Liansu: Efficient, Energy-saving, Automation and Informatization, Providing One-stop Extrusion Processing Ecological Chain.

【CHINAPLAS 2019 On-site Interview】Liansu: Efficient, Energy-saving, Automation and Informatization, Providing One-stop Extrusion Processing Ecological Chain

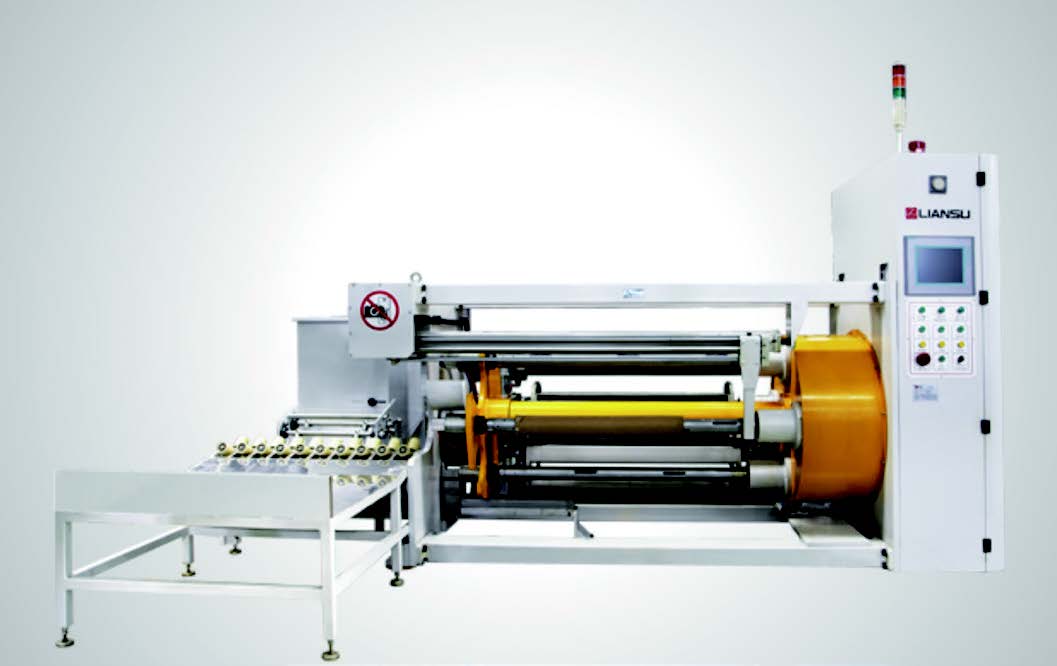

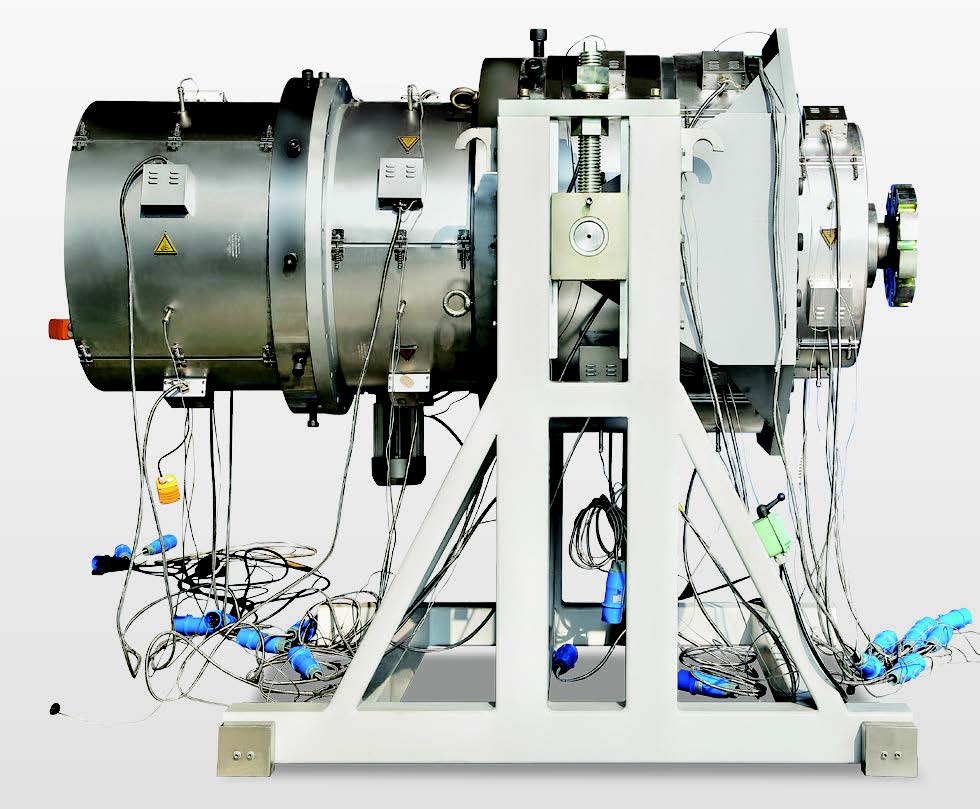

During the 2019 Chinaplas exhibition, Liansu focused on introducing efficient, energy-saving and informatization integrated pipe extrusion equipment, including 63PVC double-pipe production line, 32PPR double-pipe double-layer production line, data acquisition and analysis system and feeding system.

At the 2019 Chinaplas exhibition, there was a surge of people at the F51 booth in Hall 1.1.During the exhibition, Liansu focused on introducing efficient, energy-saving and informatization integrated pipe extrusion equipment.According to Mr. Huang, Technical Manager of Guangdong Liansu Machinery Manufacturing Co., Ltd., the highlights of the exhibition include 63PVC double-pipe production line, 32PPR double-pipe double-layer production line, data acquisition and analysis system and feeding system, which attracted many customers to inquire.

Mr. Huang, Technical Manager of Guangdong Liansu Machinery Manufacturing Co., Ltd.

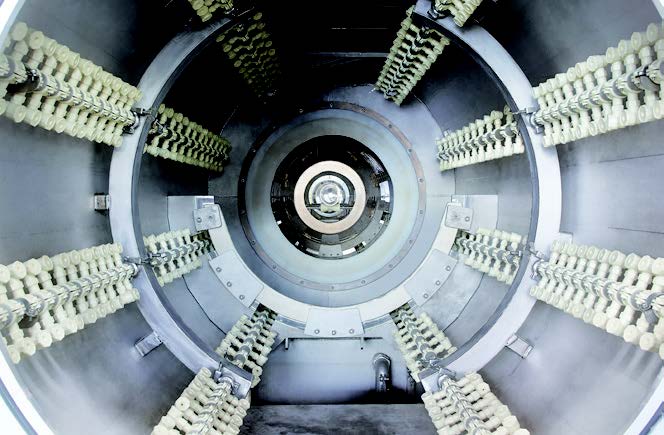

The main points of Liansu exhibition stand are as follows: High-efficiency and high-yield main machine adopts large L/D ratio to ensure line speed up to 2×25 m/min. The vacuum tank adopts negative pressure closed-loop control scheme, which saves 70-80% energy and greatly reduces noise. The production line adopts highly customized permanent magnet servo motor from main machine to downstream, which reduces energy consumption by 15%. On-site equipment adopts central feeding system to convey material. Real-time acquisition and analysis of all data in each link of the production line.’ Mr. Huang said.

The above highlights fit well with the striking slogans on the screen - High efficiency, Energy saving, Automation and Informatization, Providing you with a one-stop extrusion processing ecological chain.

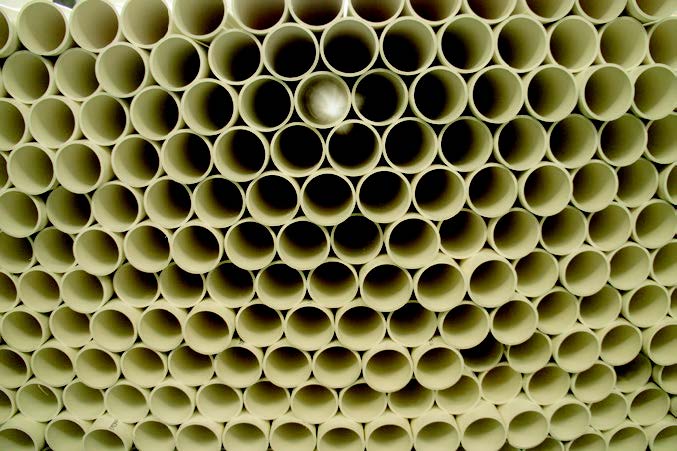

He also said, plastics is one of the most important markets for Liansu Machinery. Facing the market environment of stable market demand, increasing production costs and higher product quality requirements, in recent years, most domestic terminal manufacturers have changed greatly in equipment selection and purchase. Most large pipeline manufacturers are concerned about how to improve production automation, improve efficiency and reduce energy consumption, and produce up-to-standard pipes according to standard requirements. That has facilitated the development of Liansu Machinery towards high efficiency, energy saving, automation, informatization and other directions.

In this exhibition, Mr. Huang also realized that: compared with the price, customers now pay more attention to quality and details. This strengthened the determination of Liansu to do well in details and provide stable products. To manufacture a machine, we must move forward steadfastly.

In addition, he also mentioned the industry's future trend of differentiation: The more high-end customers, the clearer the requirements they put forward. According to the current situation, with the upgrading of the industry, homogeneous competition is very fierce, so we must take a differentiated line, breakthrough from three aspects: efficiency, energy consumption and stability.