-

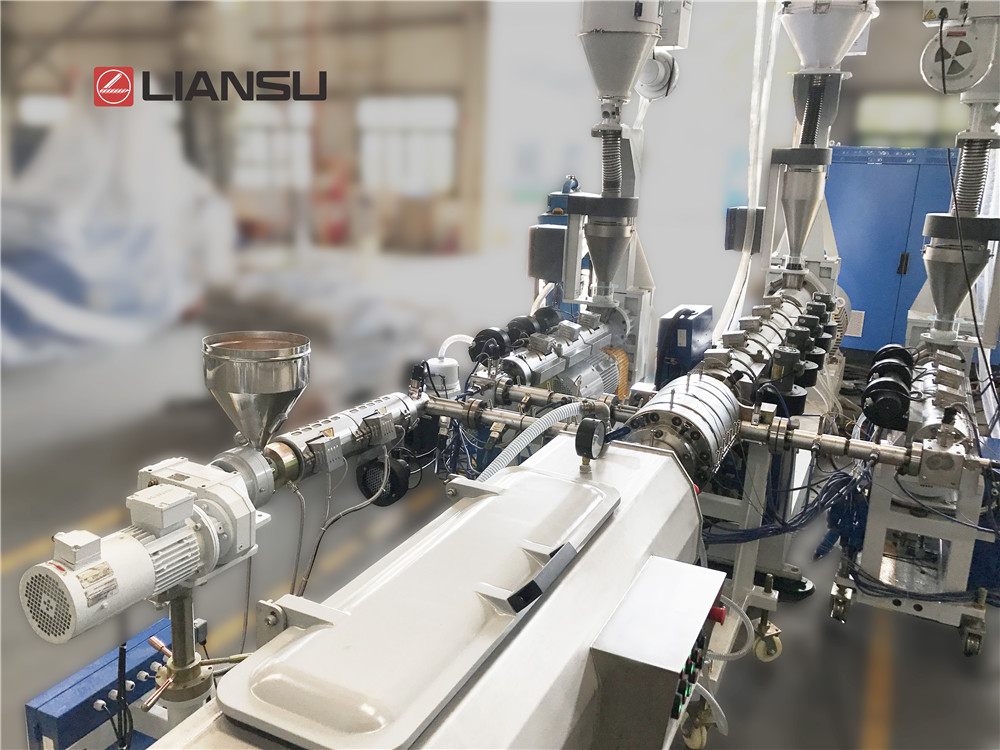

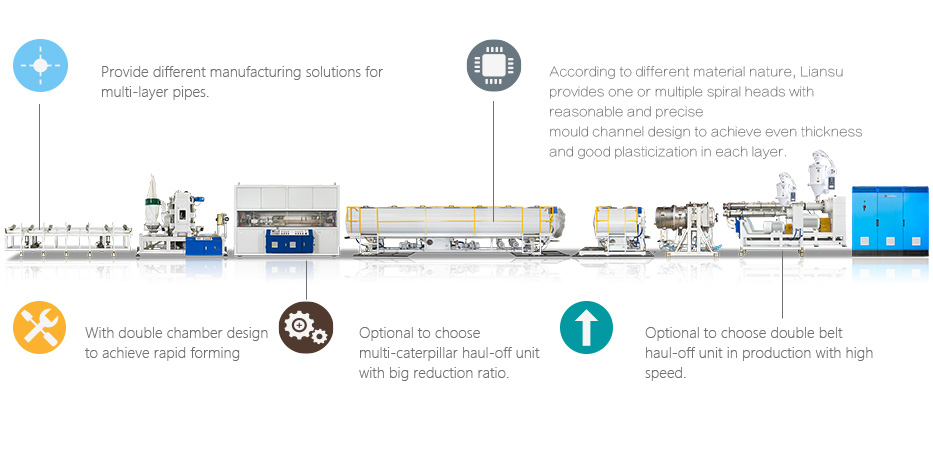

- Provides various prodution solutions for multilayer pipes.

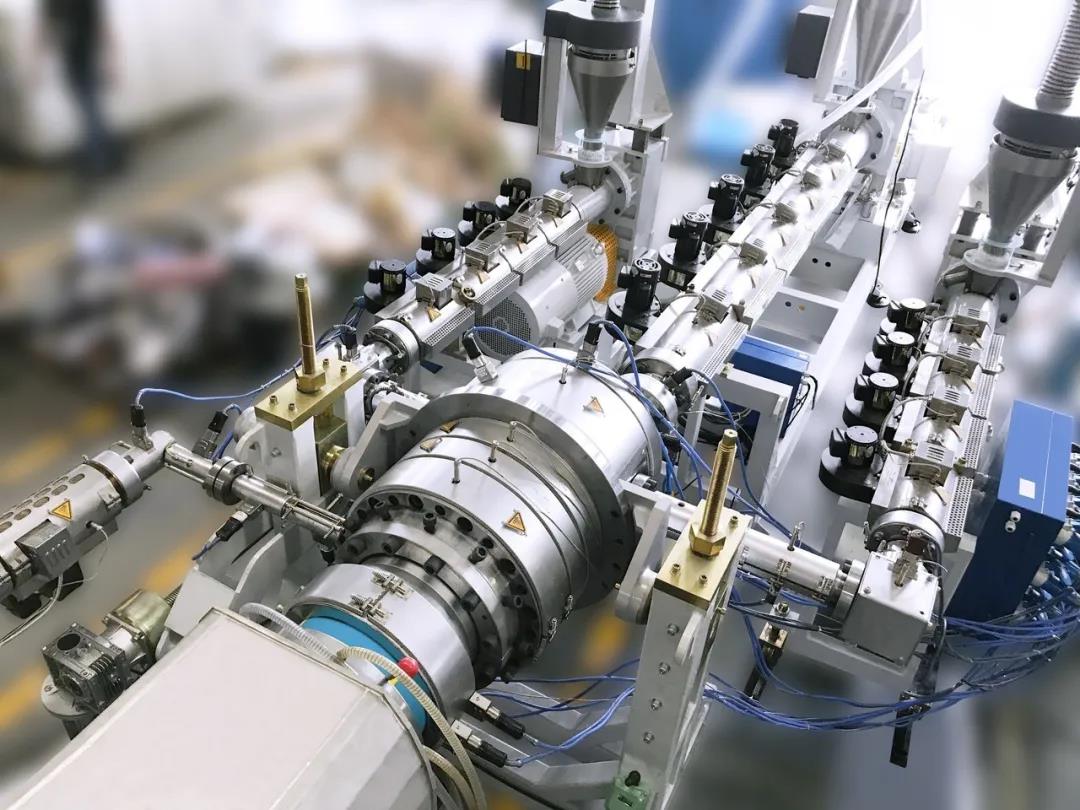

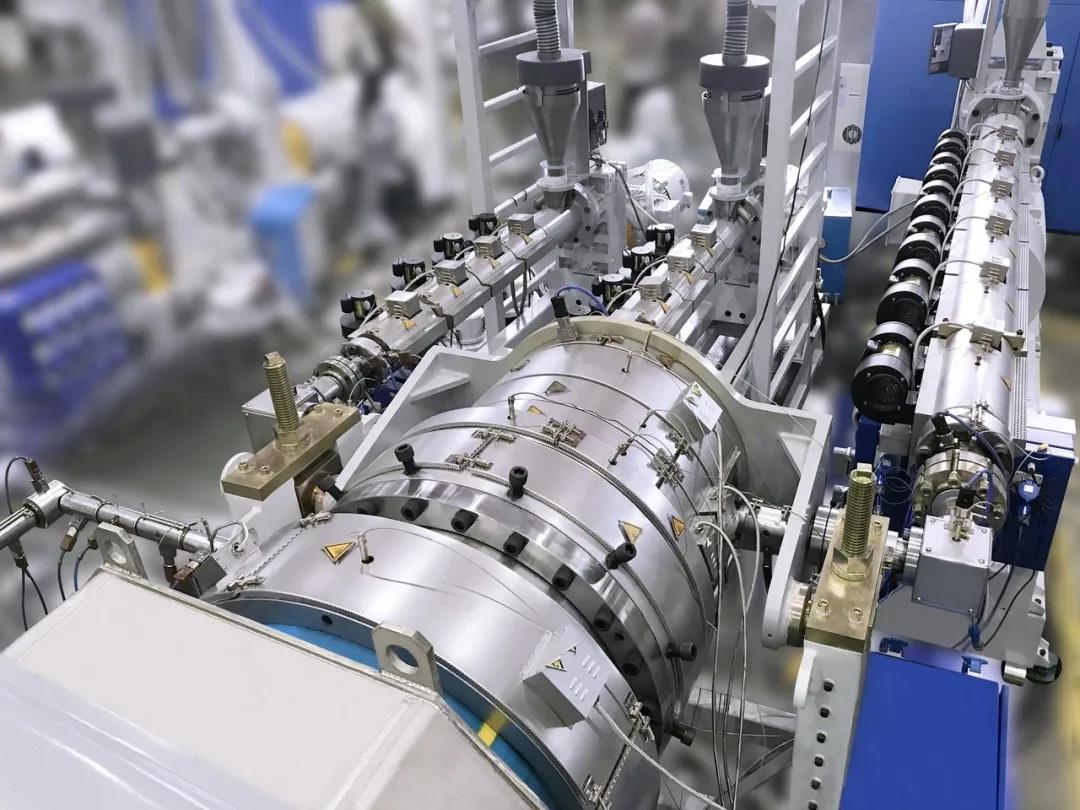

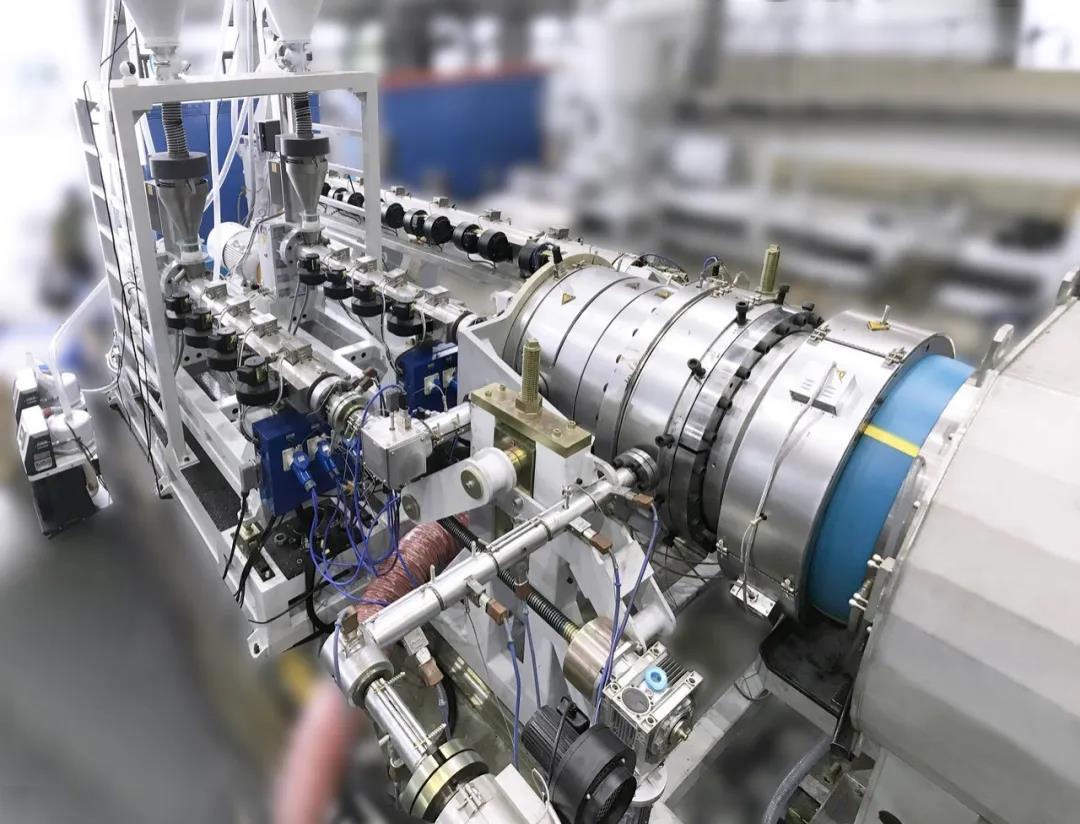

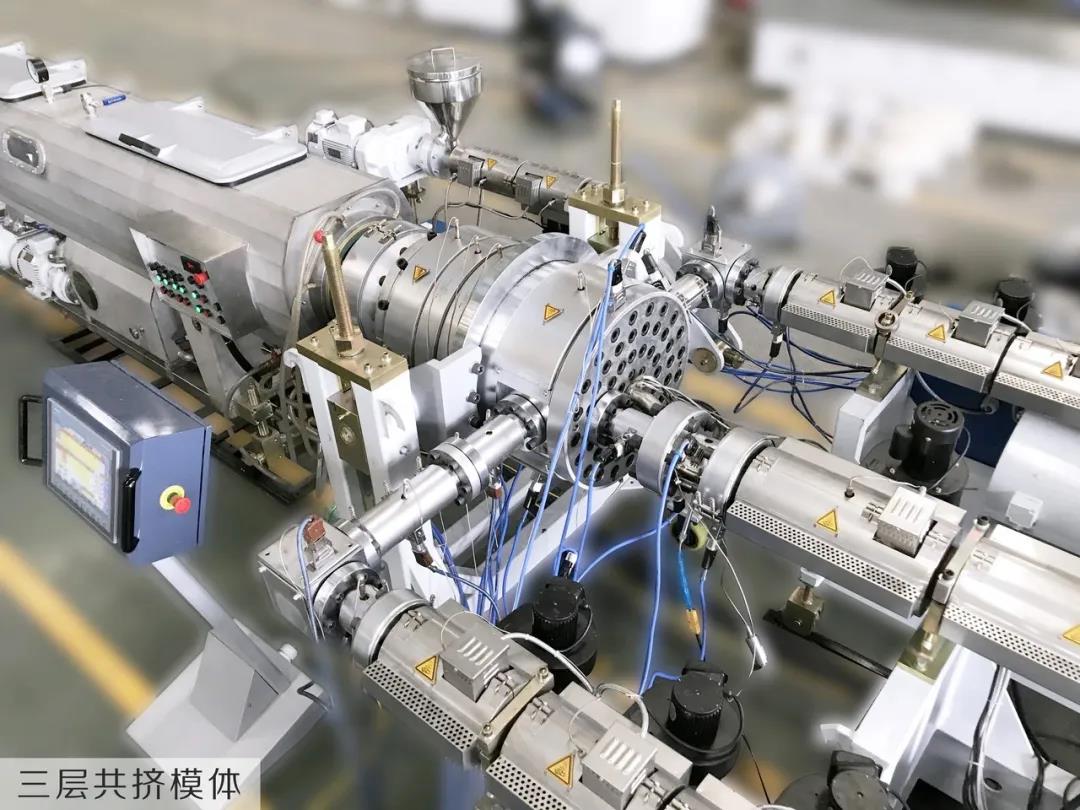

- Depending on the the material, Liansu offers one or more spiral die heads with reasonable and precise mold channel design to achieve uniform thickness and good plasticization in each layer.

- Dual-chamber design for fast forming.

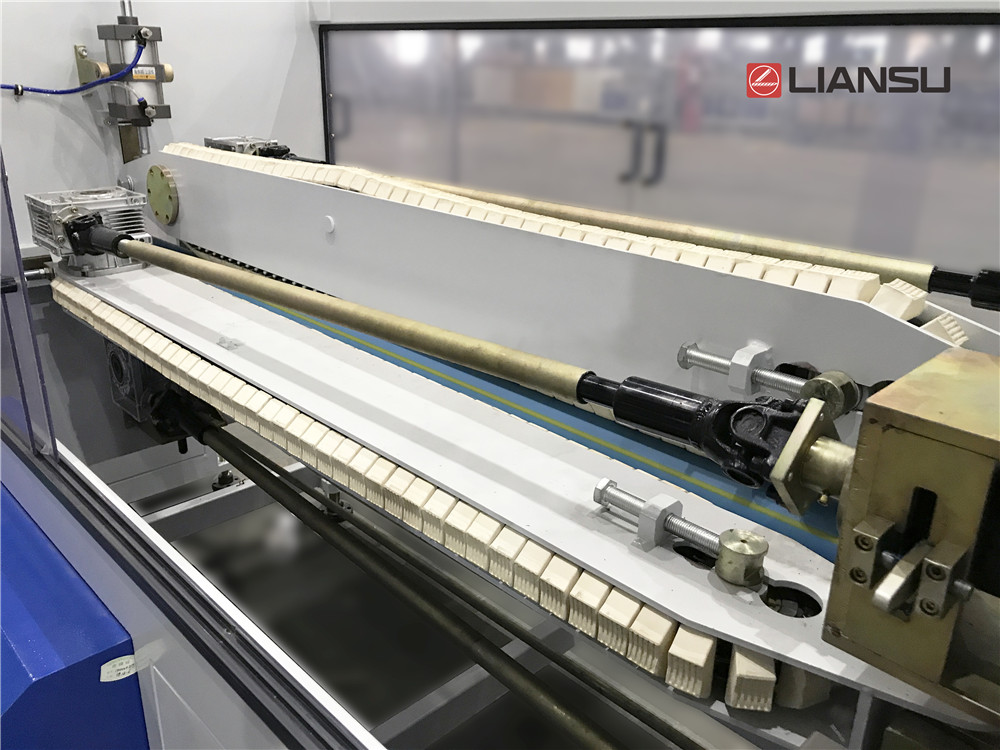

- Optionally selectable high speed dual-belt pulling units.

- Additionally, you can choose multi-track towing devices with a large gear ratio.

- Dual hydraulic design ensures neat, chipless pipe cutting.

-

- Model

- Diameter, mm

- Output, kg/h

- Speed, m/min

- Co-extrusion

- LSP-63PE

- Ø16-Ø63

- 300

- 25

- 1-3 Layer

- LSP-110PE

- Ø20-Ø110

- 300

- 14

- 1-3 Layer

- LSP-160PE

- Ø40-Ø160

- 600

- 8

- 1-3 Layer

- LSP-250PE

- Ø50-Ø250

- 600

- 6.5

- 1-3 Layer

* Test and accept based on Liansu standard formula

- Model

- Pipe Range, mm

- Max Output, kg/h

- Line speed, m/min

- Co-extrusion

- LSP-63PE

- Ø16-Ø63

- 300

- 25

- 1-3 Layer

- LSP-110PE

- Ø20-Ø110

- 300

- 14

- 1-3 Layer

- LSP-160PE

- Ø40-Ø160

- 600

- 8

- 1-3 Layer

- LSP-250PE

- Ø50-Ø250

- 600

- 6.5

- 1-3 Layer

* Test and accept based on Liansu standard formula

-

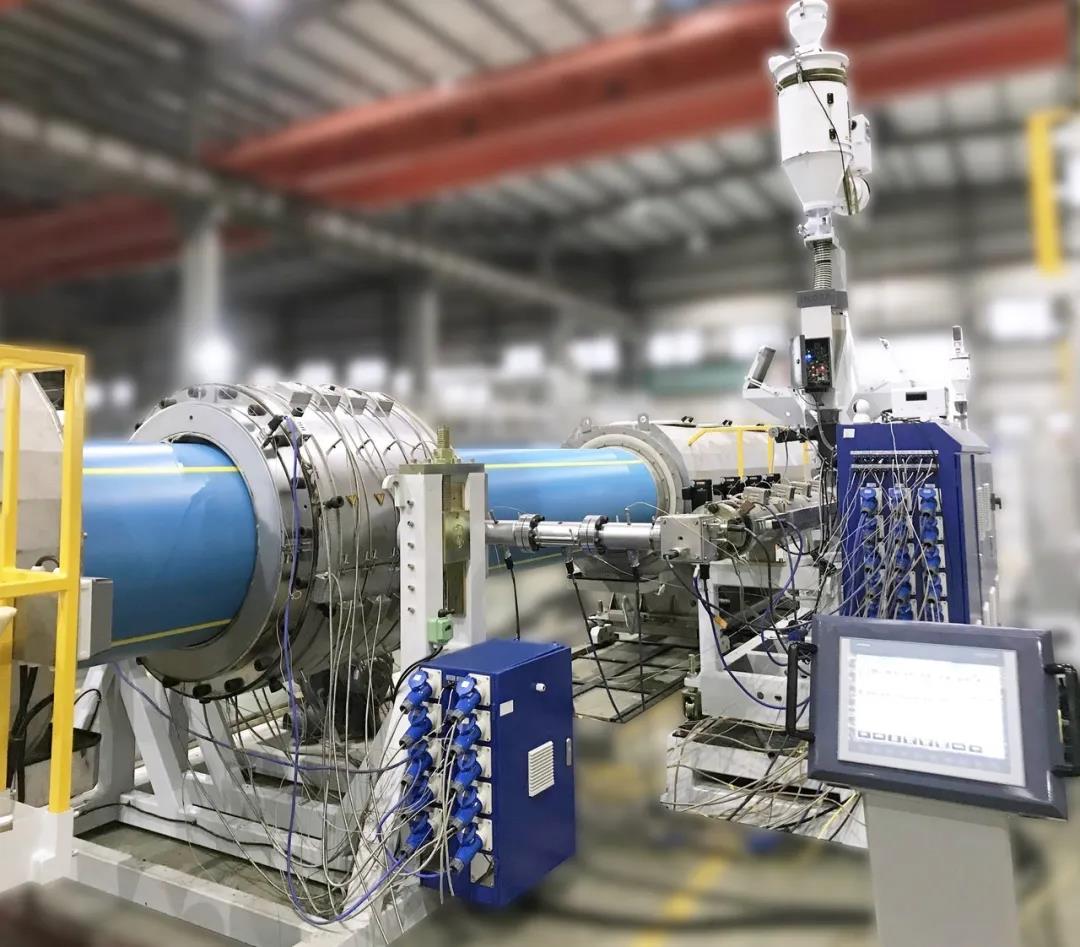

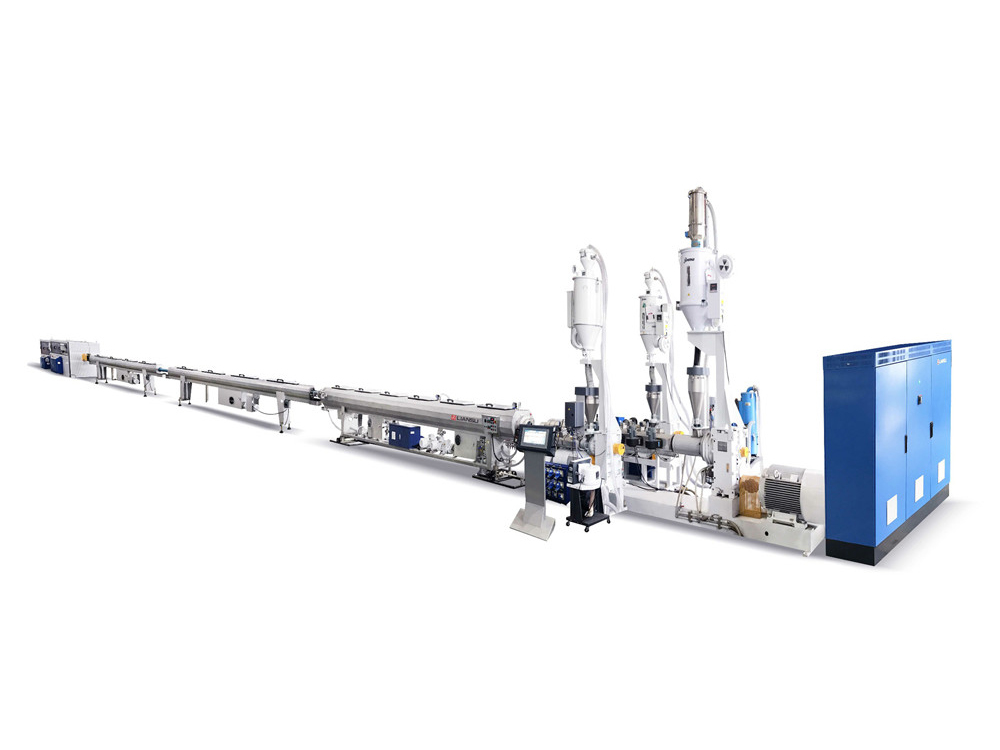

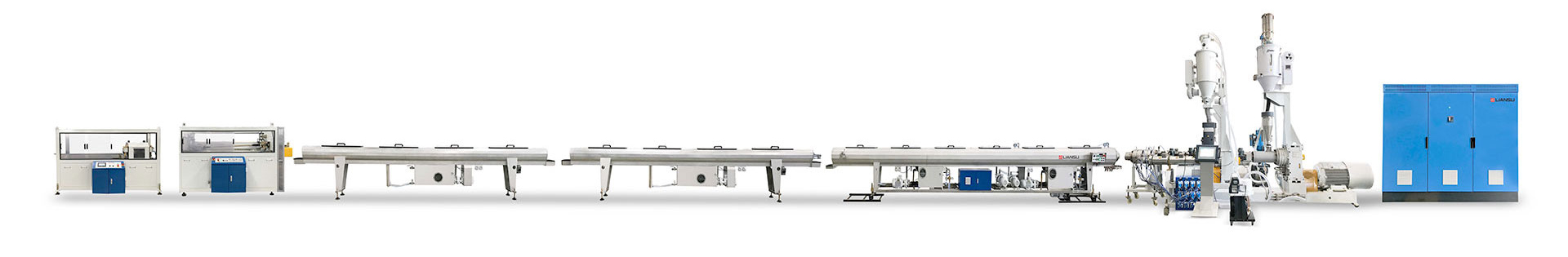

110mm HDPE Three Layer Pipe Production Line

Ø16-Ø250

Pipe Range, mm

25 m/min

Line Speed

1-3 Layer

Co-extrusion

600 kg/h

Max Output

110mm HDPE Three Layer Pipe Production Line

Ø16-Ø250

Pipe Range, mm

25 m/min

Line Speed

1-3 Layer

Co-extrusion

600 kg/h

Max Output

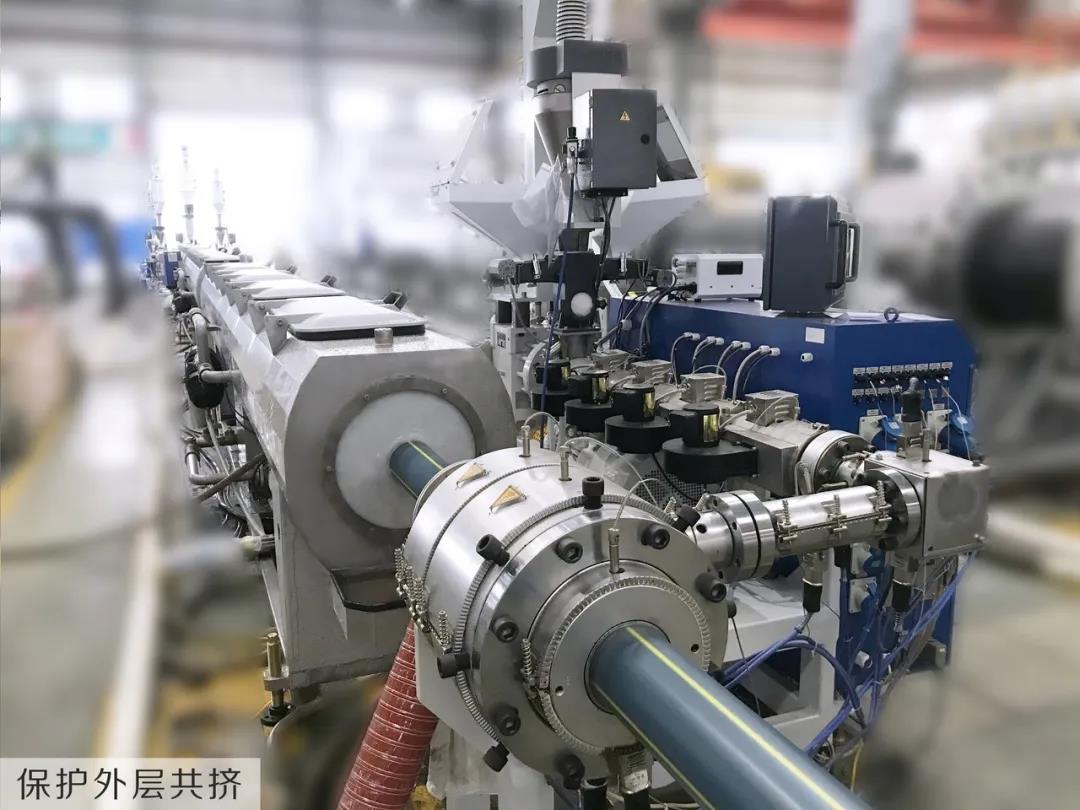

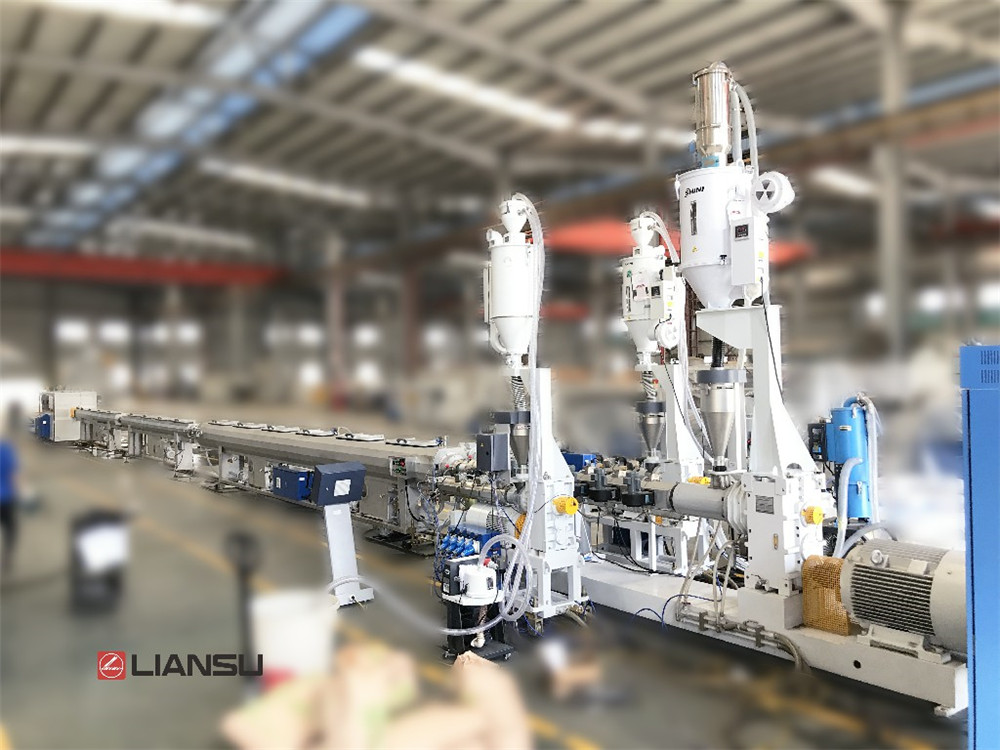

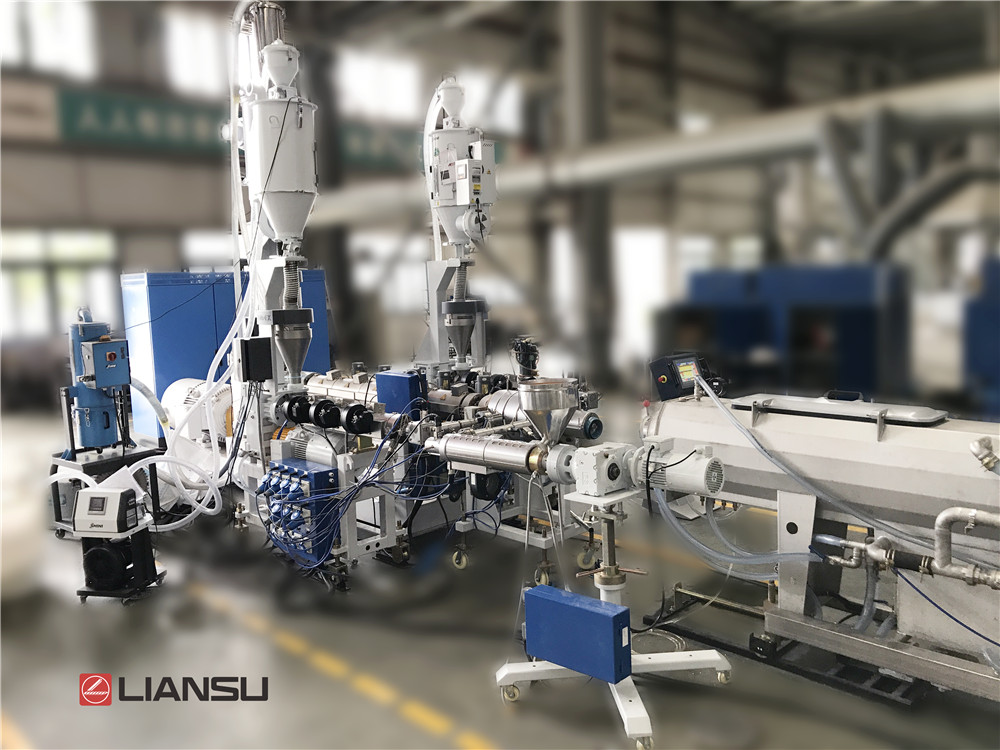

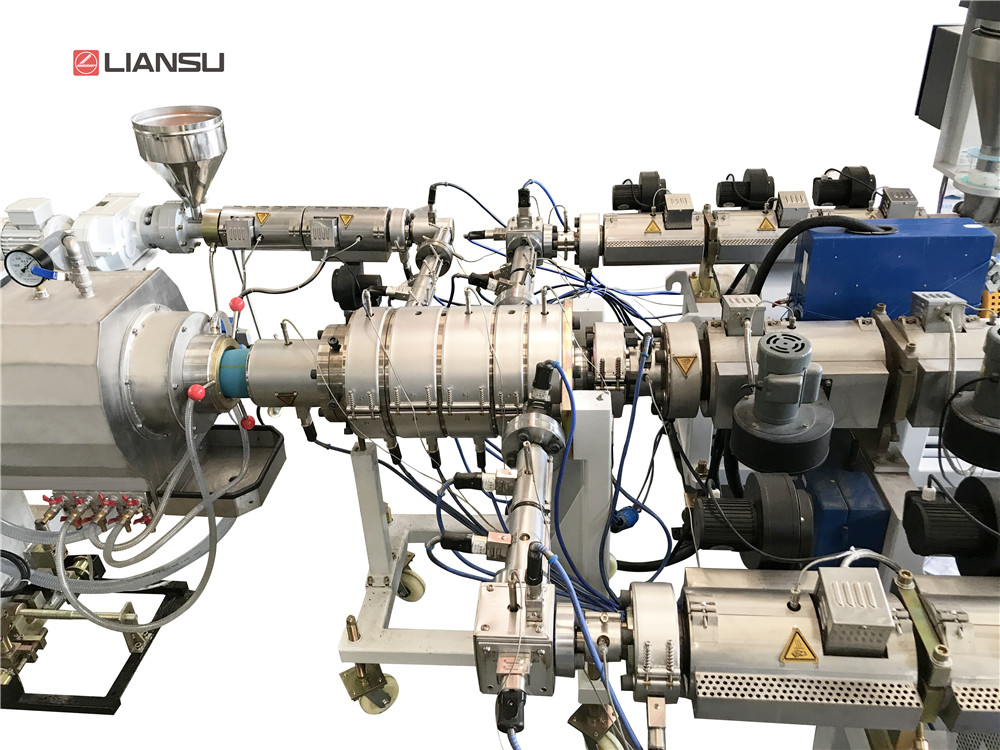

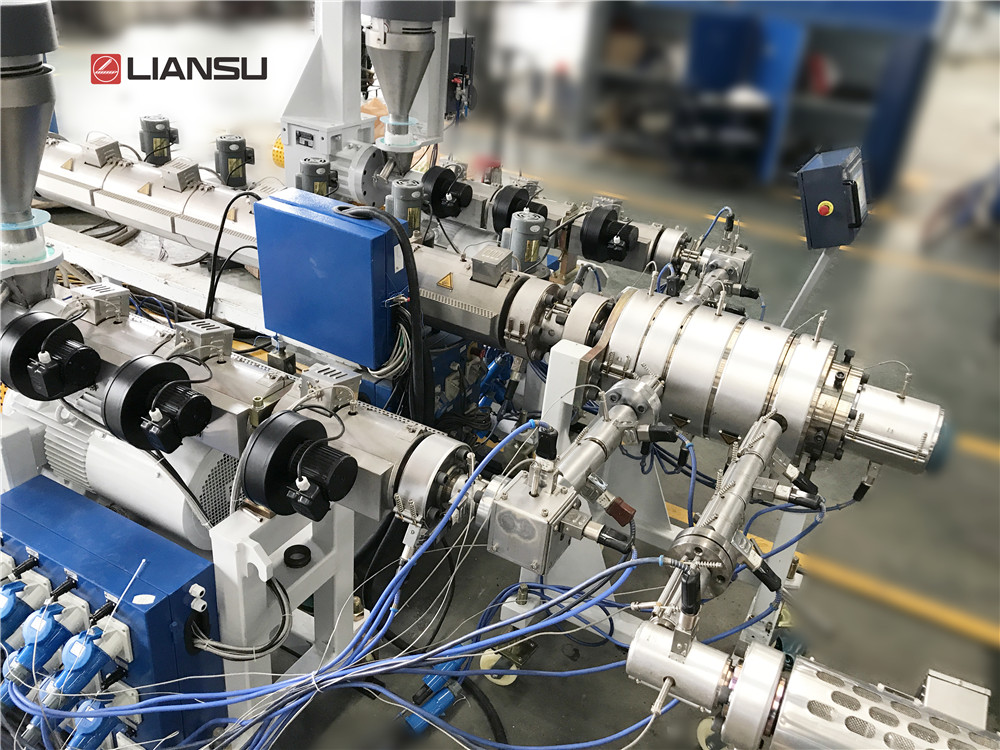

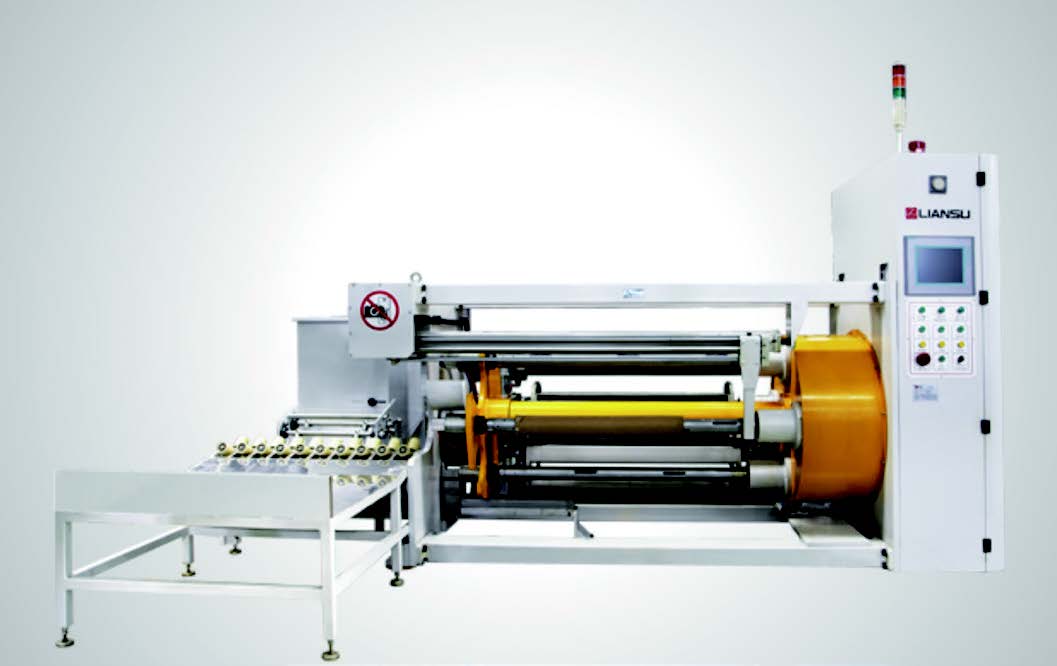

The extruder adopts large L/D ratio screw and special permanent magnet synchronous servo motor for extruder to realize high production and energy saving.

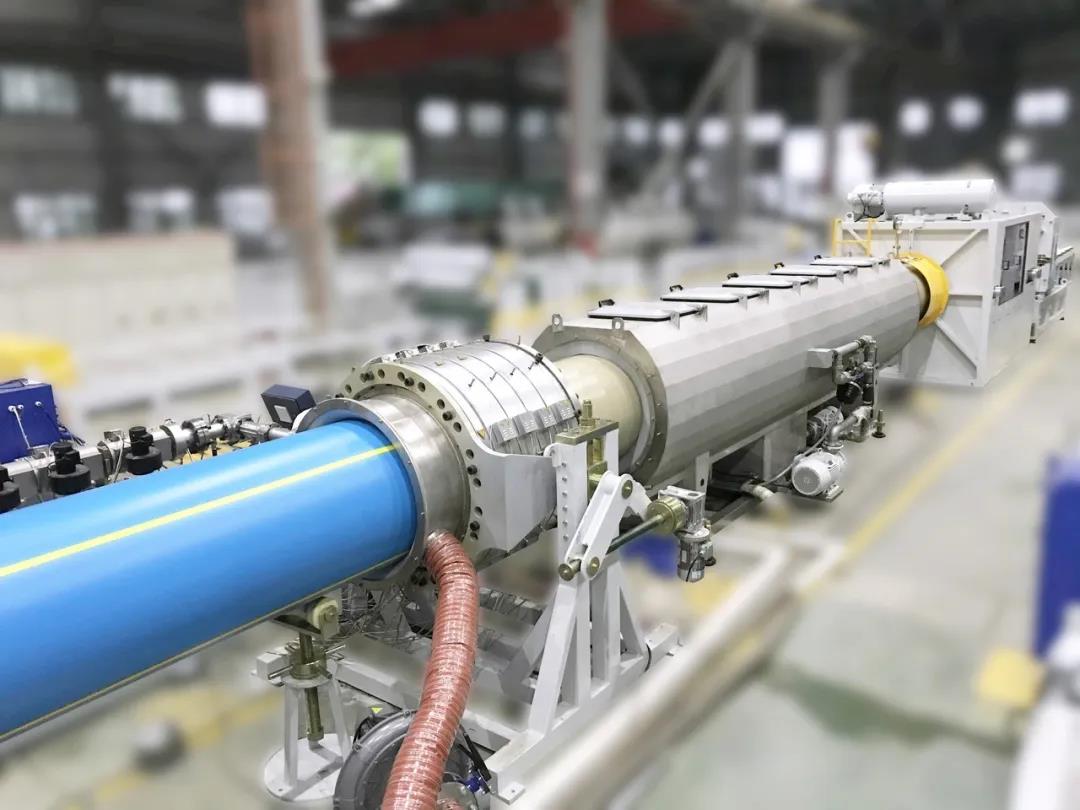

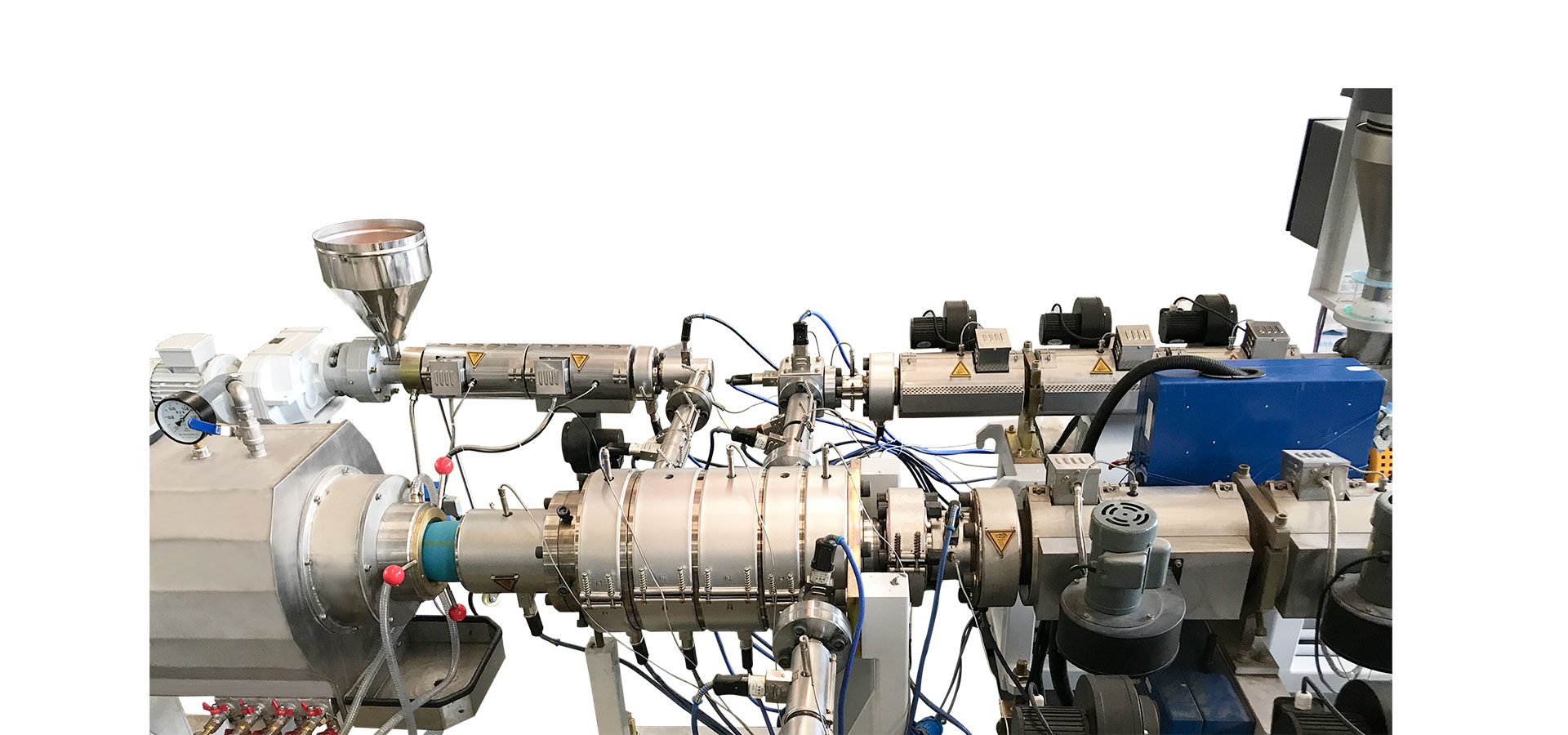

The die body adopts independent spiral mechanism of each layer to ensure the uniformity, and the exhaust mechanism ensures the stable melt temperature under high production and reduces the cooling length.

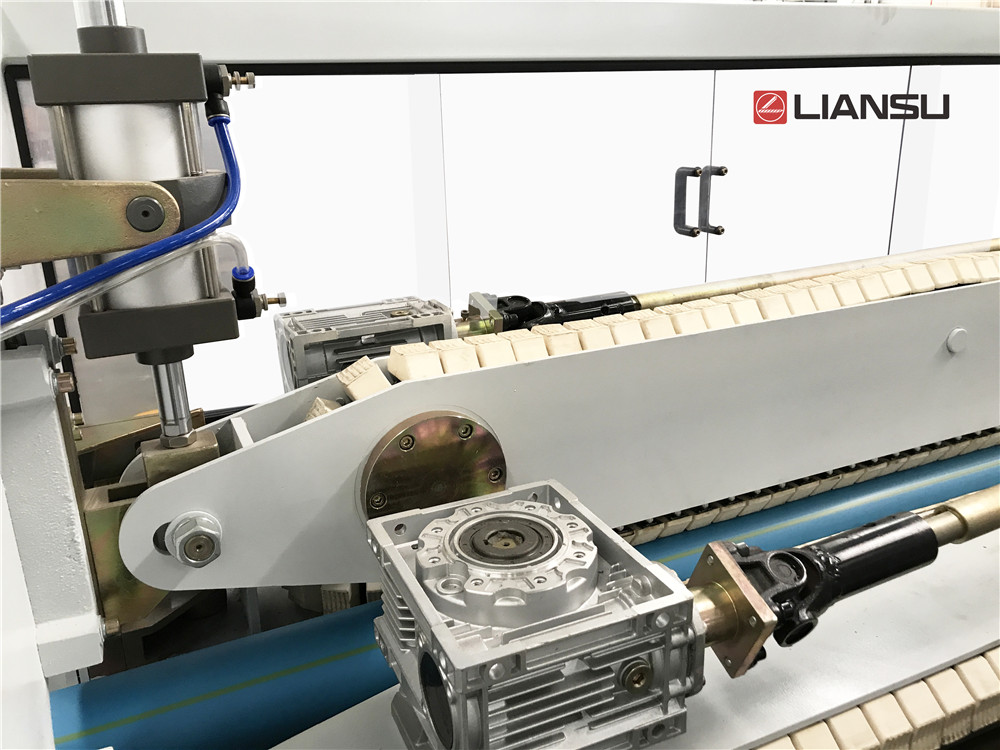

The hauling adopts servo control to ensure stable production in large speed range.

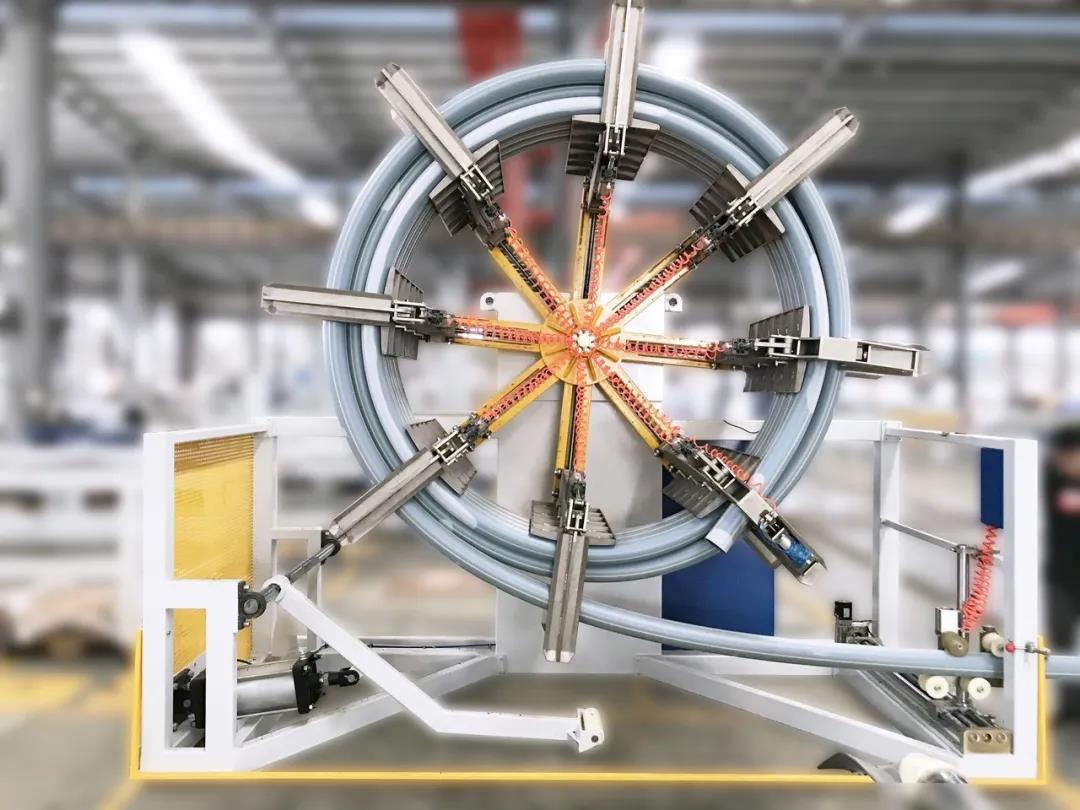

Equipped with online straight pipe, coil automatic packing mechanism, efficient and labour saving.

Production data acquisition and analysis system can be selected to realize transparent production management.

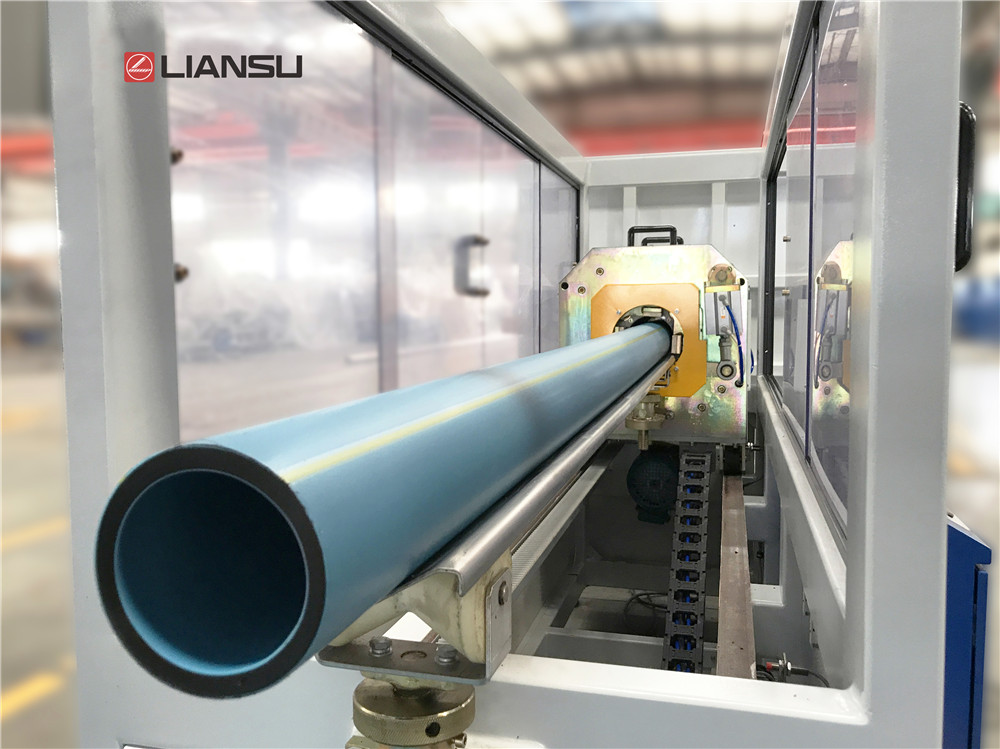

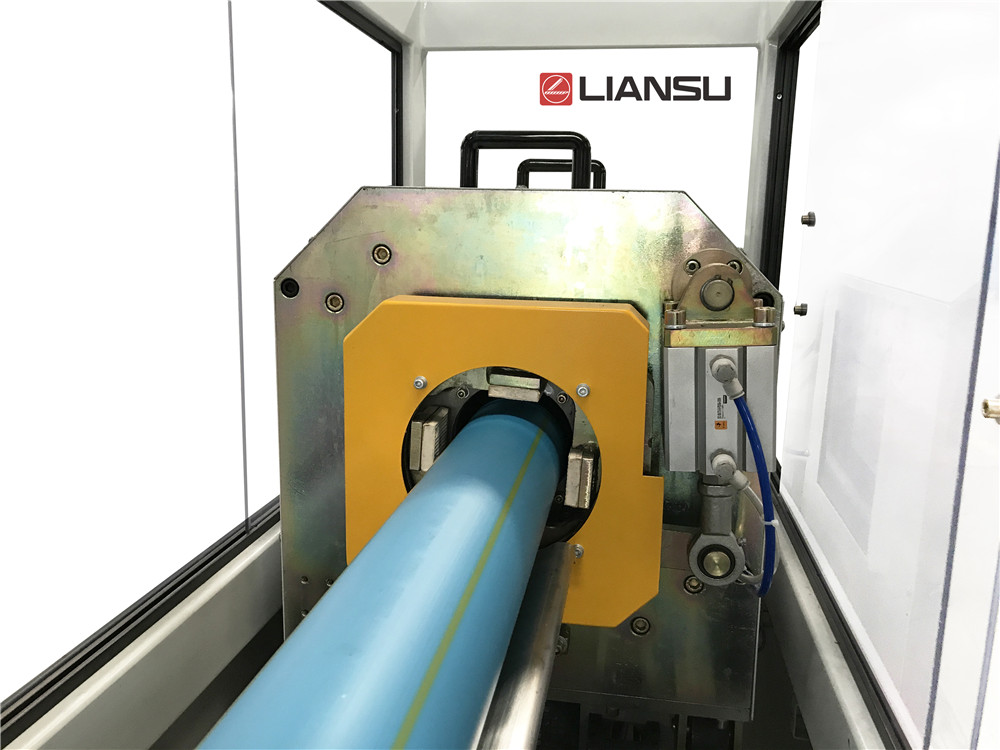

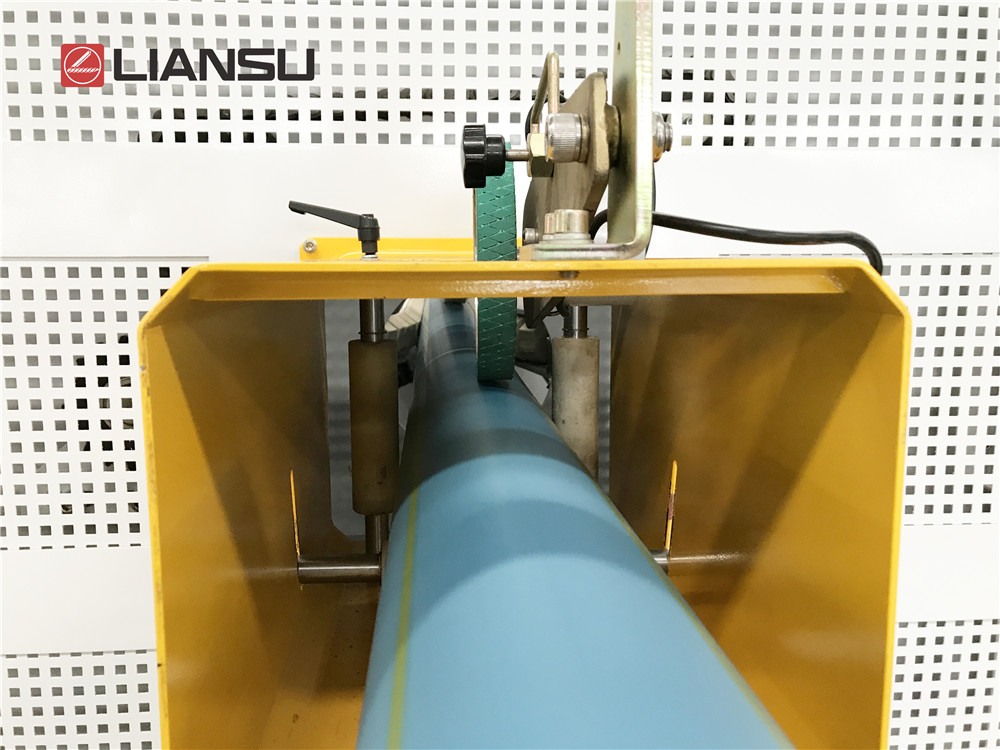

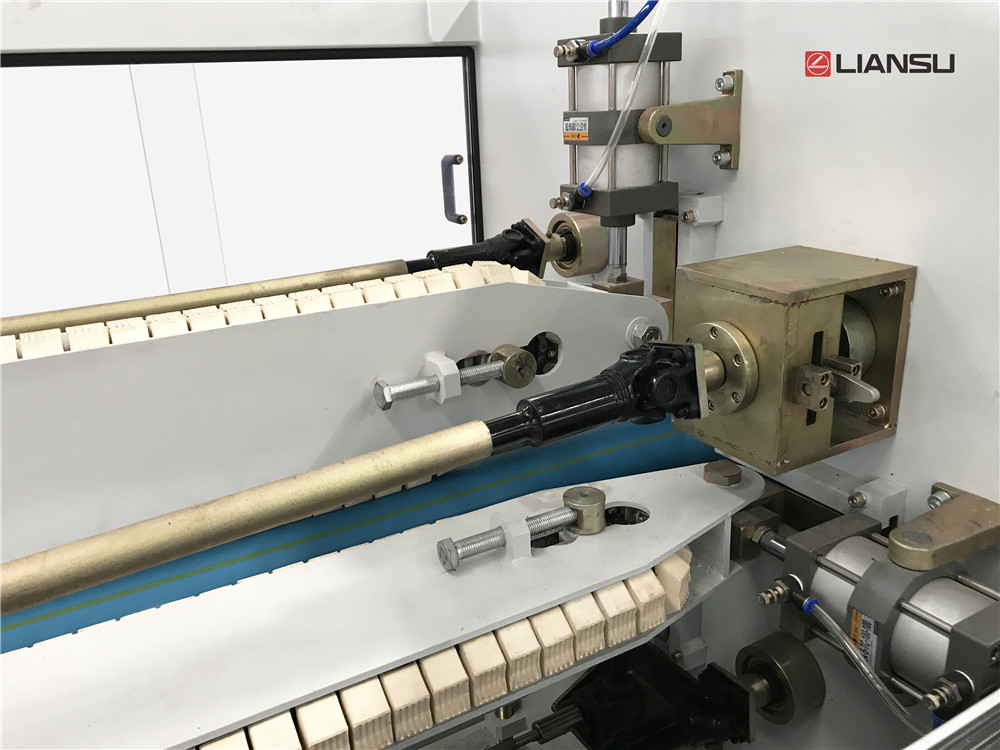

Adopt swarfless cutting mechanism, clear and accurate fixed length, beautiful incision.

The extruder adopts large L/D ratio screw and special permanent magnet synchronous servo motor for extruder to realize high production and energy saving.

The die body adopts independent spiral mechanism of each layer to ensure the uniformity, and the exhaust mechanism ensures the stable melt temperature under high production and reduces the cooling length.

The hauling adopts servo control to ensure stable production in large speed range.

Equipped with online straight pipe, coil automatic packing mechanism, efficient and labour saving.

Production data acquisition and analysis system can be selected to realize transparent production management.

Adopt swarfless cutting mechanism, clear and accurate fixed length, beautiful incision.

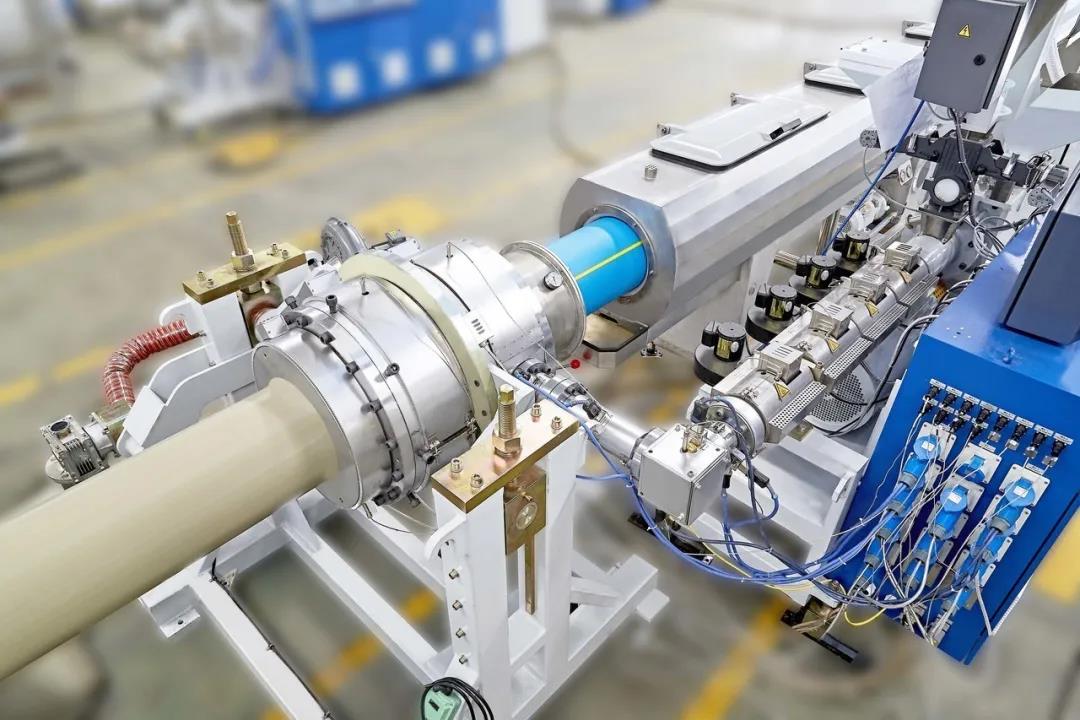

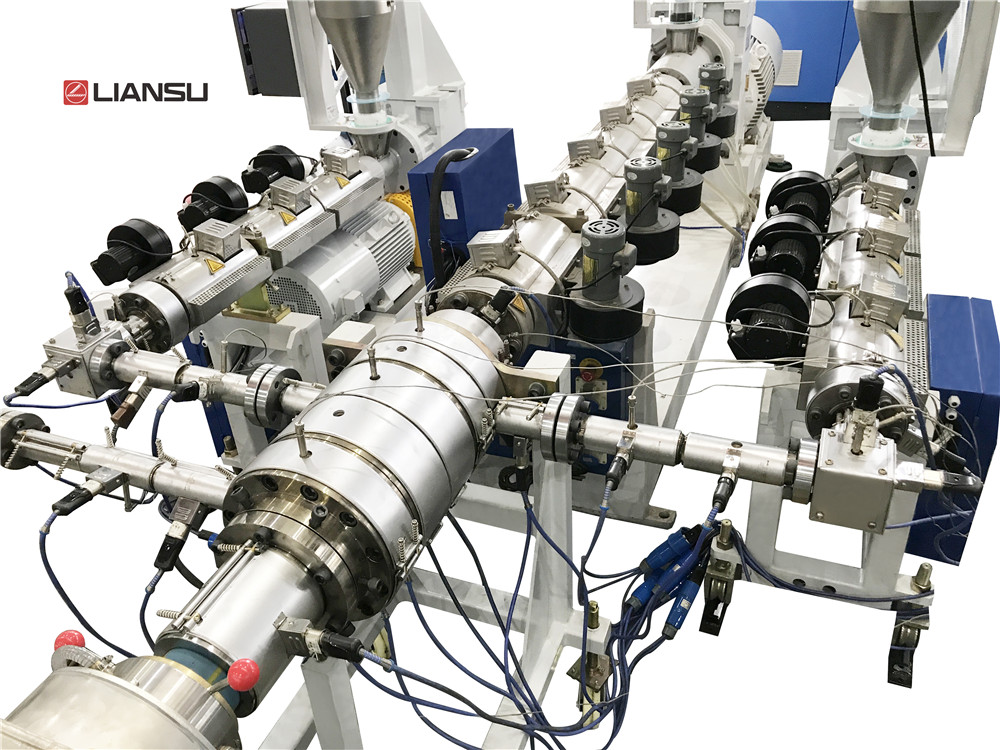

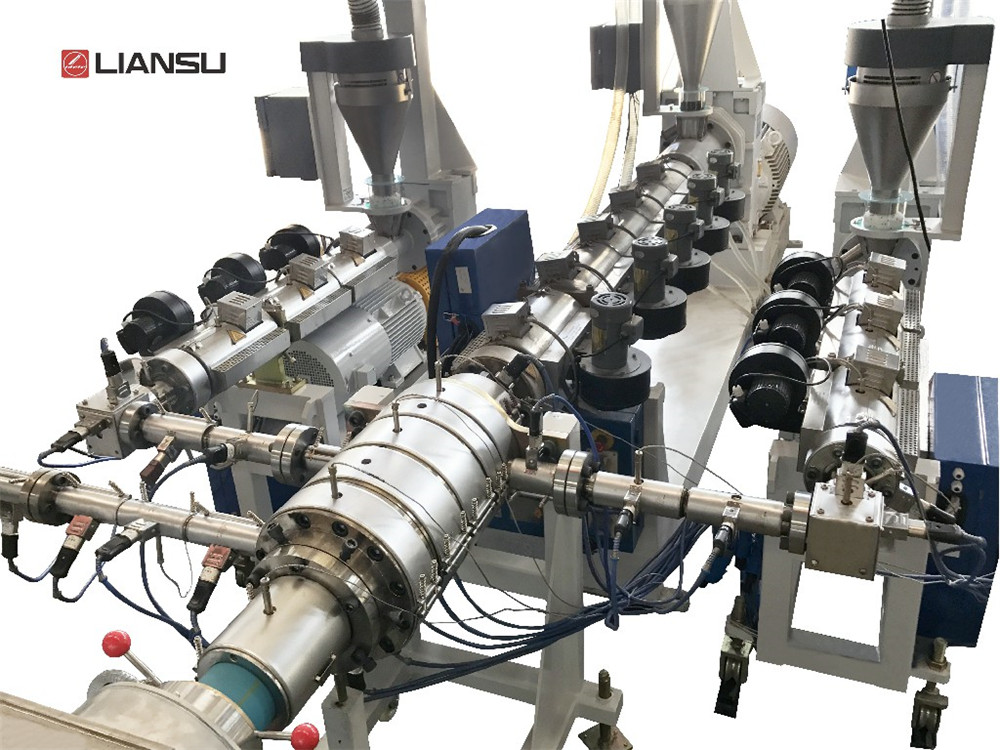

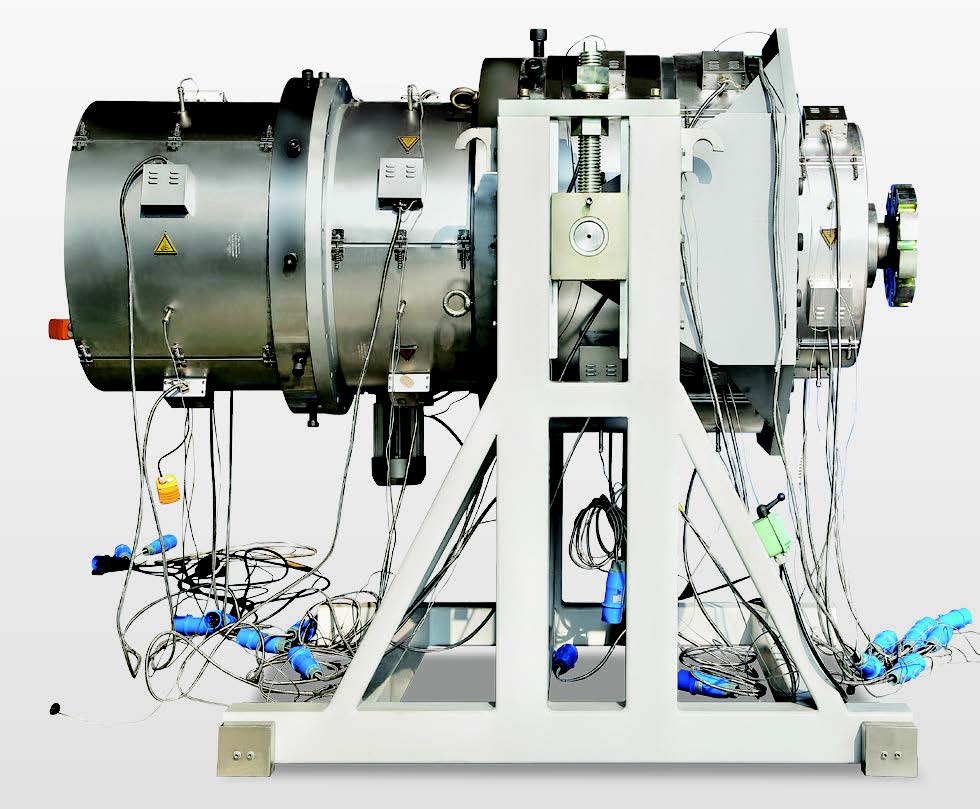

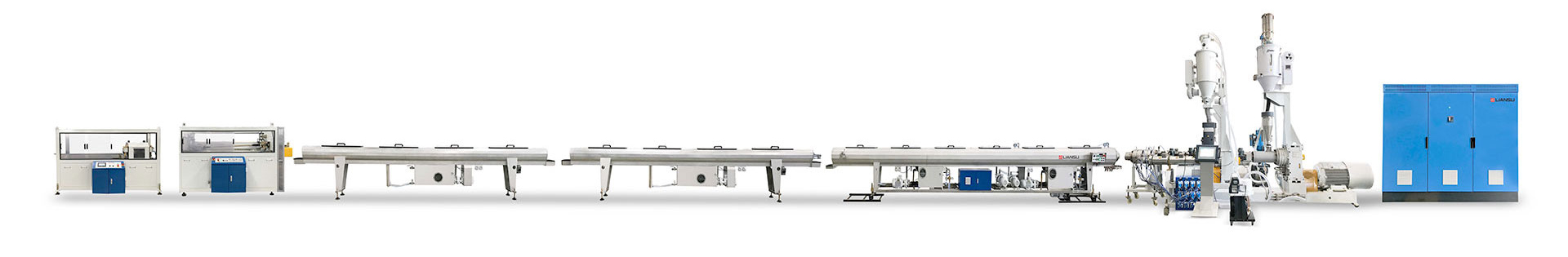

Extruder

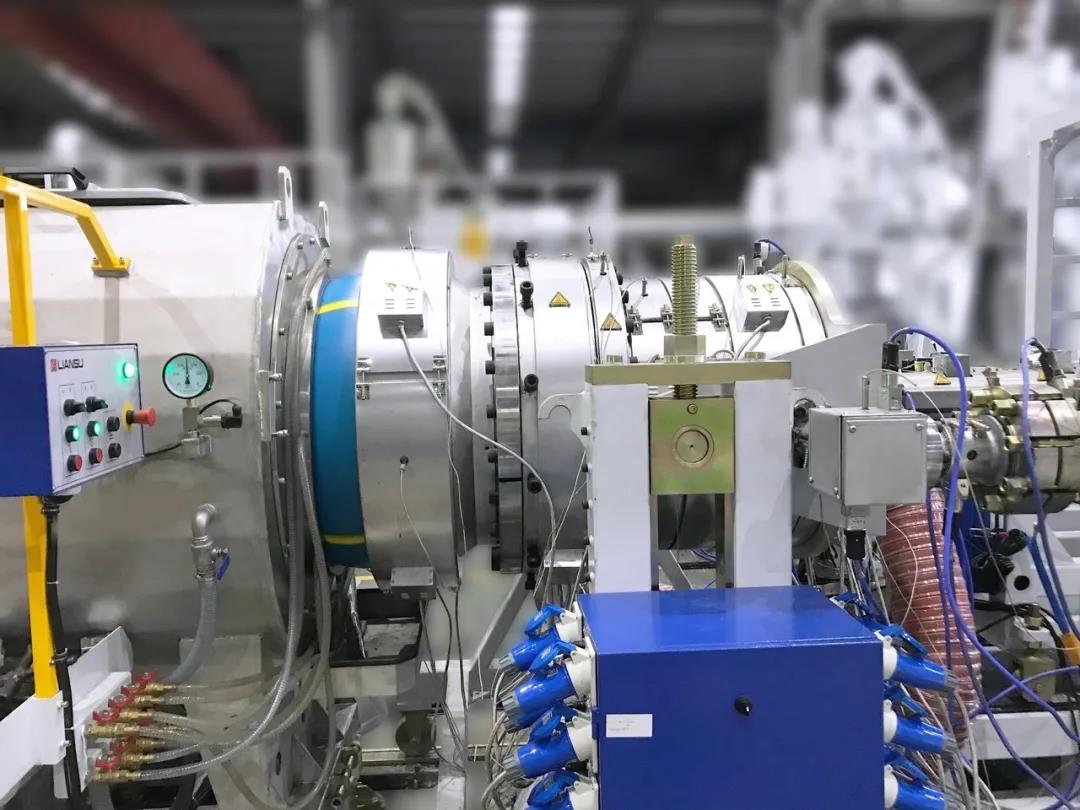

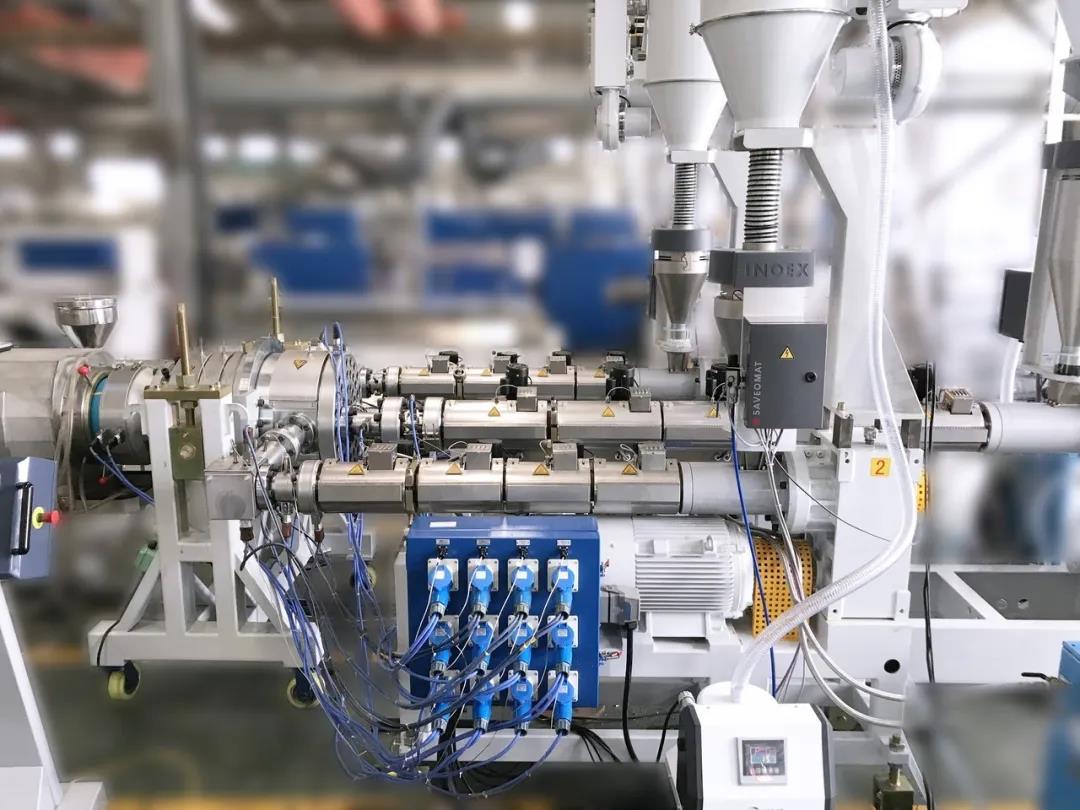

The extruder adopts extrusion dedicated permanent magnet synchronous servo motor, which saves installation space and is especially suitable for centralized placement of multiple extruders.

Low melt temperature design ensures good plasticizing effect.

PROFINET bus communication control of the whole line can avoid the influence of interference on each extruder, hauling and cutting transmission, and provide convenience for information collection.

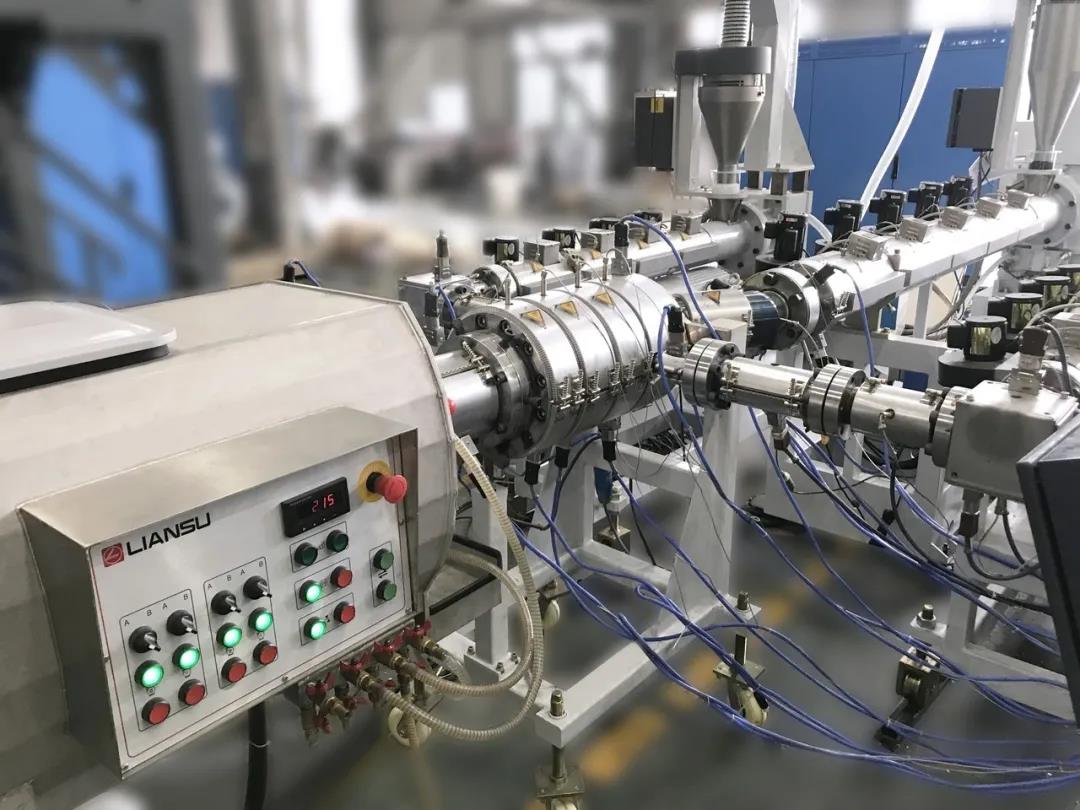

Extruder

The extruder adopts extrusion dedicated permanent magnet synchronous servo motor, which saves installation space and is especially suitable for centralized placement of multiple extruders.

Low melt temperature design ensures good plasticizing effect.

PROFINET bus communication control of the whole line can avoid the influence of interference on each extruder, hauling and cutting transmission, and provide convenience for information collection.Mould Design

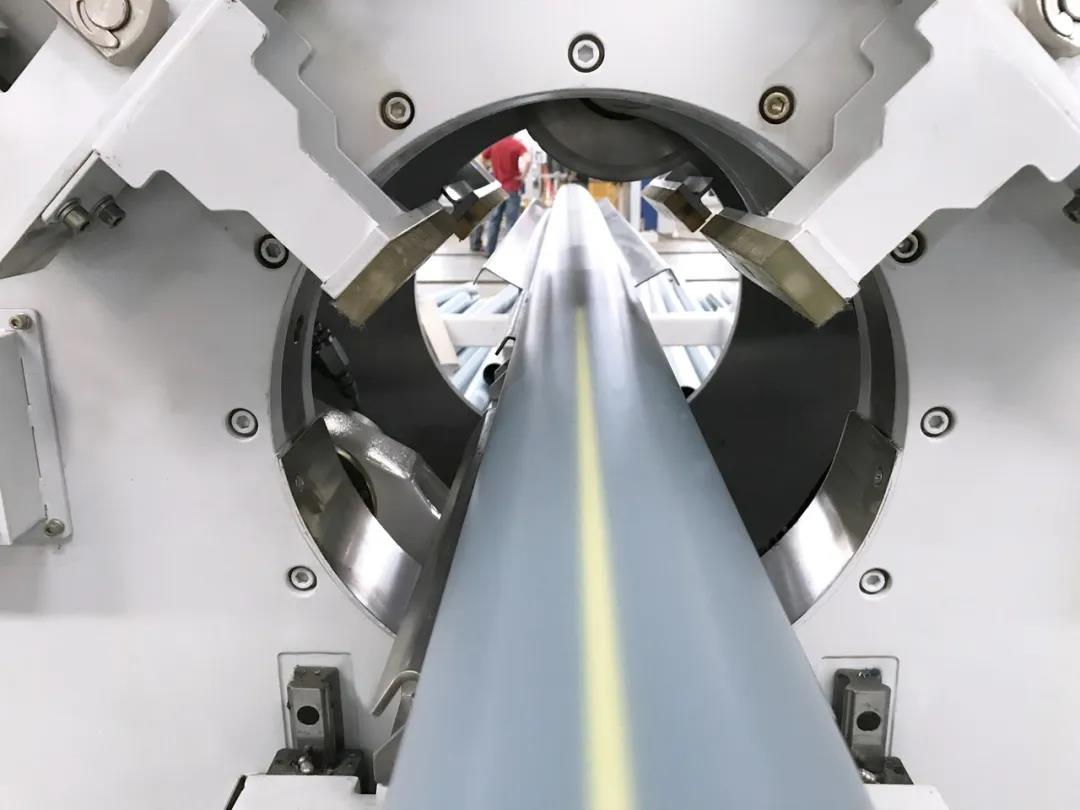

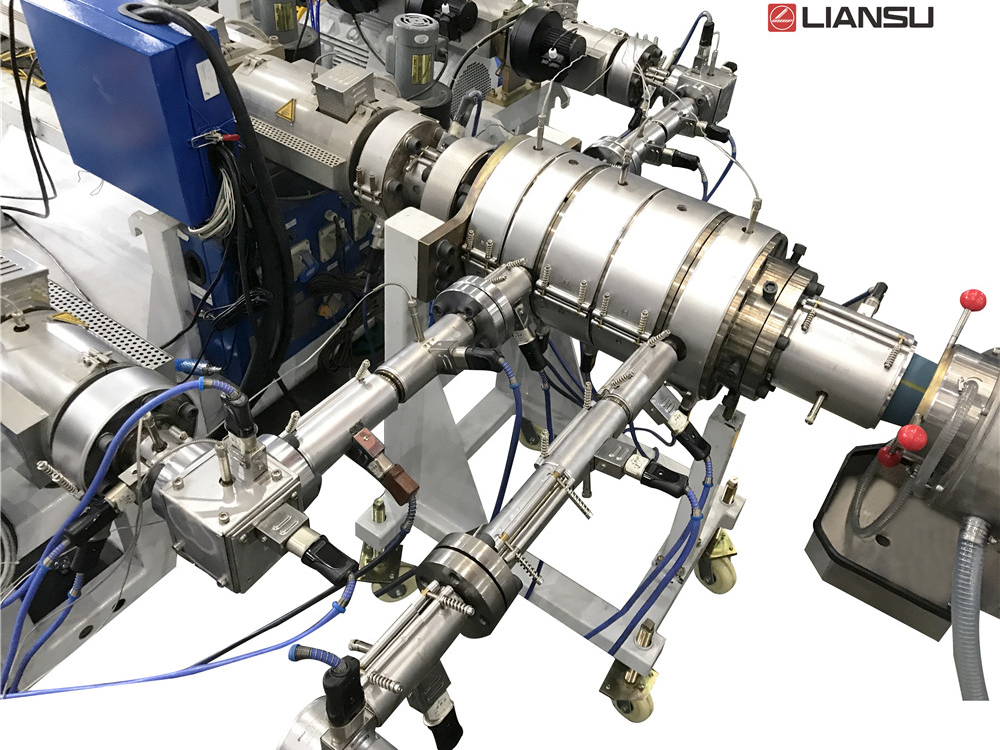

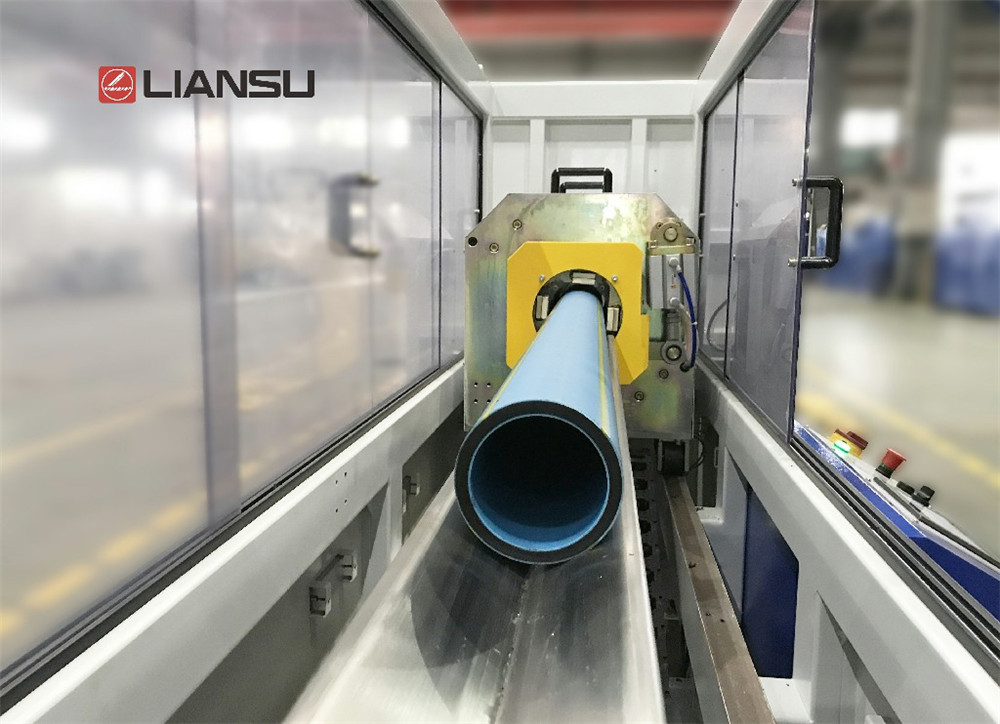

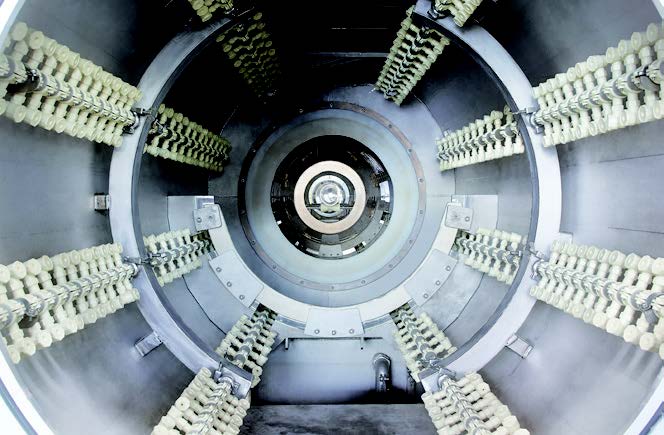

Die head adopts spiral basket structure, simple maintenance, accurate thickness of each layer.

Mould Design

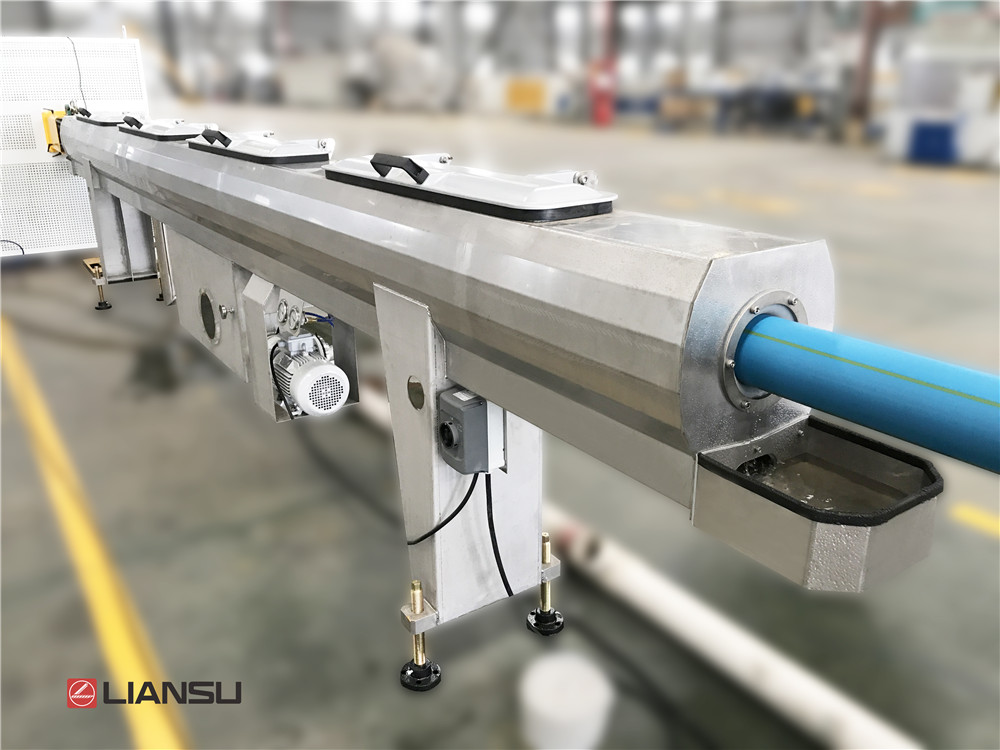

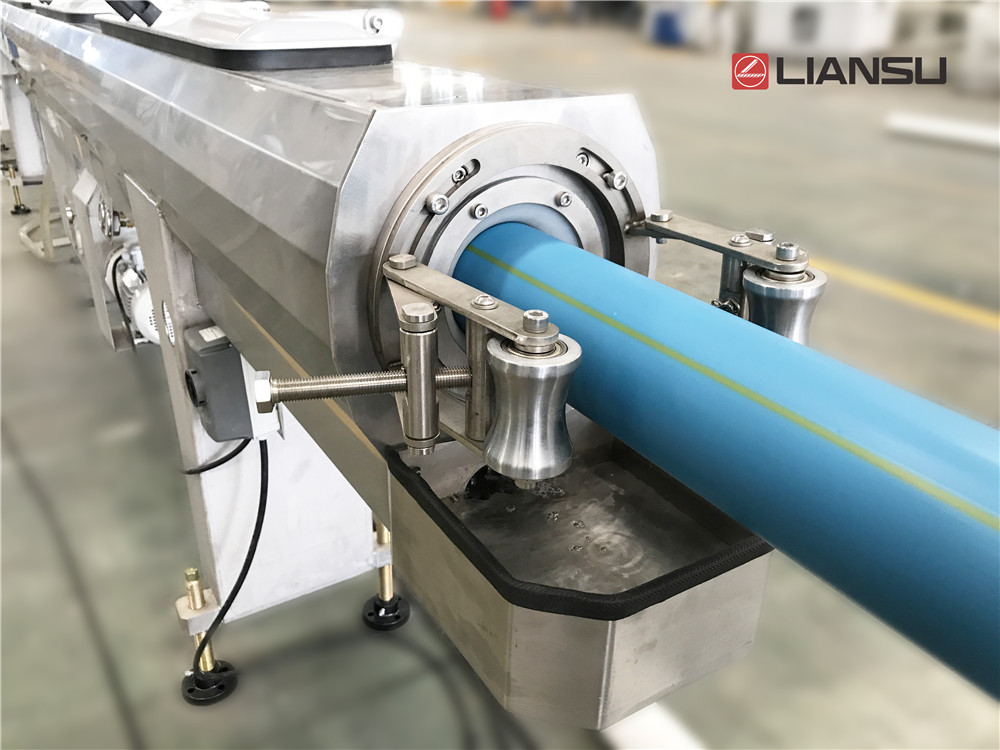

Die head adopts spiral basket structure, simple maintenance, accurate thickness of each layer..Vacuum Tank

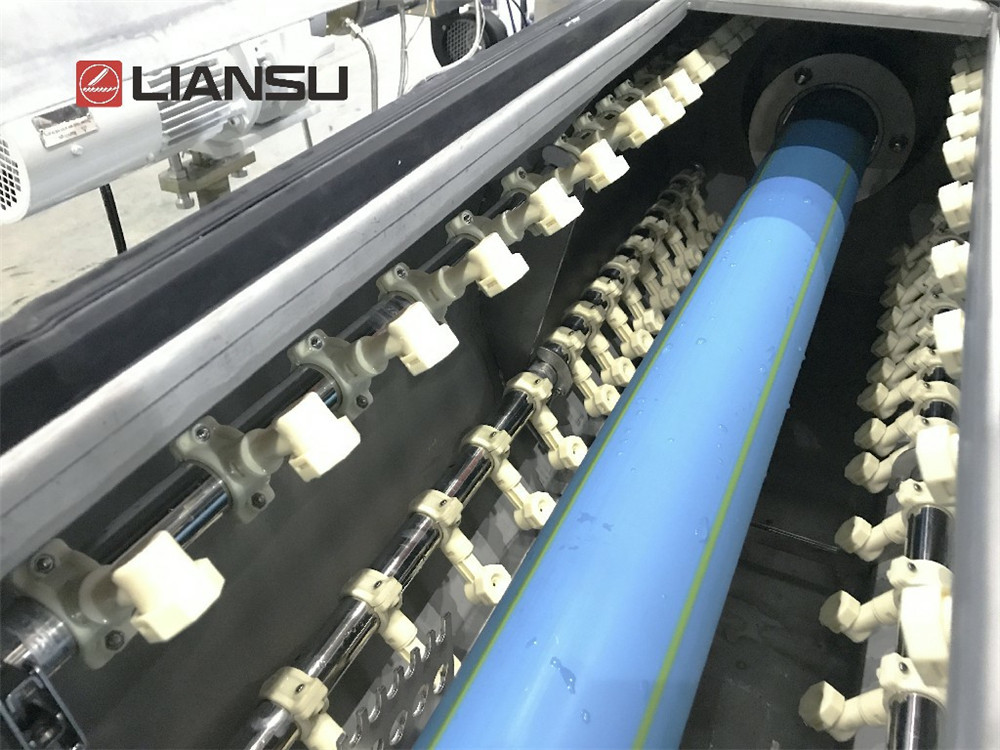

All vacuum of the whole line adopts negative pressure closed-loop automatic adjustment of vacuum degree, stable pressure, improve the quality of pipe production, low noise, energy saving 30 ~ 60%

Vacuum Tank

All vacuum of the whole line adopts negative pressure closed-loop automatic adjustment of vacuum degree, stable pressure, improve the quality of pipe production, low noise, energy saving 30 ~ 60%Haul-off Unit

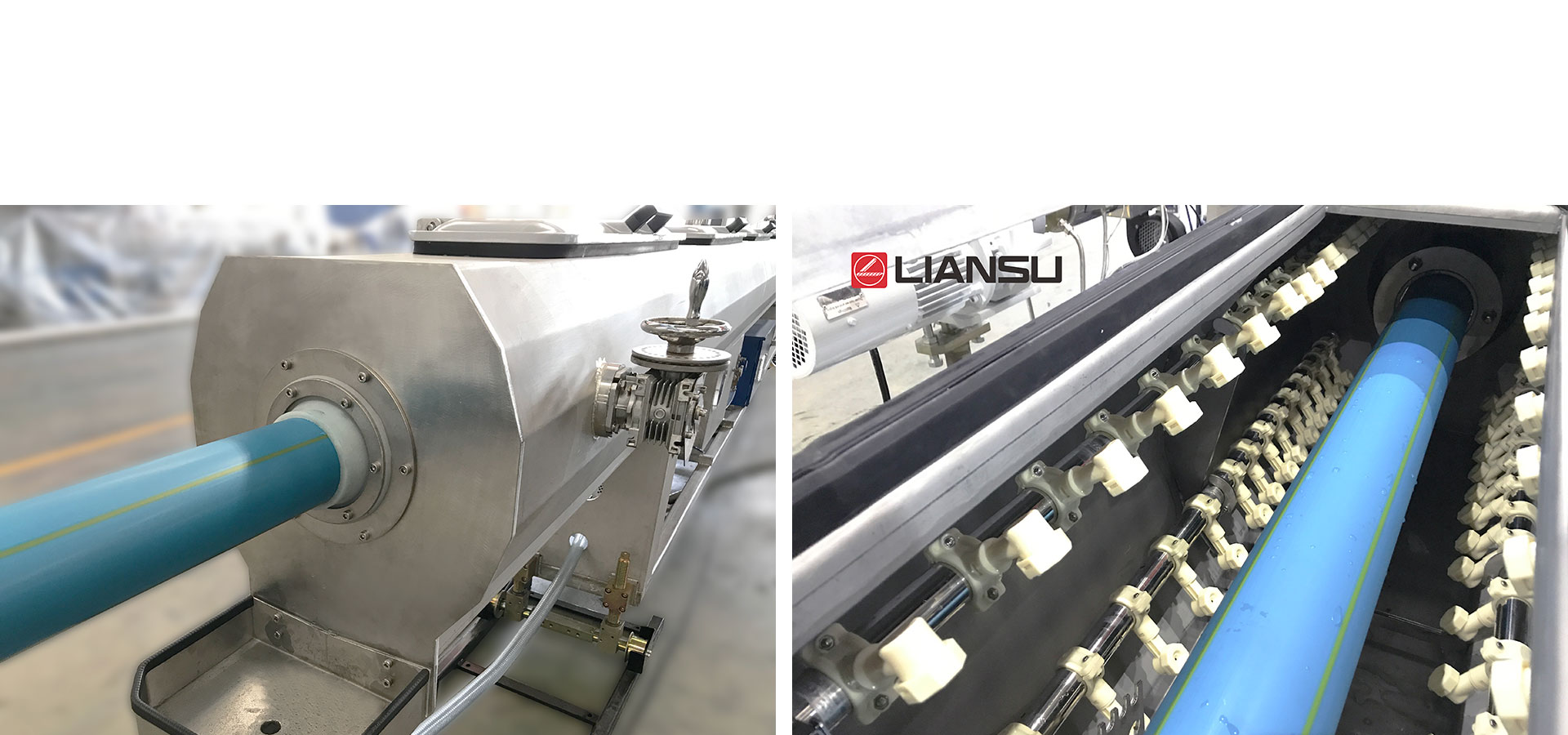

The permanent magnet synchronous motor is adopted in the hauling machine to ensure a stable speed regulation range of more than 50 times, so as to realize the stable hauling of pipe.Cutter

Single or double blade swarfless cutting, stable cutting, can cut thin pipe, especially thick pipe.

Electric cam control cutting cart, fixed length precisely, cutting stable.

Cutter

Single or double blade swarfless cutting, stable cutting, can cut thin pipe, especially thick pipe.

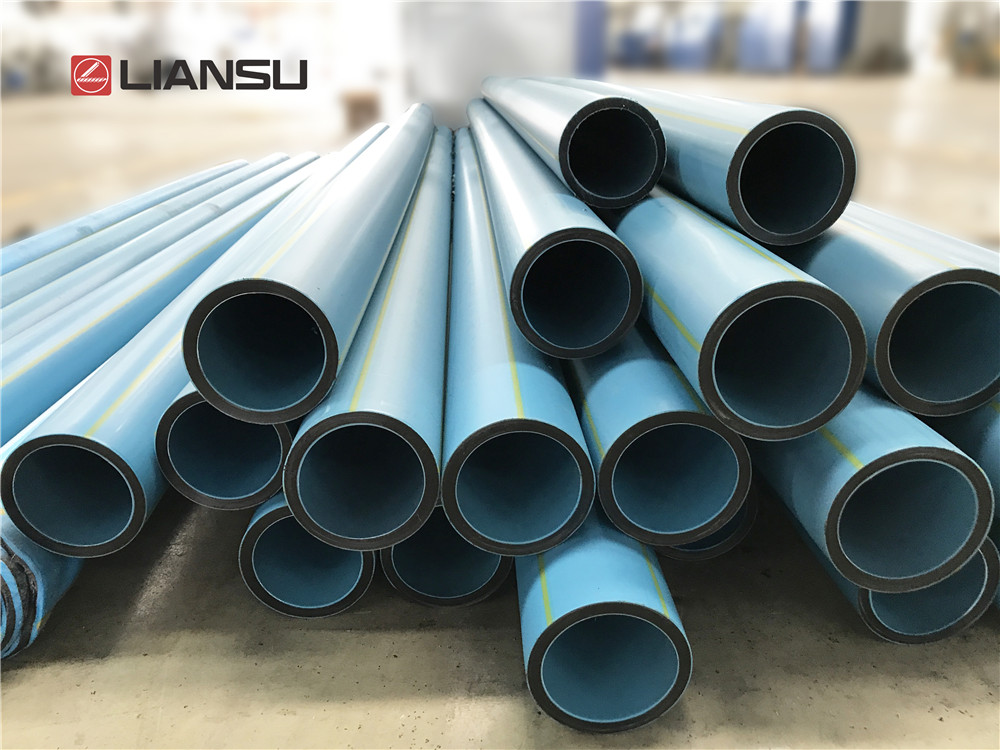

Electric cam control cutting cart, fixed length precisely, cutting stable.Sample

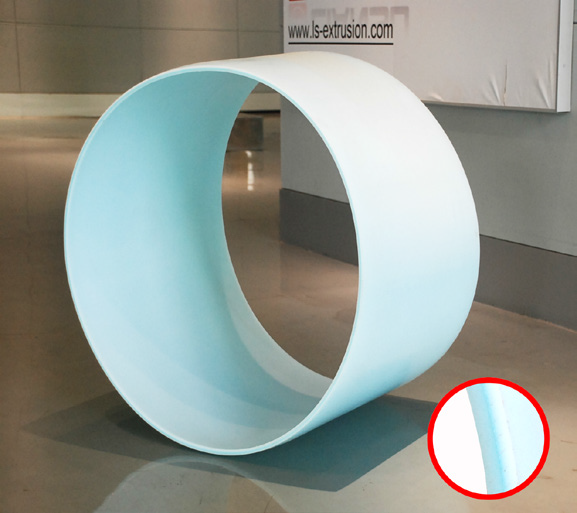

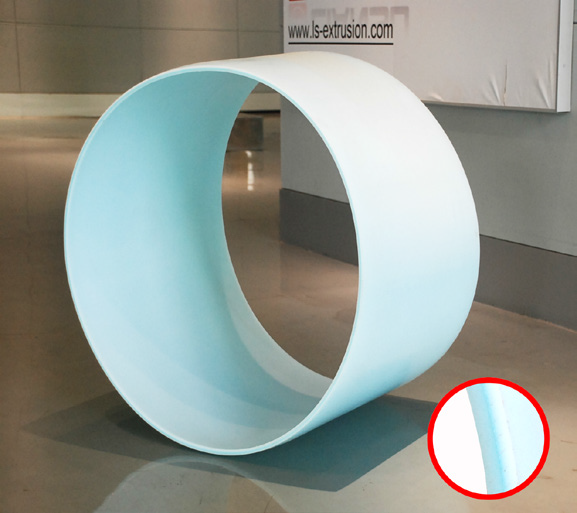

- Ø800mm Five-layer PERT insulation pipe

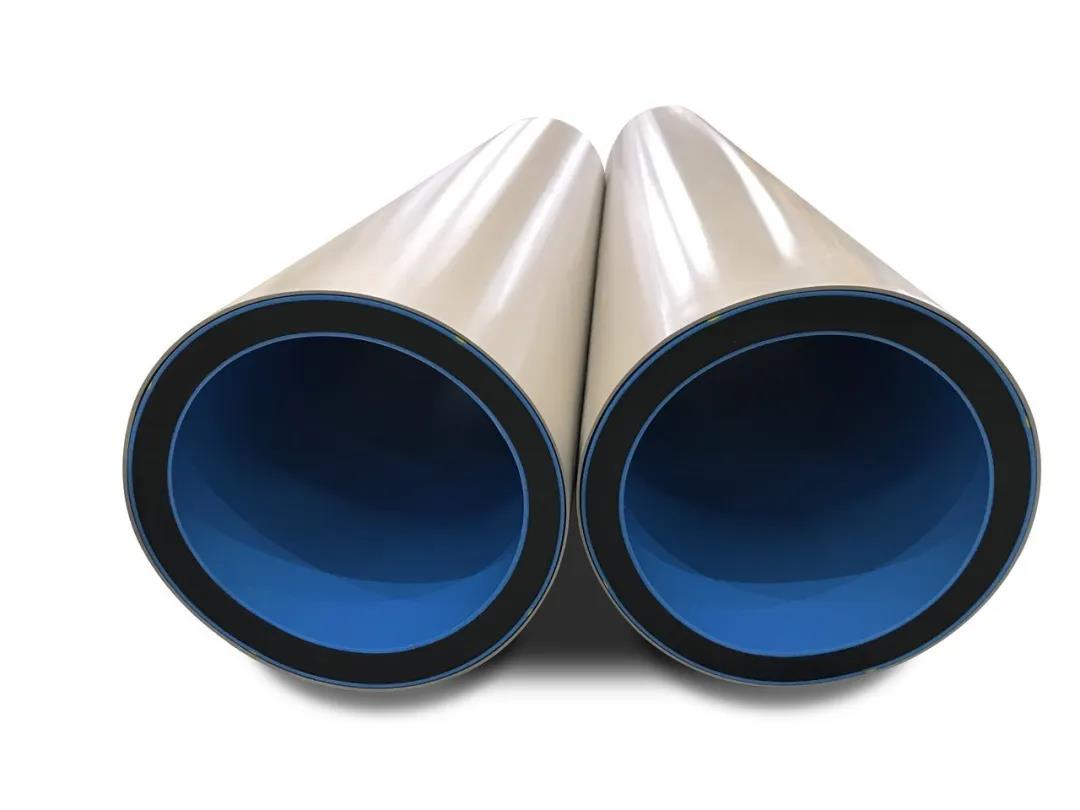

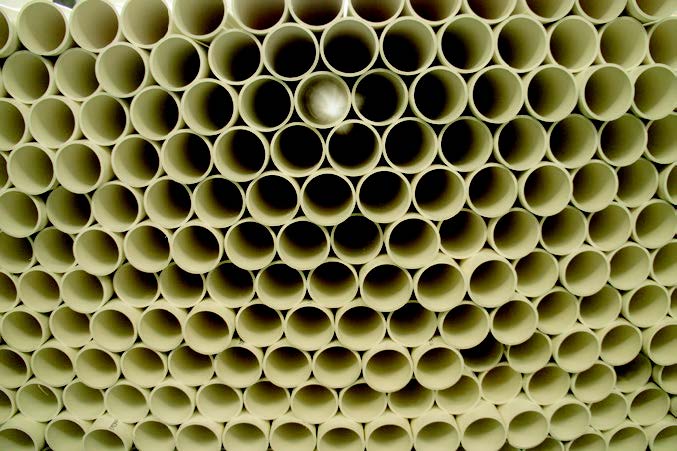

- Three-layer polyethylene pipe

-

-

- Ø800mm Five-layer PERT insulation pipe

- Three-layer polyethylene pipe

-

-

-

20-315мм HDPE Multi-Layer Pipe Production Line

3 Layer Coextrusion HDPE Pressure Pipe Line

Moscow, Russia