-

- The extruder adopts large L/D ratio screw and special permanent magnet synchronous servo motor for extruder to realize high production and energy saving.

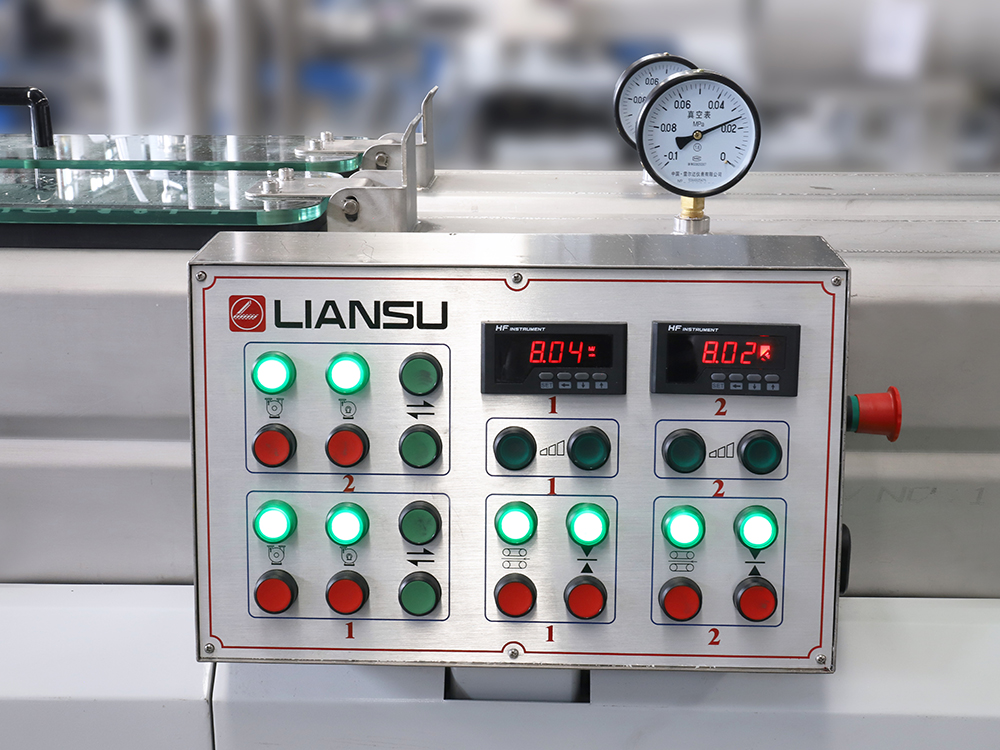

- Vacuum adopts frequency conversion closed-loop control, energy-saving and stable.

- The hauling adopts servo control to ensure stable production in large speed range.

- Equipped with on-line straight pipe, coil automatic packing mechanism, efficient and labour saving.

- Production data acquisition and analysis system can be selected to realize transparent production management.

-

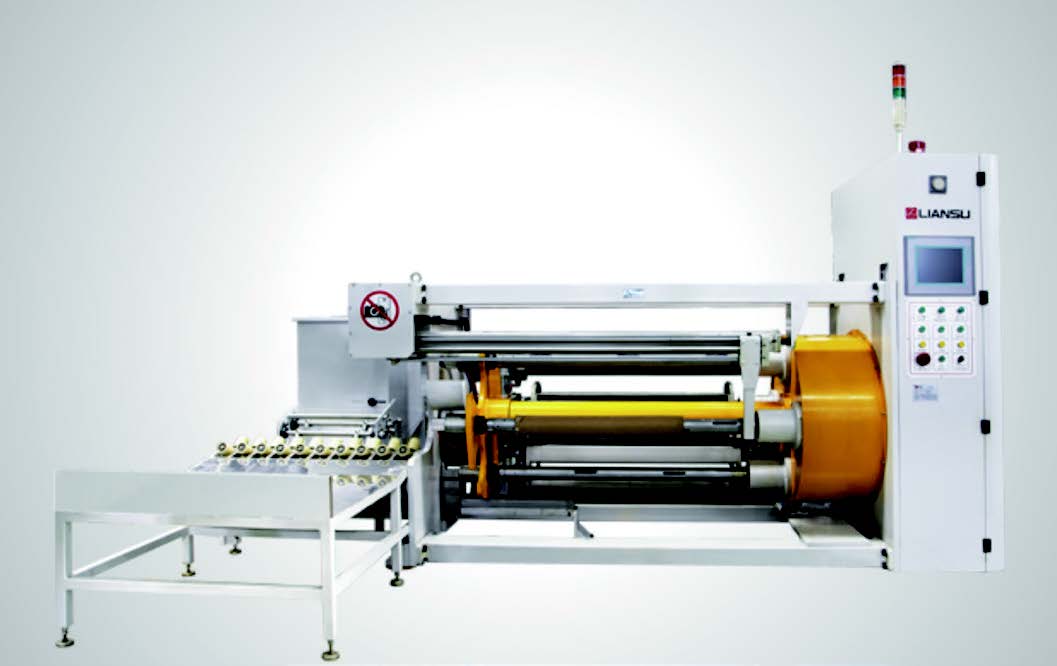

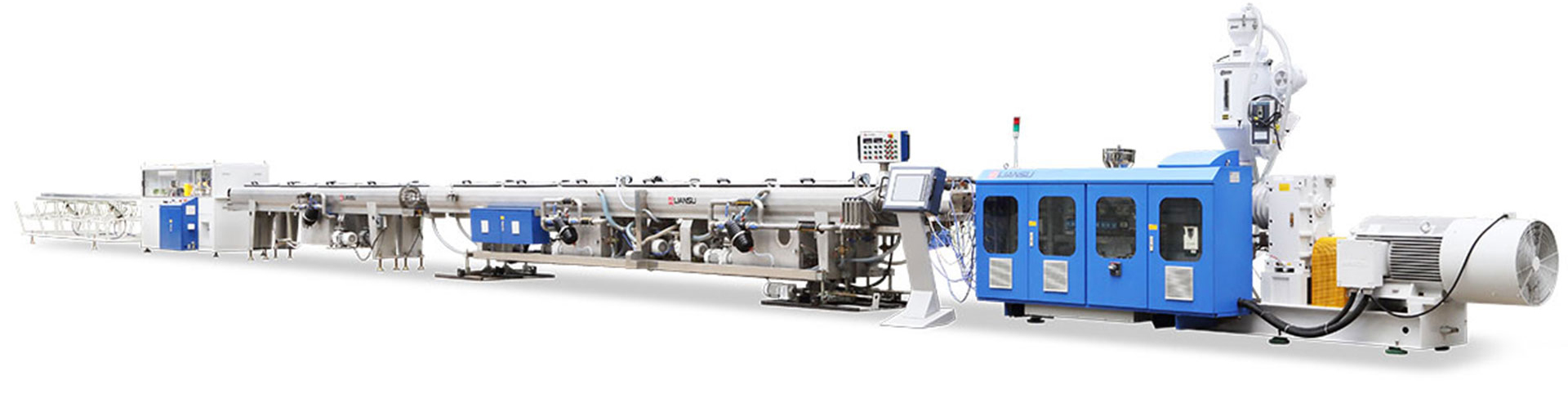

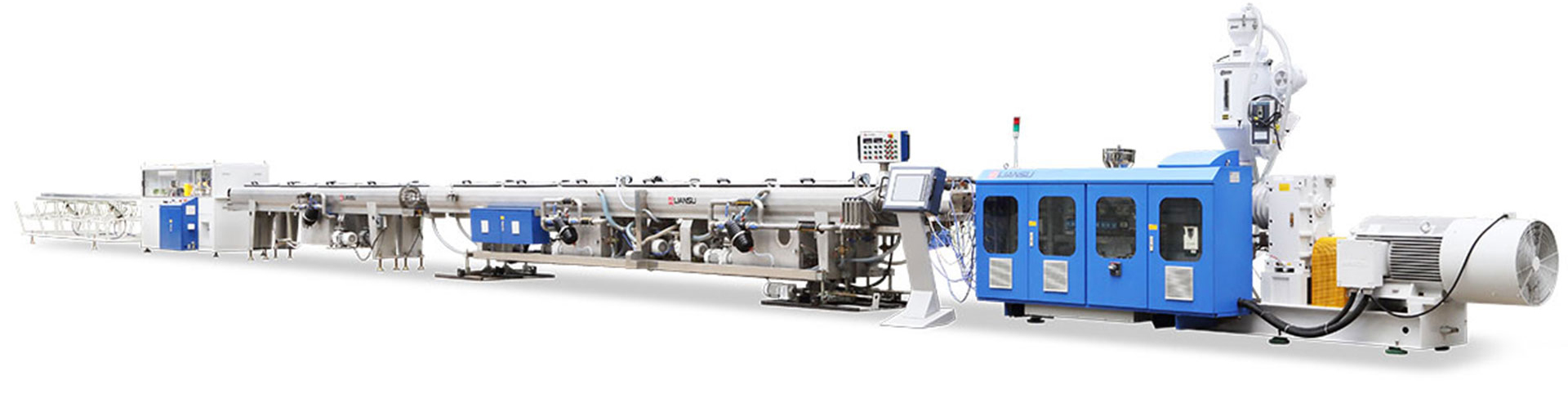

PPR Dual Pipe Production Line

Ø16-Ø32 mm

PIPE RANGE

25 m/min

MAX HAULING SPEED

75 kW

TOTAL INSTALLED POWER

300+250 kg/h

MAX OUTPUT

PPR Dual Pipe Production Line

Ø16-Ø32

PIPE RANGE, mm

25 m/min

MAX HAULING SPEED

75 kW

TOTAL INSTALLED POWER

300+250

MAX OUTPUT, kg/h

The extruder adopts large L/D ratio screw and special permanent magnet synchronous servo motor for extruder to realize high production and energy saving.

Vacuum adopts frequency conversion closed-loop control, energy-saving and stable.

The hauling adopts servo control to ensure stable production in large speed range.

Equipped with on-line straight pipe, coil automatic packing mechanism, efficient and labour saving.

Production data acquisition and analysis system can be selected to realize transparent production management.

The extruder adopts large L/D ratio screw and special permanent magnet synchronous servo motor for extruder to realize high production and energy saving.

Vacuum adopts frequency conversion closed-loop control, energy-saving and stable.

The hauling adopts servo control to ensure stable production in large speed range.

Equipped with on-line straight pipe, coil automatic packing mechanism, efficient and labour saving.

Production data acquisition and analysis system can be selected to realize transparent production management.

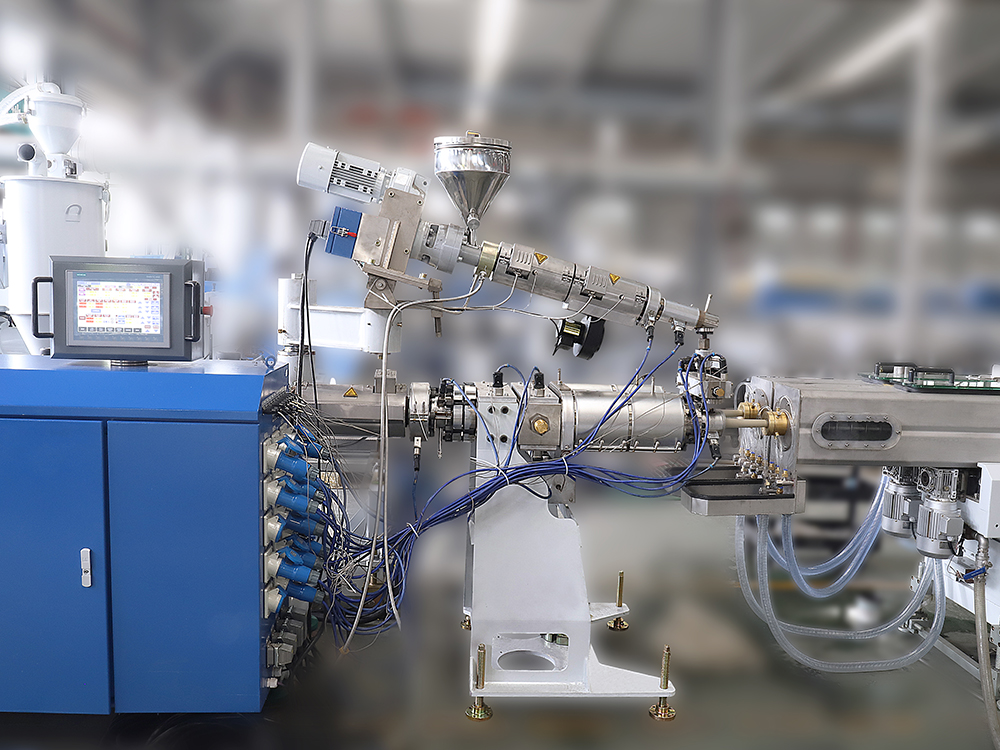

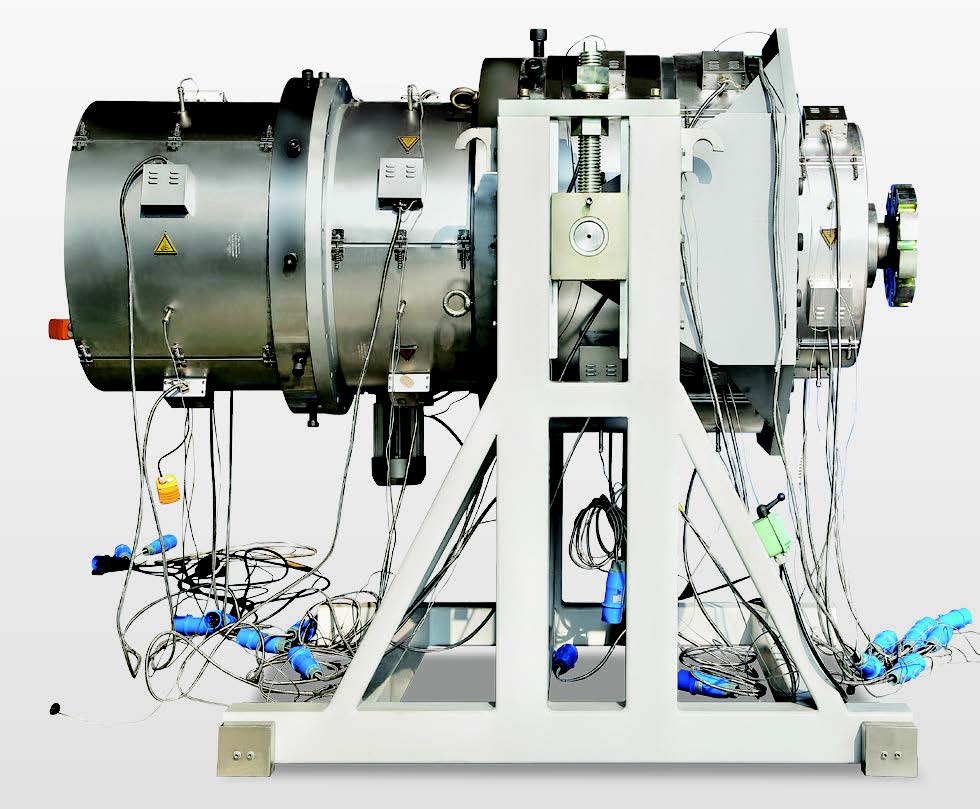

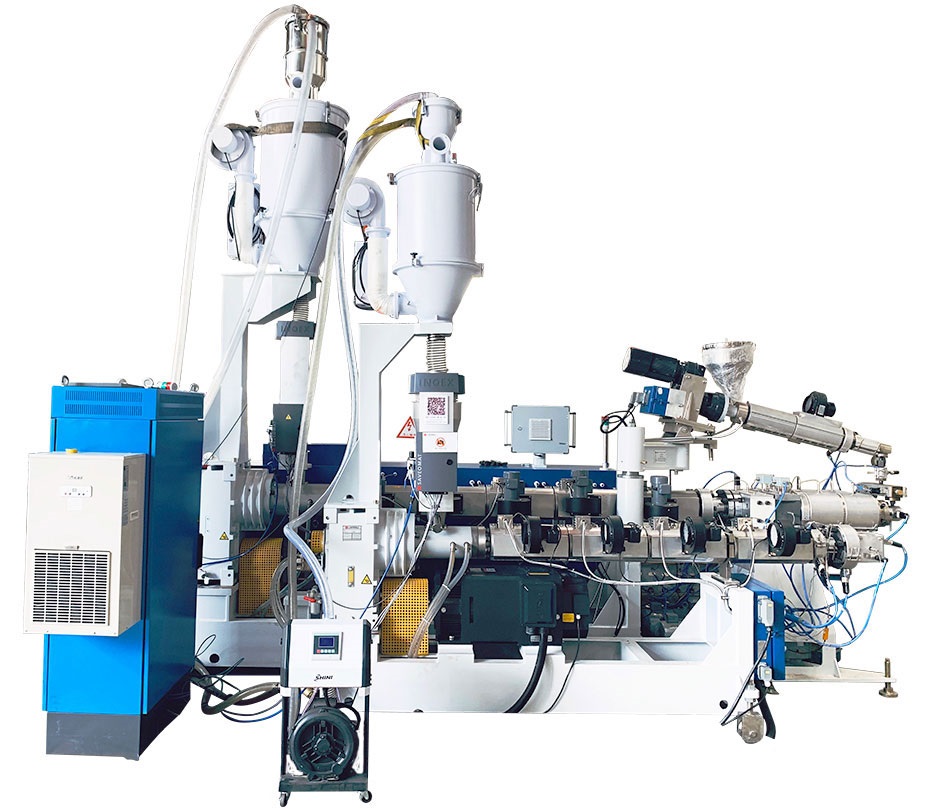

Extruder

>Single screw extruder, adopts large 40 L:D ratio high output screw design, matching with dedicated permanent magnet synchronous servo motor,low noise,the energy consumption of the whole line is low to 0.245kwh/kg.

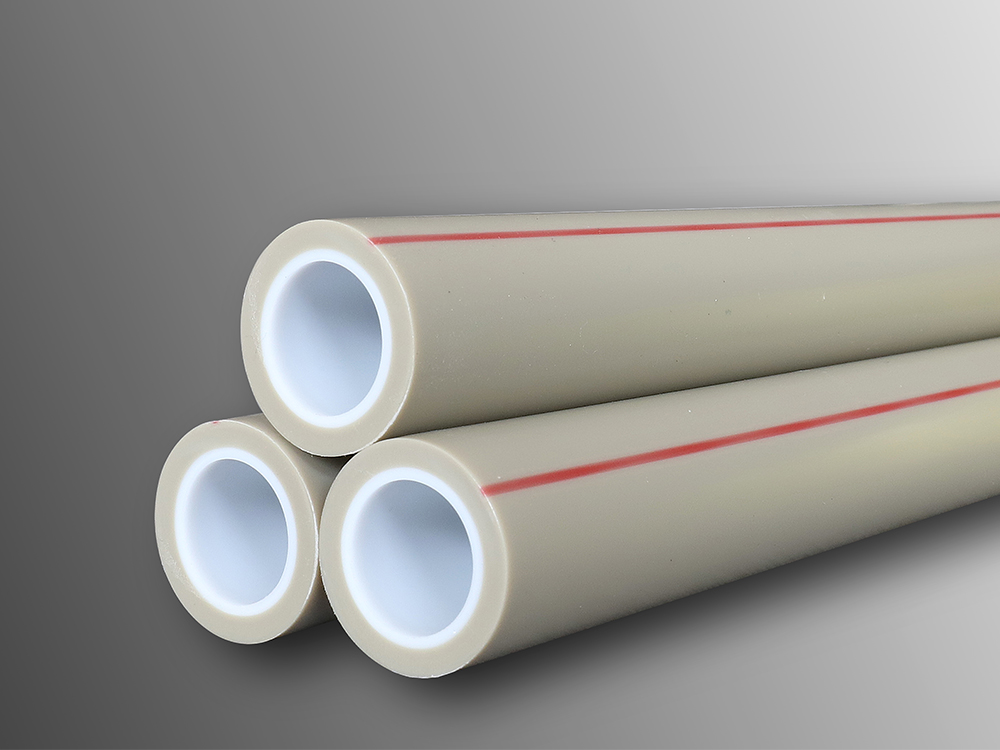

Doser of Masterbatch can be matched on line, the production of single layer and double-layer PPR pipes can be realized flexibly.

Extruder

Single screw extruder, adopts large 40 L:D ratio high output screw design, matching with dedicated permanent magnet synchronous servo motor,low noise,the energy consumption of the whole line is low to 0.245kwh/kg.

Doser of Masterbatch can be matched on line, the production of single layer and double-layer PPR pipes can be realized flexibly.Mould

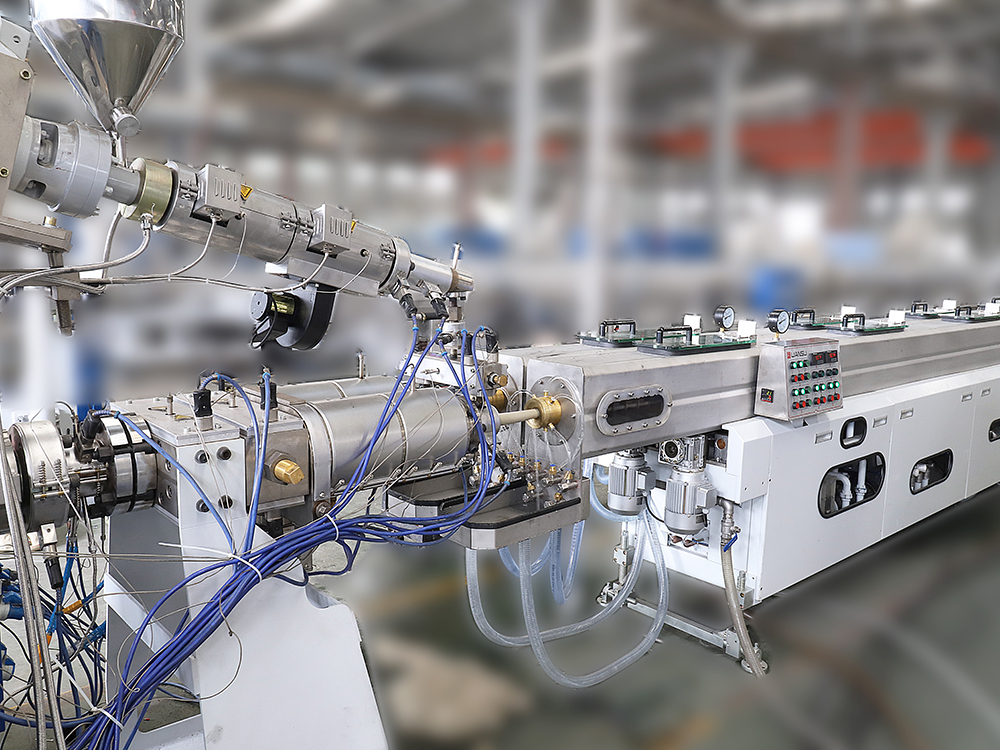

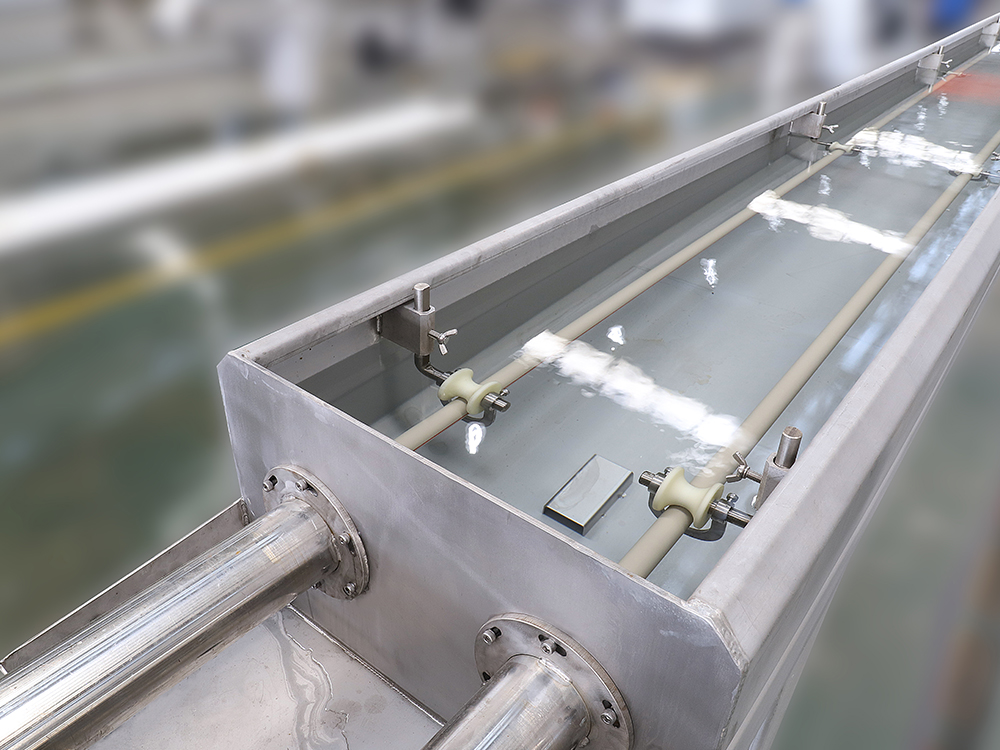

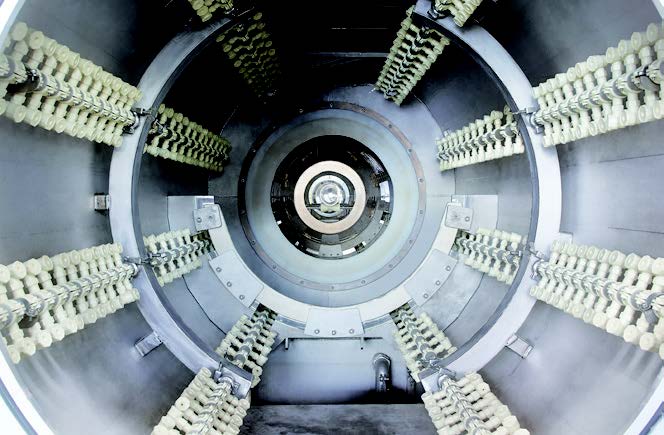

Single or multiple spiral die head structure can be selected for single layer or multi-layer structure, with uniform wall thickness, sleeve structure is adopted for setting die, forced water-cooling at inlet, high-speed and stable.Vacuum Tank

Double-station independent control, vacuum adopts negative pressure closed-loop automatic adjustment of vacuum degree, improves pipe production quality, reduces noise by more than 30dB, and saves energy by 40-90%.

It adopts contactless "water seal" vacuum molding.

Vacuum alarm, send signal to cut off waste pipe automatically.

Vacuum Tank

Double-station independent control, vacuum adopts negative pressure closed-loop automatic adjustment of vacuum degree, improves pipe production quality, reduces noise by more than 30dB, and saves energy by 40-90%.

It adopts contactless "water seal" vacuum molding.

Vacuum alarm, send signal to cut off waste pipe automatically.Haul-off Unit

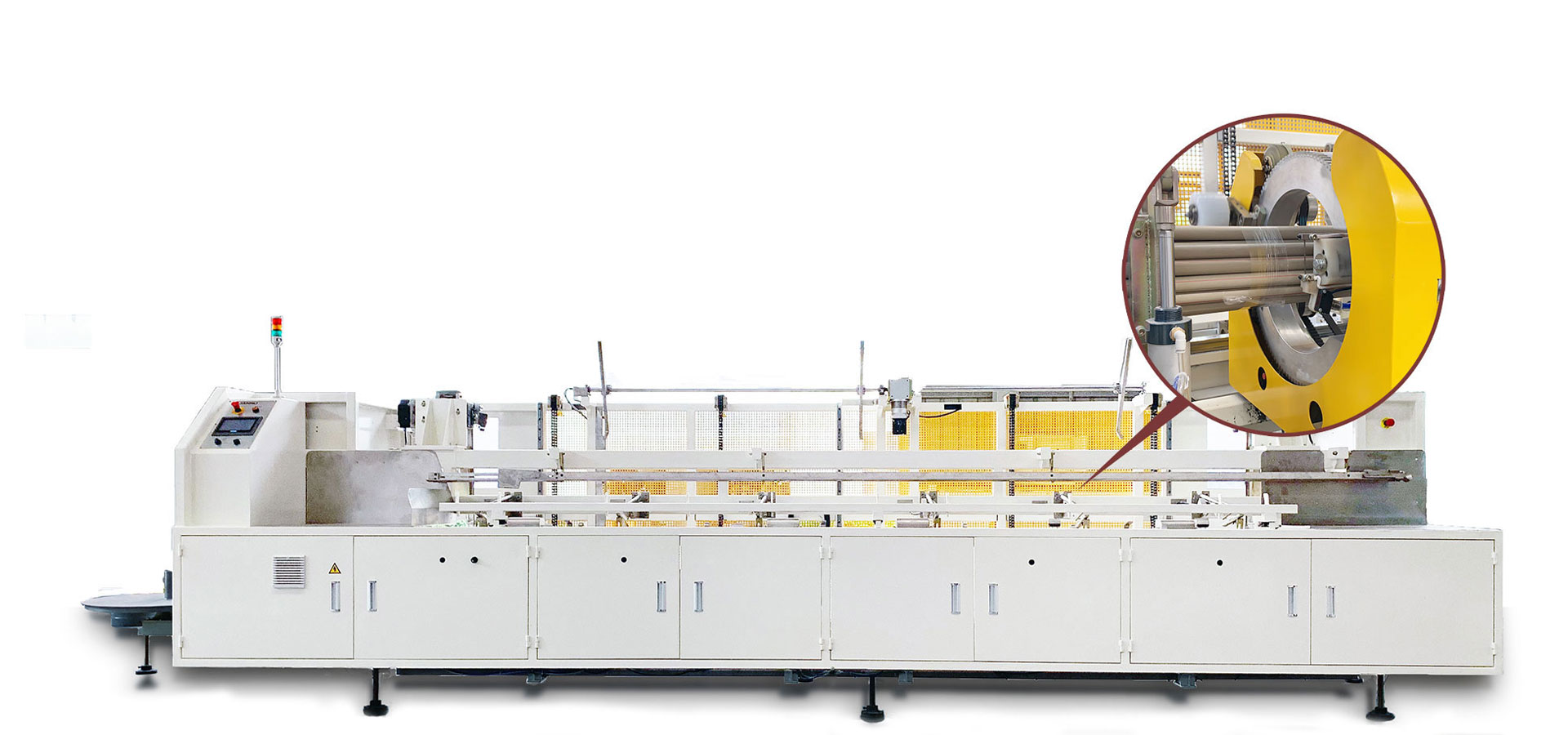

Each station is controlled independently. The haul-off unit adopts permanent magnet synchronous motor and high-speed hauling belt to ensure a stable speed regulation range of more than 50 times and realized high speed production.Cutter

Rotary swarfless cutter or flying knife swarfless cutter for option, precised cutting length control.

Cutter

Rotary swarfless cutter or flying knife swarfless cutter for option, precised cutting length control.On-line Auto Packaging Device

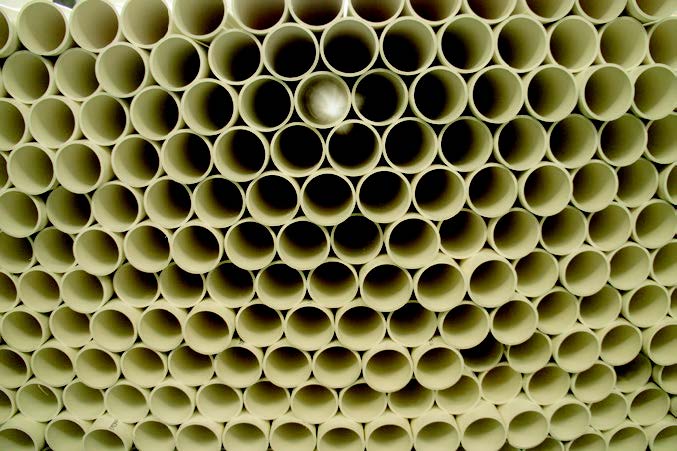

The whole series of online auto packing device realized on line auto bundling and bagging, on line weighing system before bundling ensured the quality of pipe before packing, greatly improve efficiency and reduce labor investment.

On-line Auto Packaging Device

The whole series of online auto packing device realized on line auto bundling and bagging, on line weighing system before bundling ensured the quality of pipe before packing, greatly improve efficiency and reduce labor investment.Sample

-

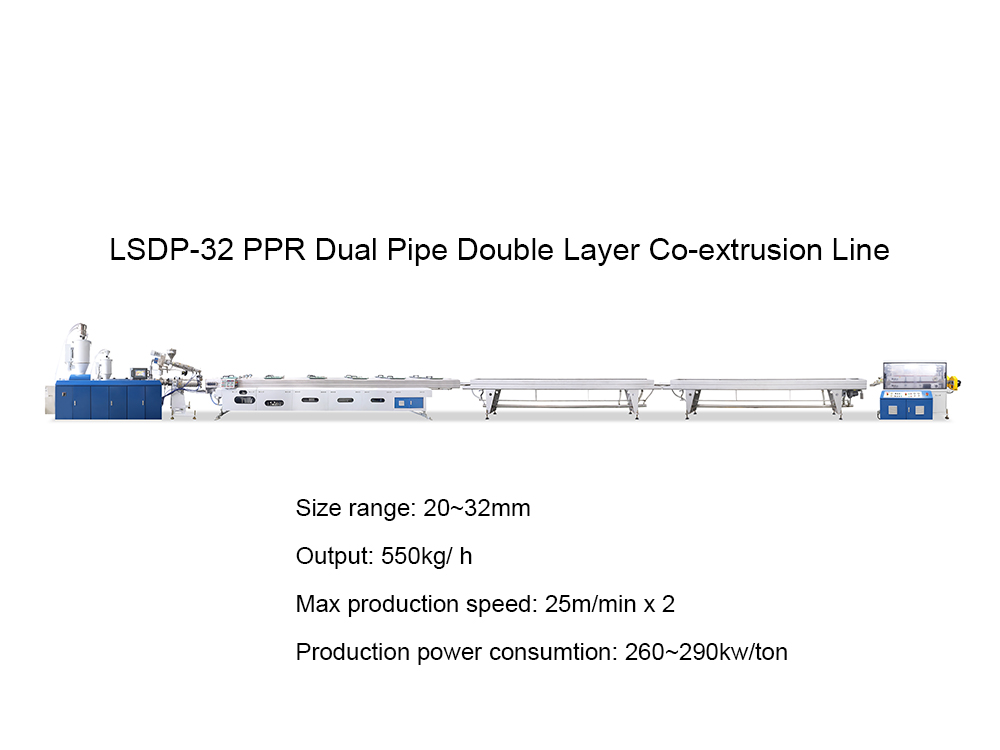

- Model

- Pipes, mm

- Speed, m/min

- Output, kg/h

- Length, m

- LSDP-32

- Ø16—Ø32

- 1-25

- 550

- 50

* Test and accept based on Liansu standard formula

- Model

- PIPE RANGE (mm)

- LINE SPEED (m/min)

- MAX OUTPUT (kg/h)

- LINE LENGTH (m)

- LSDP-32

- Ø16—Ø32

- 1-25

- 550

- 50

* Test and accept based on Liansu standard formula

-

Moscow, Russia