Liansu’s control system to improve transparency and efficiency. (CHINAPLAS 2021 Show Daily)

Guangdong Liansu Machinery Manufacturing Co., Ltd., a leading plastic extrusion and automation equipment manufacturer, is showcasing a variety of extrusion machines and also running production demos at CHINAPLAS 2021.

Notably, the Flexible FLEXCON+ Control and Information Integrated Operation Terminal of Plastic is making its world debut. Meanwhile, the two live demonstrations involve the Plastic Powder & Pellets Centralized Feeding System and the Plastic Extrusion Process for Energy Saving respectively.

Other highlight exhibits of the manufacturer include the PVC Pipe-specific parallel twin-screw extruder + extrusion die, the multi-layer HDPE pipe high-yield extruder + extrusion die, auxiliary extrusion equipment.

“This year, our exhibits are targeted to plastic extrusion products enterprises. The products are developed to address the needs of the market and the problems faced by users,” said Zhang Weiguang, General Manager of Liansu Machinery.

Real-time data increases production transparency

Taking the FLEXCON+ system as an example, Zhang Weiguang explained that the system extracts real-time data during the extrusion process and conducts multi-dimensional data analysis to make production management more transparent and efficient.

The system’s centralized feeding can improve product quality, reduce labour costs and help solve both the problems of environmental pollution during the extrusion process and the difficulty in recruiting workers.

Concurrently, the live demonstration of “dense phase” conveying of PVC powder features a host of advantages, including high conveying efficiency (solid-to-gas ratio>15:1), low air flow velocity, flexible pipe layout, and long conveying distance (up to 200 meters).

Suitable for PVC, PE and PPR materials, the system can solve various problems during the processes of conveying, storage, weighing and dosing, while providing customized turnkey engineering solutions.

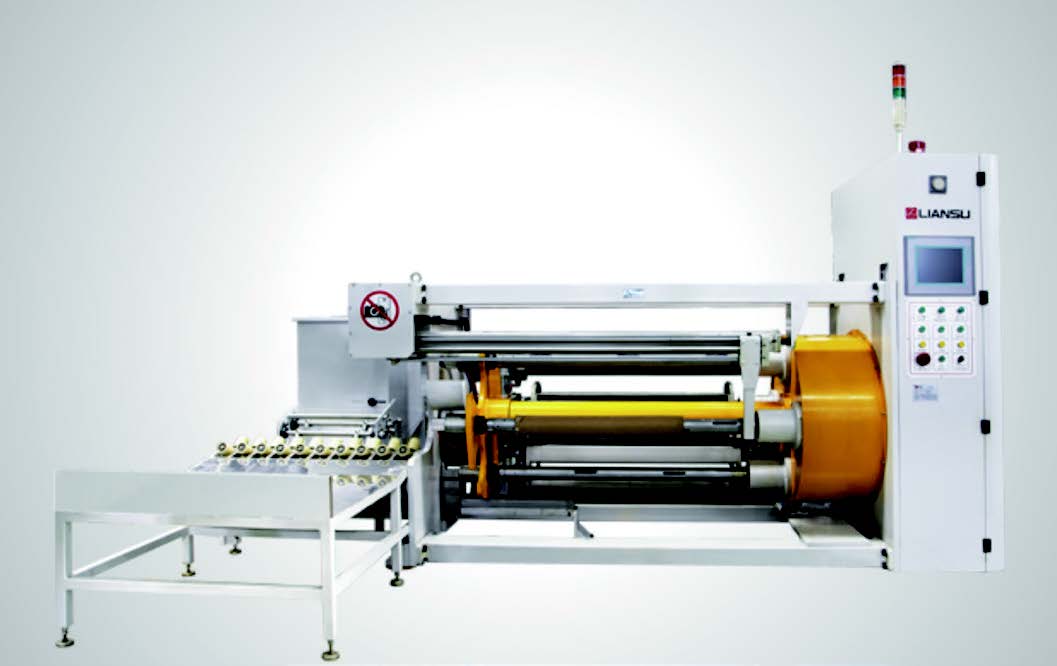

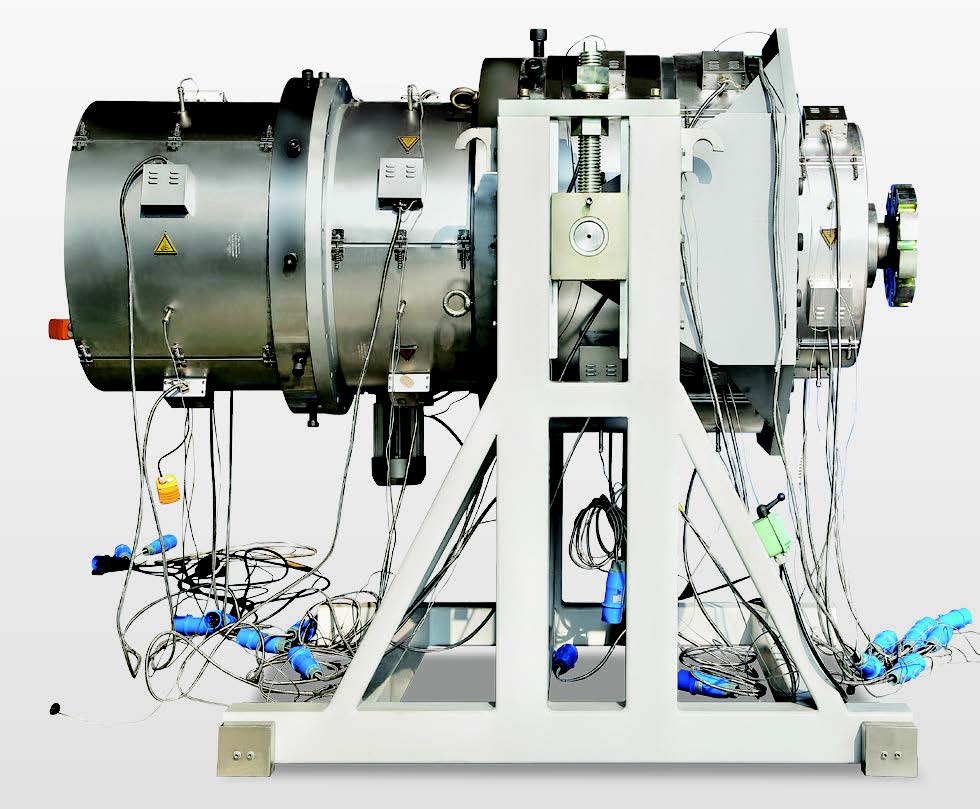

The parallel twin-screw extruder of Liansu Machinery.

Live demonstration features cutting-edge technology

Another on-site demonstration is the Plastic Extrusion Processing Energy-Saving System for production retrofit projects. The system is equipped with a special ultra-efficient permanent magnet synchronous motor and the latest synchronous motor and AC asynchronous motor.

During the live demonstration, visitors can see rapid adjustments made by the negative pressure vacuum shaping closed-loop of the plastic pipes, energy saving and noise reduction effects, as well as the track synchronization effect of the pipe traction.

In addition, whether they are single-screwed or parallel twin-screw extruders, the extruders on display feature large length-to-diameter ratio and high energy-saving. The screw design is optimized specifically for the material characteristics of plastic pipes to ensure high output and high product quality, emphasized Zhang Weiguang.

The auxiliary machine series is the pipe turning rack with meter weight control functions, which can dynamically weigh the weight of the pipe in real time, and continuously optimize the algorithm to control the meter weight of the pipe. “This helps to improve the quality of the pipes and save raw materials for extrusion,” he added.

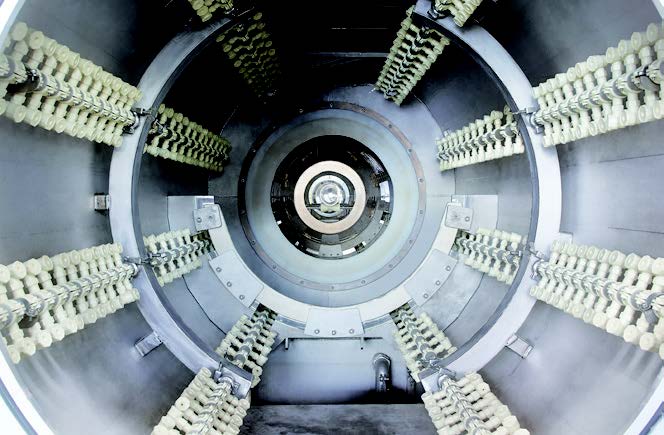

Liansu Machinery’s machine workshop.

Accelerate upgrade of equipment automation

Liansu Machinery, after going through a special year of 2020, has a series of exciting plans in place, including: speed up the upgrade of equipment automation in the next three years, deepen the integration of information and equipment, and strengthen human-machine interaction.

The manufacturer will also further develop equipment that can automatically judge and correct errors during the production process, with the goal of enhancing production with less manpower or unmanned production.

In 2021, following China’s “dual circulation development model”, Liansu Machinery is confident that it can achieve targets in both performance and profits, concluded Zhang Weiguang.

Booth: 8F45