each caterpillar.Cutter

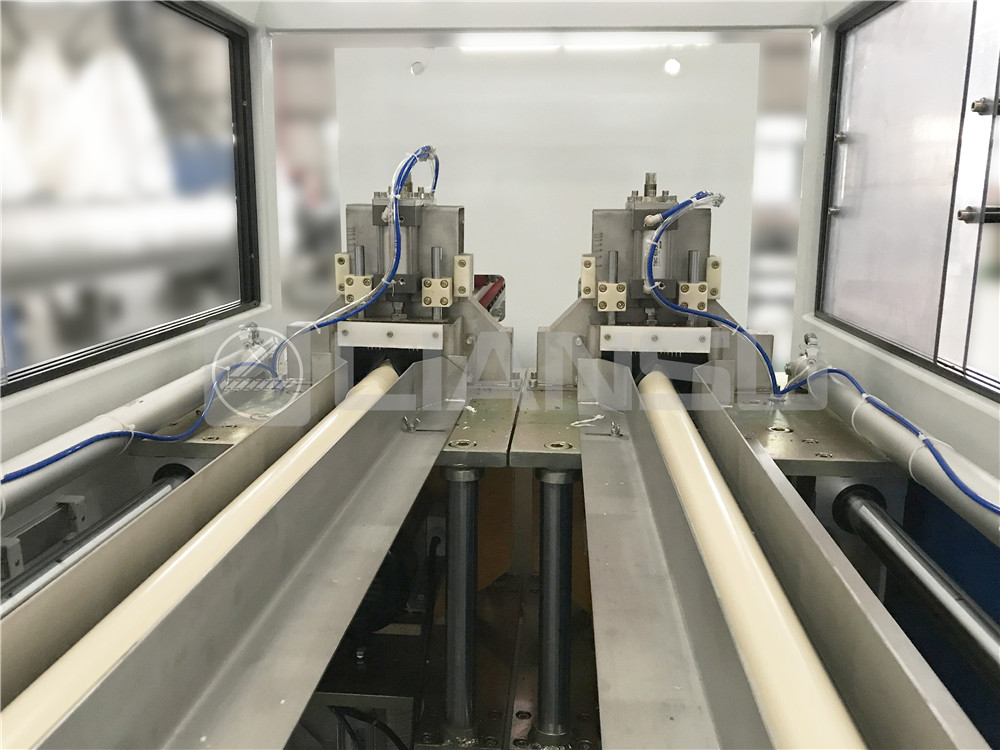

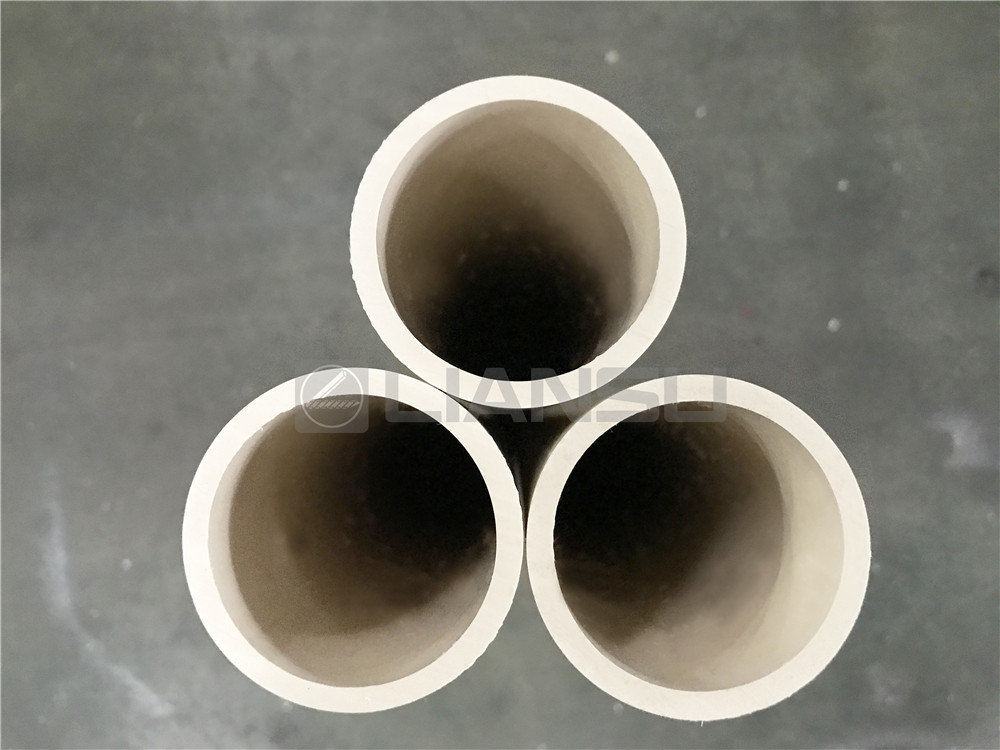

The double-station cutting is controlled independently and the series matching of swarfless cutting can help the production line to speed up and increase production, and greatly improve the site environment of the workshop.Sample

-

CPVC Double Pipe Extrusion Line