Volokolamskoye shosse 89 bld 1,

Moscow, Russia

- You are here:

-

Home

-

Products

-

Auxiliary machine

-

Granulator

- Pelletizing Line

-

-

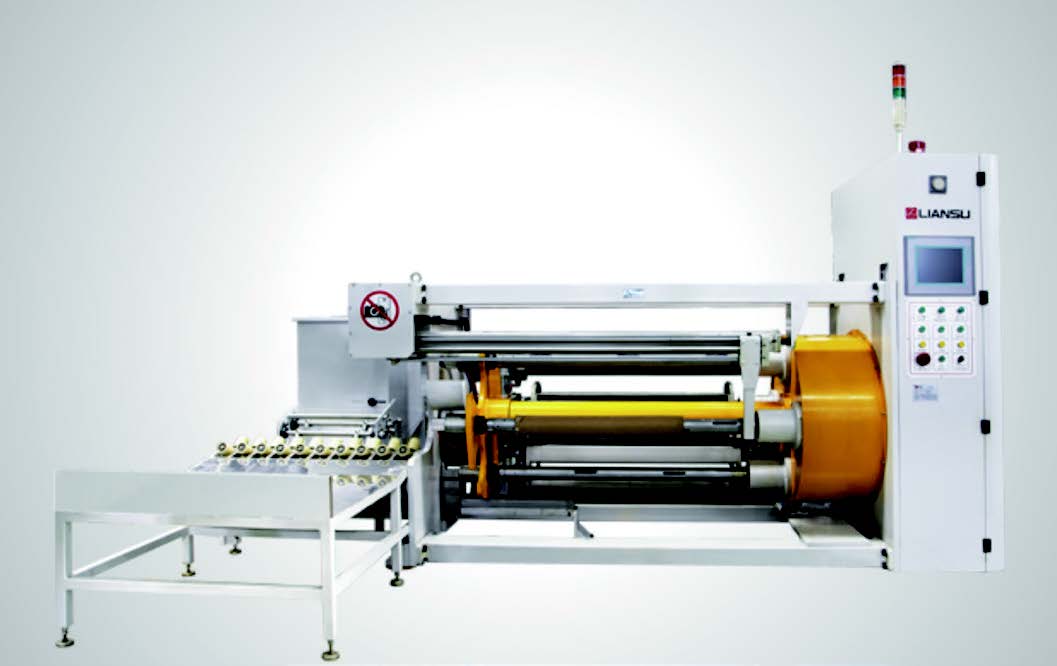

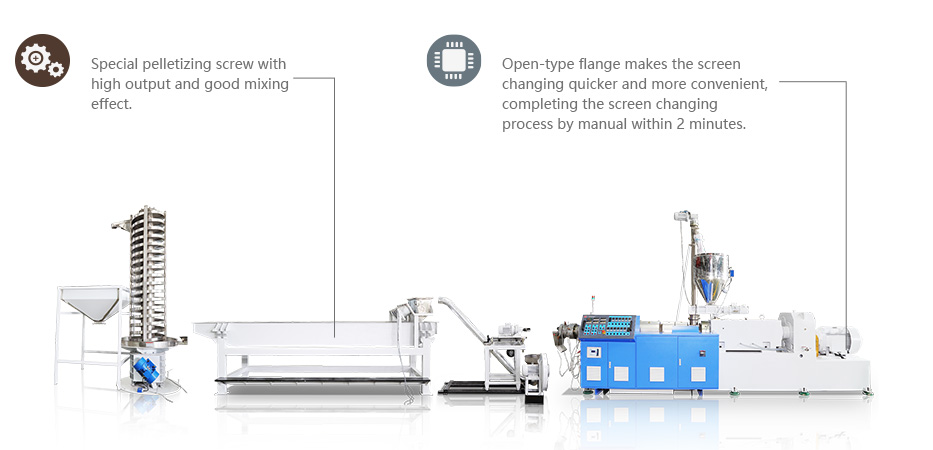

MODEL OUTPUT (kg/h) TOTAL POWER (kw) EXTRUDER GRANULATING TYPE LSE-65PVC 280 88 LSE-65 Die head LSE-80PVC 450 170 LSE-80 Die head LSE-92PVC 800 250 LSE-92 Die head

MODEL OUTPUT (kg/h) GRANULE SIZE TOTAL INSTALLED POWER (kw) EXTRUDER GRANULATING TYPE LSZL-65PPR 280 Ø3 88 LSE-65 Cold cut LSZL-80 450 Ø3 170 LSE-80 Cold cut LSZL-100PE 800 Ø3 250 LSE-92 Water ring cutting -

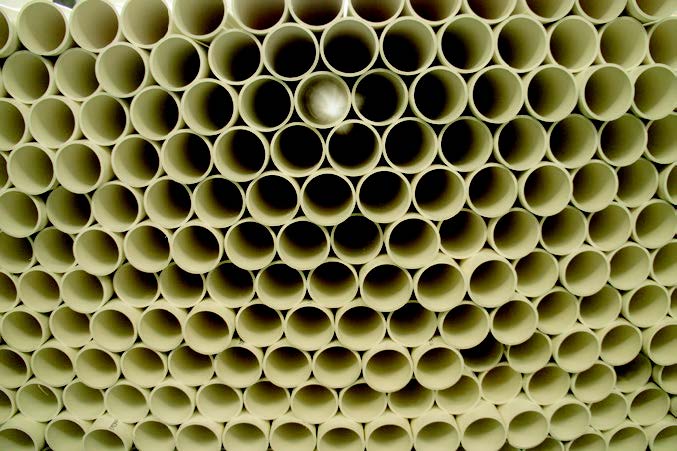

PVC

MATERIAL

250-1000

MAX OUTPUT (kg/h)

88-250

TOTAL INSTALLED POWER (kw)

LS-Pelletizing Production Line

PVC

MATERIAL

250-1000

MAX OUTPUT (kg/h)

88-250

TOTAL INSTALLED POWER (kw)

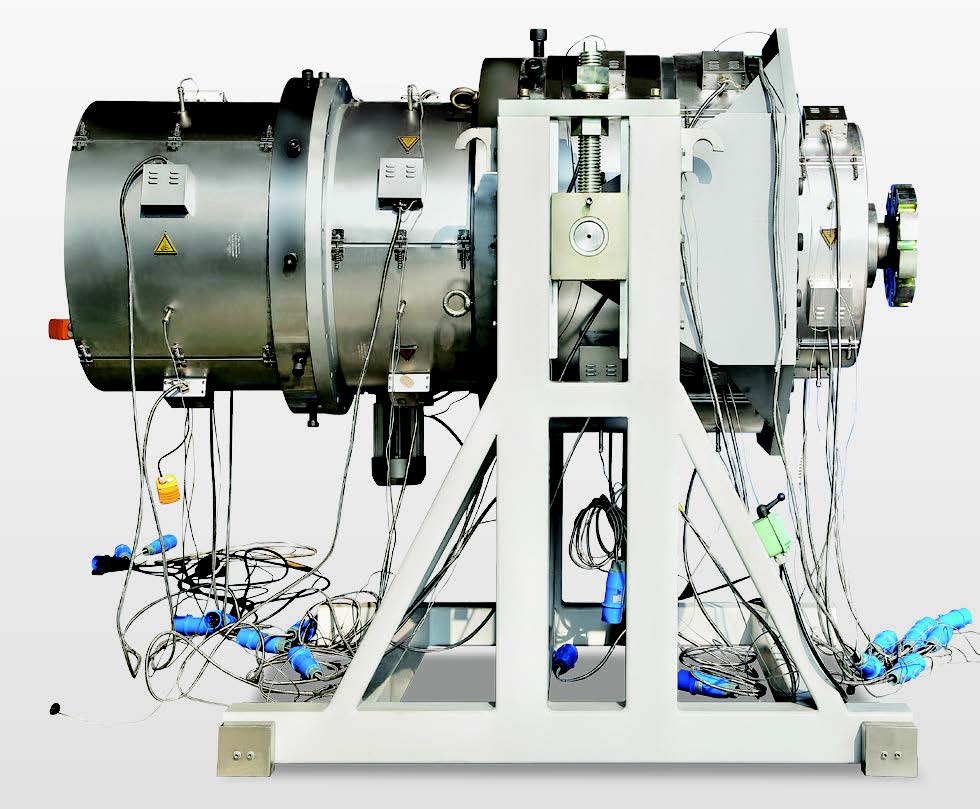

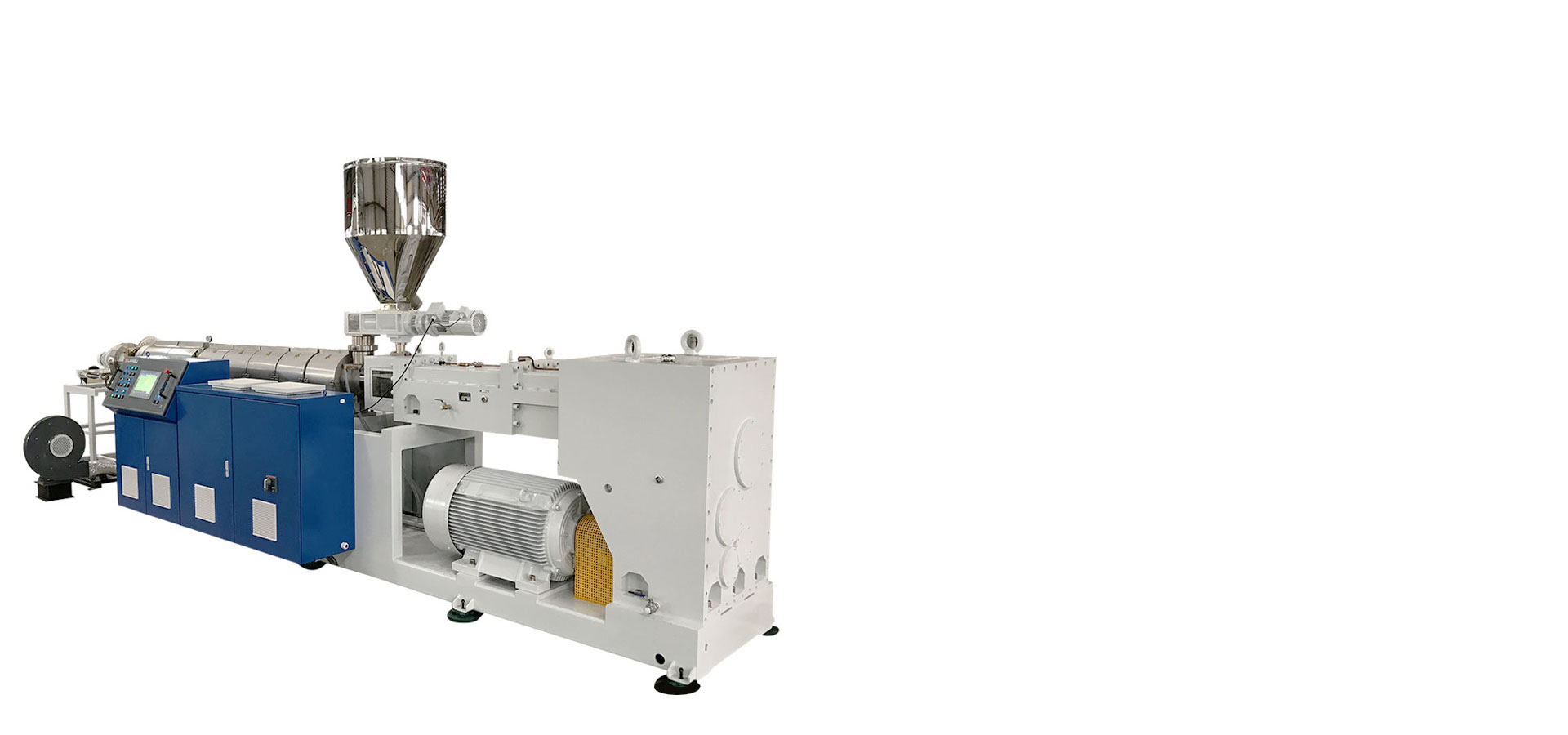

ExtruderCompared with the conventional AC asynchronous motor, the permanent magnet synchronous servo motor for extruder can reduce 1 ~ 2 power levels, reduce noise and save energy by 10 ~ 20%. It is equipped with high-output conical double-screw or parallel twin-screw, and the output is as high as 1 kW and 13.5 kg.

It can add toner online and change color flexibly.

It is suitable for stable production of calcium zinc stabilizer.

MouldSimple die structure ad stable flow avert of the material remaining in the mould.

Open type flange makes the screen changing quicker and more convenient, completing the screen changing process by manual within 2 minutes.

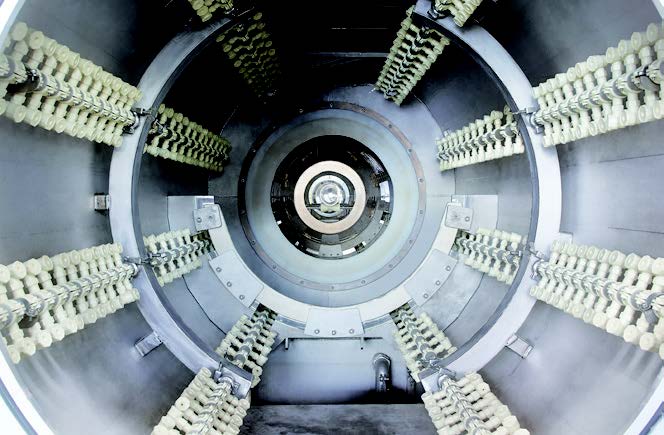

Cooling Device

Horizontal vibrating conveyor

Sample

Subscribe to our channel

Subscribe to our channel

© Liansu 2024,